In situ synthesis of nano-sulfur-iron hybrid biofilm electrode and its preparation method and application

A biomembrane electrode and in-situ synthesis technology, which is applied in chemical instruments and methods, biological water/sewage treatment, special compound water treatment, etc., can solve the problem of low cathode electron transfer efficiency and achieve large-capacity adsorption and synthesis capacity Multiple and excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

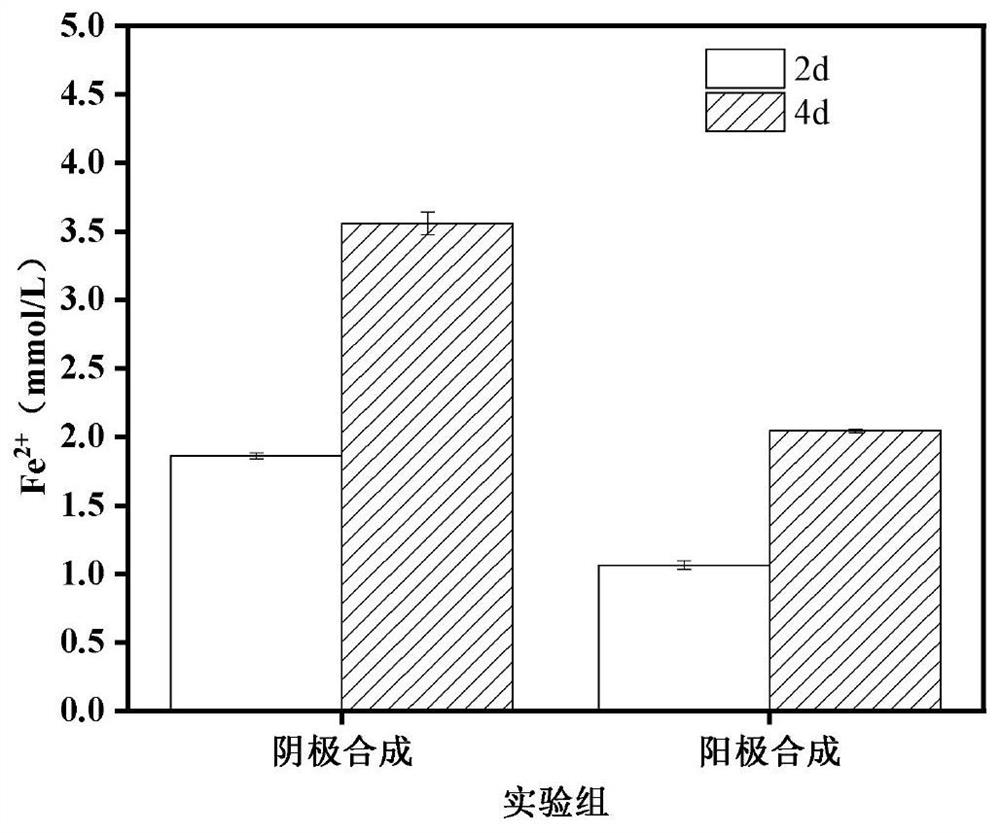

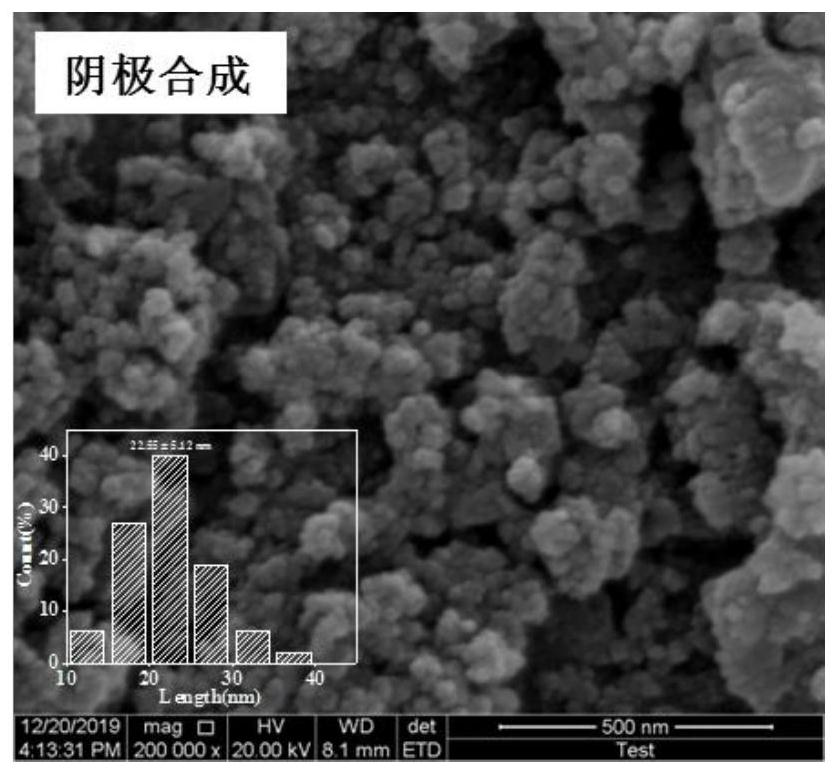

[0054] The present embodiment illustrates the influence of the two synthesis methods on the generation amount and properties of the nano-iron sulfide powder compared with the nano-iron sulfide powder prepared by the present invention and the in-situ synthesis of the traditional MFC anode:

