Phosgenation reactor and method for preparing isocyanate monomer by using phosgenation reactor

A reactor and phosgenation technology, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, preparation of organic compounds, etc., can solve the problems of reduced yield, internal leakage blockage, high overall energy consumption, etc. problems, to avoid incomplete amine reaction, reduce contact opportunities, and improve the quality of salt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

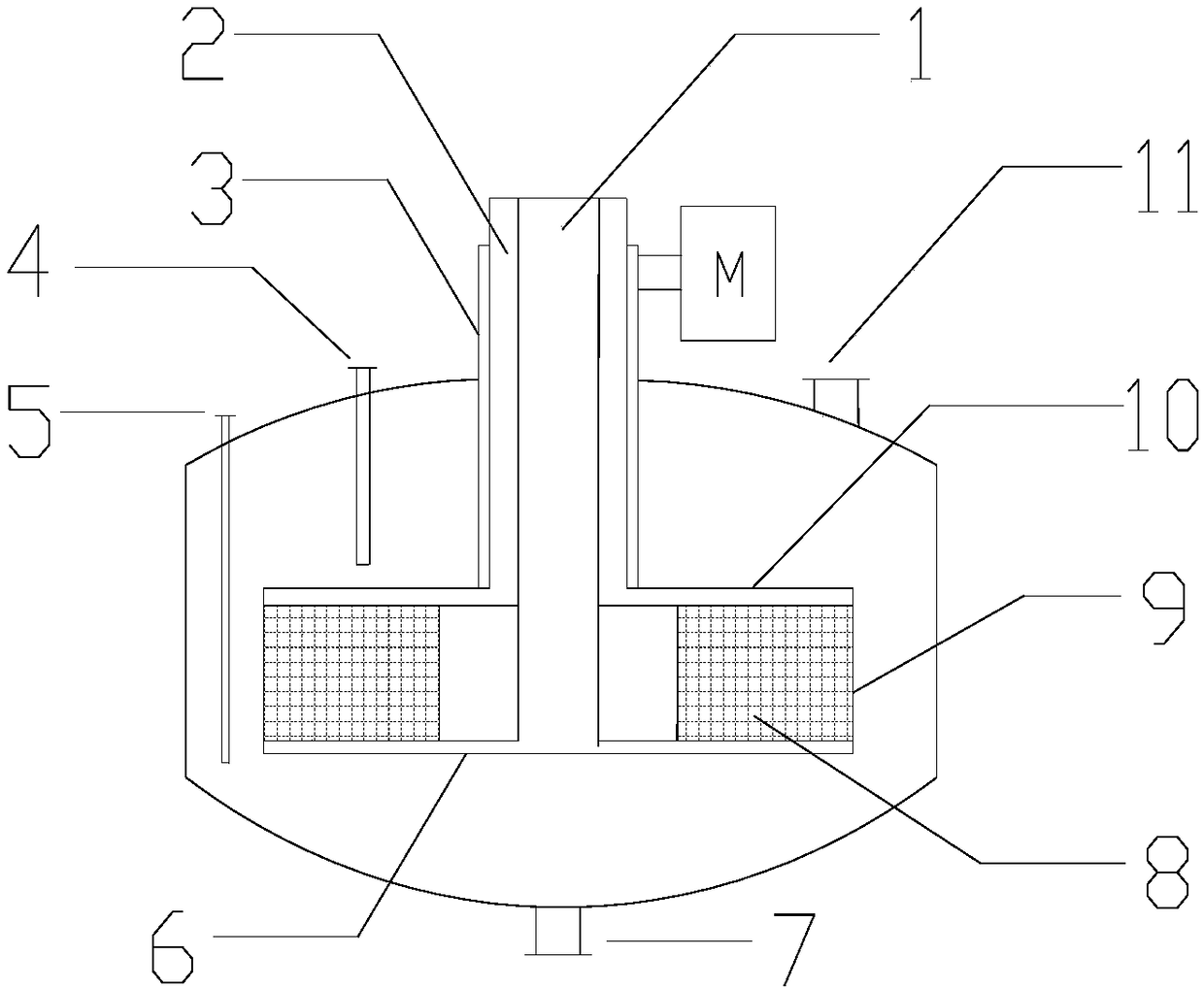

Embodiment 1

[0042] The volume of the phosgenation reactor is 800L, and the discharge device is vertical to the feed pipe. The ratio of the distance between the lower surface of the upper discharger and the upper surface of the lower discharger to the height of the reactor is 1:6, the upper and lower dischargers are hollow cylinder structures, and the lower surface of the upper discharger 10 and the upper surface of the lower discharge device 6 are evenly distributed circular outlet apertures, the opening ratio is 60% and 70% respectively, the discharge device diameter is 70% of the reactor diameter, the discharge device height and the discharge device diameter The ratio is 1:20, the distance ratio between the height of the packing block 8 in the rotating area and the lower surface of the upper discharger and the upper surface of the lower discharger is 1:1, and the filler is a wire mesh filler filled in a regular manner. The inner diameter of the outer feed pipe 2 is 1.3 times the inner d...

Embodiment 2

[0045] The volume of the phosgenation reactor is 800L, and the discharge device is vertical to the feed pipe. The ratio of the distance between the lower surface of the upper discharger and the upper surface of the lower discharger to the height of the reactor is 1:7, the upper and lower dischargers are hollow cylinder structures, and the lower surface of the upper discharger 10 and the upper surface of the lower discharge device 6 is uniformly distributed with diamond-shaped outlet apertures, the opening ratio is 70% and 55% respectively, the diameter of the discharge device is 80% of the diameter of the reactor, and the ratio of the height of the discharge device to the diameter of the discharge device The ratio of the height of the packing block 8 in the rotating area to the lower surface of the upper discharger and the upper surface of the lower discharger is 3:4, and the packing is a plate corrugated net packing filled in a regular manner. The inner diameter of the feed t...

Embodiment 3

[0048] The volume of the phosgenation reactor is 800L, and the discharge device is vertical to the feed pipe. The ratio of the distance between the lower surface of the upper discharger and the upper surface of the lower discharger to the height of the reactor is 1:8, the upper and lower dischargers are hollow cylinder structures, and the lower surface of the upper discharger 10 And the upper surface of the lower discharge device 6 evenly distributes triangular outlet small holes, the opening ratio is 65%, the discharge device diameter is 50% of the reactor diameter, and the ratio of the discharge device height to the discharge device diameter is 1: 40. The ratio of the height of the packing block 8 in the rotating area to the distance between the lower surface of the upper discharger and the upper surface of the lower discharger is 1:2. The filler is a plate corrugated mesh filler filled in a regular way, and the outer feed pipe The internal diameter of 2 is 1.5 times of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com