A kind of adsorption and recovery of CO in flue gas with high sulfur content 2 Methods

An adsorption recovery, high-sulfur technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems affecting the oxidation of sulfite, the effect is not significant, and it is in the laboratory stage, etc., to achieve low cost and strong Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

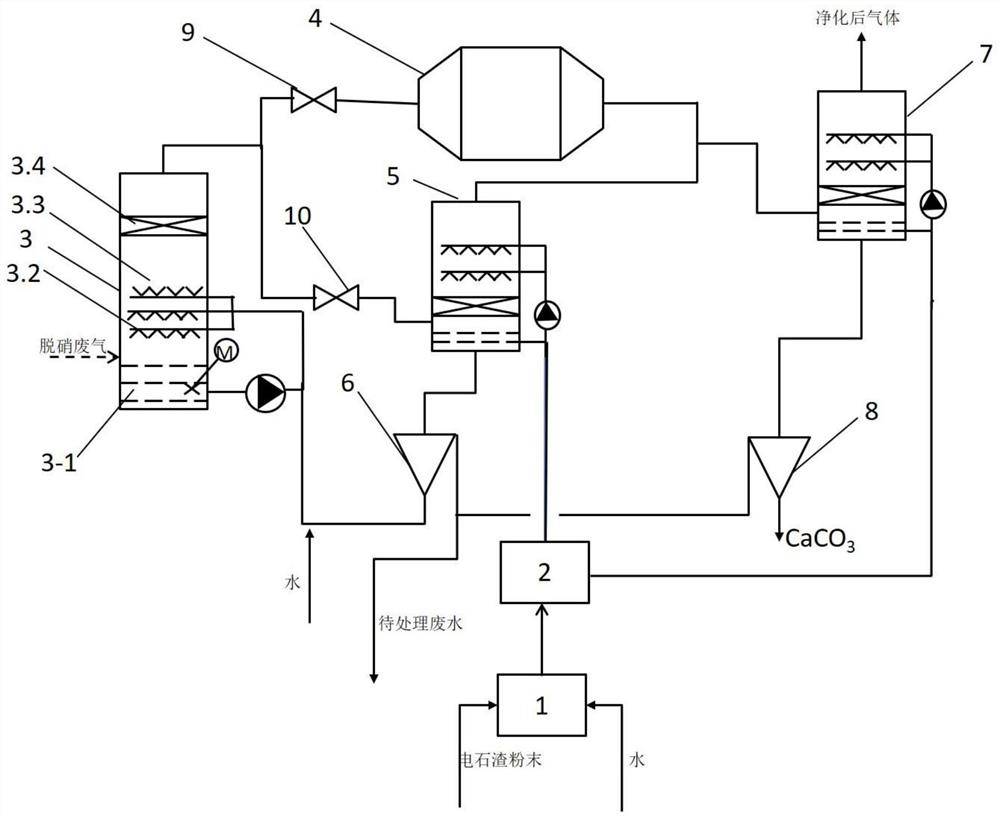

[0034] The present invention is described in further detail now in conjunction with accompanying drawing and embodiment. This drawing is a simplified schematic diagram, which only illustrates the basic structure of the present invention in a schematic manner, so it only shows the constructions related to the present invention.

[0035] The device used in this example is figure 1 As shown, it includes a dissolution tank 1, a magnetic separator 2, a desulfurization tower 3, an adsorber 4, a decarbonization tower 5, a settling tank 6, a fine desulfurization tower 7, and a fine settling tank 8; wherein the desulfurization towers are arranged sequentially from top to bottom Demister 3-4, injection pipe 3-3, spray pipe 3-2, oxidation tank 3-1 in the tower, oxidation tank 3-1 in the tower through the external slurry circulation pipeline and injection pipe 3-3, spray The pipe 3-2 is connected, and the outlet pipe at the top of the desulfurization tower is divided into two, one of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com