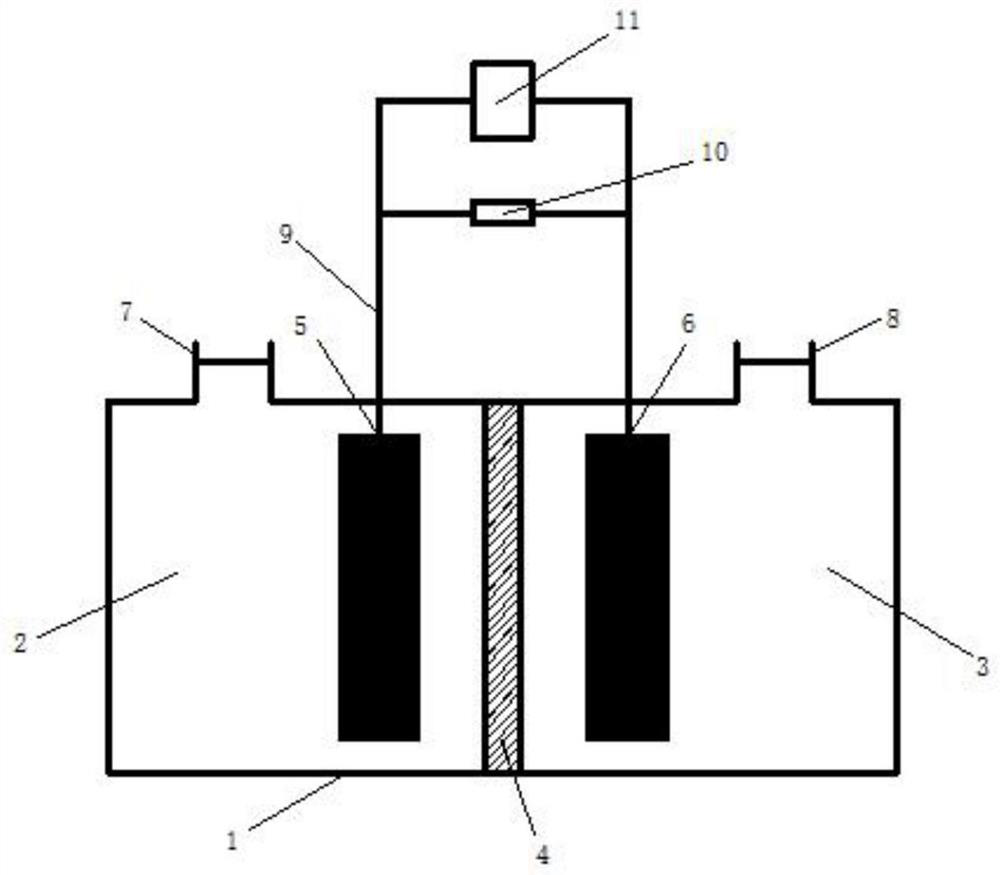

[0055] build as figure 1 In the dual-chamber MFC shown, a proton exchange membrane is arranged between the anode compartment and the cathode compartment, and an anode electrode and a cathode electrode are respectively arranged. The anode electrode and the cathode electrode are connected by an external circuit, and the electrode material is a carbon-based material.

[0056] (1) MFC anode uses anaerobic activated sludge (taken from Nanjing Jiangxinzhou Sewage Treatment Plant, hereinafter referred to as sludge) as the source of inoculated bacteria, the inoculation ratio is 1:2 (sludge: anolyte), and the anolyte is COD= 1000mg / L glucose simulated organic wastewater (0.31 g / LNH 4 Cl; 2.452g / LNa...

Embodiment 2

[0060] This example illustrates the effect of the nano-sulfur-iron hybrid biofilm electrode prepared by the present invention and the traditional MFC bio-cathode in the treatment of chromium-containing wastewater.

[0061] like figure 1 As shown in the construction of the biocathode MFC, the method for the domestication of the anode bioelectrode and the method for in-situ synthesis of nano-ferric sulfide at the cathode are the same as those described in Example 1, the only difference being that in step (1), the bacterial source inoculum is the lake bottom sediment, and the lake bottom sediment The volume ratio of the anolyte to the anolyte is 1:5, the anolyte is the actual organic waste water containing protein, oil and lignocellulose, the iron source used in the step (2) is ferric citrate, and the organic carbon source in the catholyte is sodium lactate and sodium pyruvate, the sulfur source is sodium sulfate, the buffer is 4-hydroxyethylpiperazine ethanesulfonic acid buffer,...

Embodiment 3

[0064] This example illustrates the effect of the nano-sulfur-iron hybrid biofilm electrode prepared by the present invention and the in-situ synthesis of nano-sulfur-iron hybrid at the MFC anode on strengthening the treatment of chromium-containing wastewater by MFC bio-cathode.

[0065] like figure 1 As shown in the construction of the biocathode MFC, the methods for the domestication of the anode bioelectrode, the in-situ synthesis of the anode and the synthesis of nano-ferric sulfide in the cathode are the same as those described in Example 1, the only difference being that the bacterial source inoculum in step (1) is electroplating. Sludge, the intermediate diaphragm of the MFC device is a bipolar membrane; in step (2), the organic carbon source in the catholyte is sodium acetate; the dechromization experiment of the cathode synthesis nano-iron sulfide experimental group is the same as that described in Example 2; The hybrid biofilm electrode obtained by in situ synthesis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com