A kind of adsorption and recovery of CO in flue gas with high sulfur content 2 s installation

An adsorption recovery, high-sulfur technology, applied in gas treatment, calcium carbonate/strontium/barium, separation methods, etc., can solve the problems of affecting the oxidation of sulfite, the effect is not significant, in the laboratory stage, etc., to achieve low cost , the effect of strong economic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

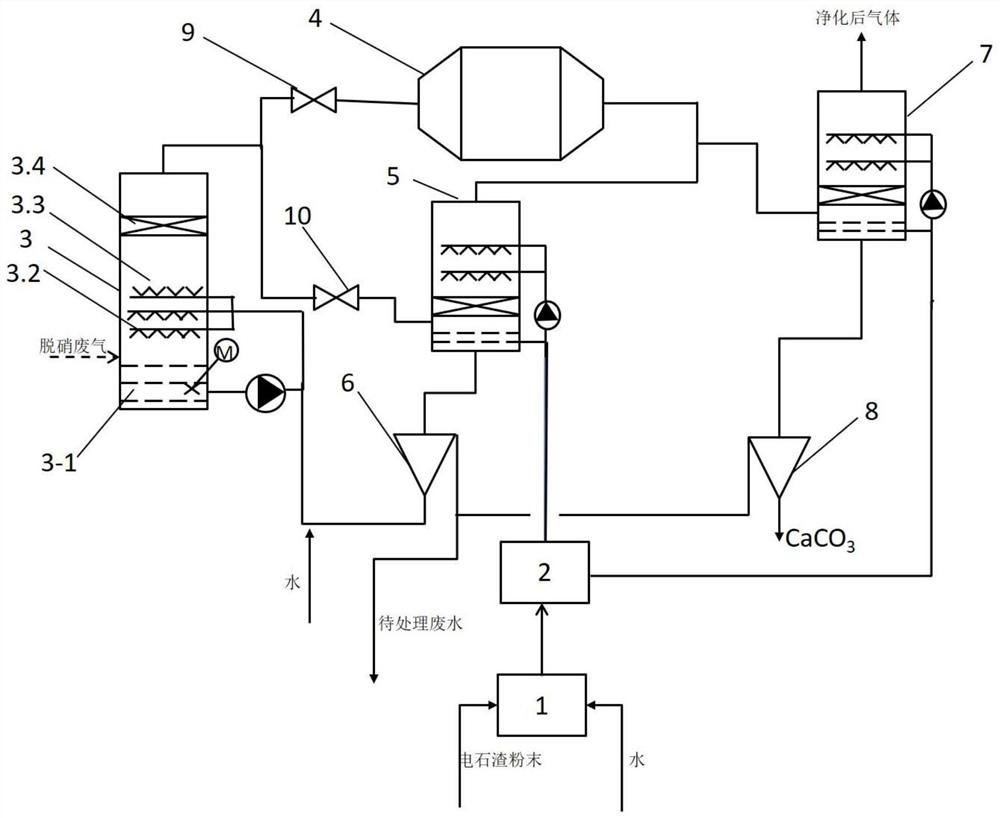

[0034] The present invention will now be described in further detail with reference to the accompanying drawings and examples. The drawings are simplified, and the basic configuration of the present invention is illustrated in a schematic manner, and therefore it only shows the configurations related to the present invention.

[0035] The device employed in this example is figure 1 As shown, a desulfurization decaplation device having a high sulfur flue gas is used to deinterlearburize the denitrifination, the device comprising a dissolved tank 1, a magnetic separator 2, a desulfurization tower 3, an adsorber 4 , Decarbonate tower 5, settling pool 6, refine tower 7 and essence 8; wherein the desulfurization tower is sequentially provided from top to bottom, and the injection pipe 3-3, spray tube 3-2, tower 3-2, tower Internal oxidation tank 3-1, the tower oxidation pond 3-1 is connected to the spray tube 3-3, the spray tube 3-2 is connected by the outer slurry circulation pipe, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com