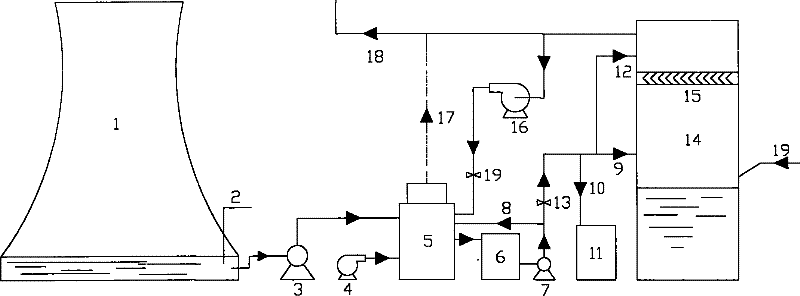

A method of using cooling tower circulating water as water for flue gas desulfurization system

A desulfurization system and circulating water technology, applied in the field of resources and the environment, can solve problems such as easy adhesion to the demister, easy scaling, and large water consumption, so as to reduce water consumption, prolong the scaling cycle, reduce resource consumption and The effect of economic input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A power plant has 7 sets of 130t / h boilers, the cooling tower circulating water control concentration rate is 2, the pH value is 8.2, the chloride ion is 480mg / L, the calcium ion is 250mg / L, the phosphorus is 1.56mg / L, and the total alkalinity is 8.2mmol / L, the amount of sewage discharged before the transformation was 200t / h, the water consumption of the desulfurization system was 100t / h, and the amount of sewage discharged met the water consumption for desulfurization; The water consumption is reduced by 100t / h, the transformation cost is 100,000 yuan, the annual water consumption is reduced by about 240,000 yuan, and the desulfurizer cost is reduced by 29,000 yuan. The system and equipment are operating normally.

Embodiment 2

[0031] There are three 420t / h boilers in a power plant, the cooling tower circulating water control concentration rate is 3, the pH value is 8.0, the chloride ion is 675mg / L, the sodium ion is 3296mg / L, the calcium ion is 498mg / L, and the total alkalinity is 17.9mmol / L, before the transformation, the sewage discharge volume was 170t / h, and the water consumption of the desulfurization system was 120t / h. The sewage discharge volume met the desulfurization water consumption. Reduce 120t / h, the transformation cost is 158,000 yuan, the annual reduction of water consumption is equivalent to 332,000 yuan, and the cost of desulfurization agent is reduced by 39,000 yuan. The system and equipment are operating normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com