Preparation method and application of potassium-doped carbon nitride photocatalyst

A carbon nitride photocatalyst technology, applied in the field of catalysis, can solve the problems of limiting carbon nitride photocatalytic activity, short life of photogenerated carriers, high recombination rate, etc., to improve photocatalytic activity, increase specific surface area, and increase activity site effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

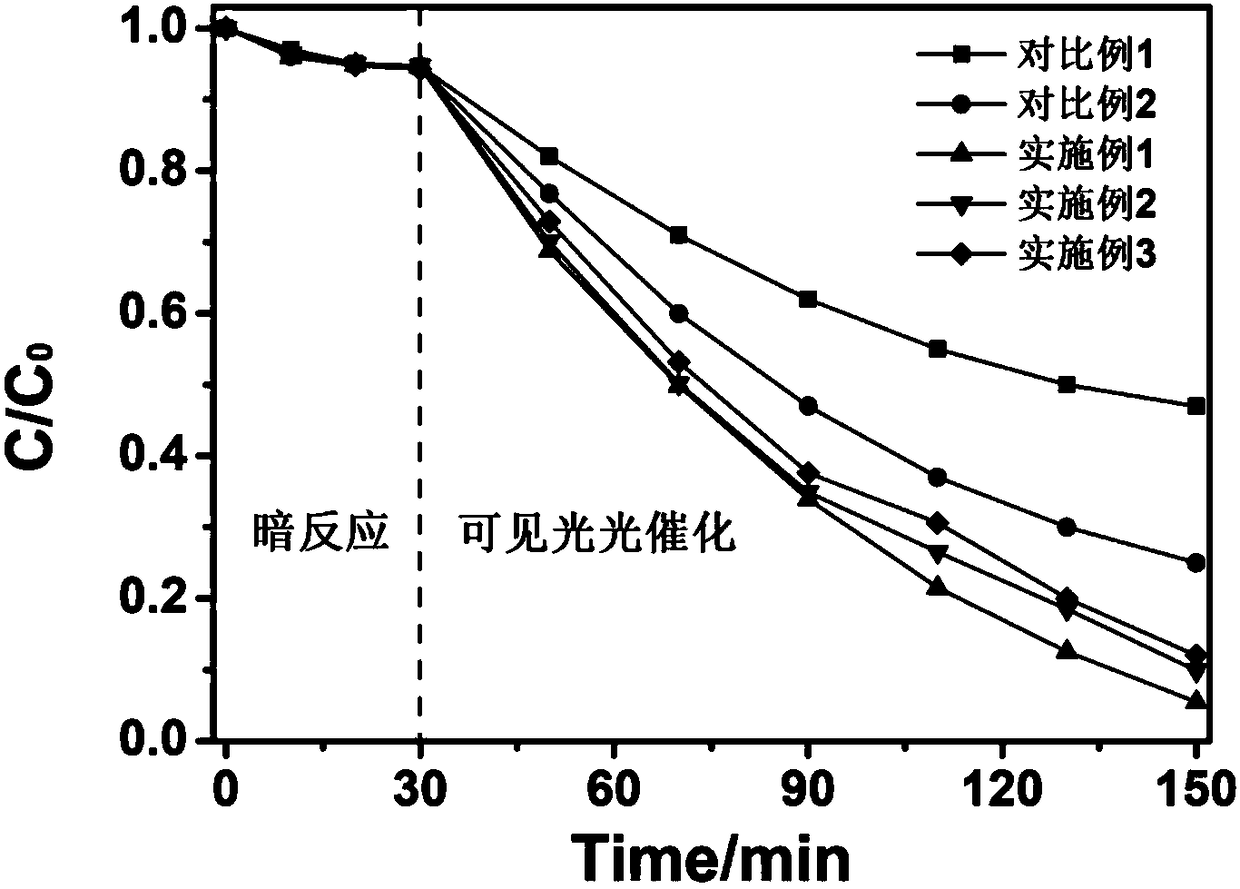

Embodiment 1

[0021] Mix 2g of ammonium chloride and 10g of dicyandiamide, then add 0.05g of potassium nitrate, mix evenly, and then place it in a muffle furnace for calcination. , cooled naturally to room temperature to obtain the potassium-doped carbon nitride photocatalyst.

Embodiment 2

[0023] Take 5g of ammonium chloride, 10g of dicyandiamide, and 0.1g of potassium nitrate, mix them uniformly, place them in a muffle furnace for calcination, and heat up at a rate of 5°C / min. After rising to 600°C, keep the temperature for 4 hours, and then cool naturally to room temperature , to obtain the potassium-doped carbon nitride photocatalyst.

Embodiment 3

[0025] Take 5g of ammonium chloride, 10g of dicyandiamide, and 0.15g of potassium nitrate, mix them uniformly, place them in a muffle furnace for calcination, and heat up at a rate of 3°C / min. After rising to 550°C, keep warm for 5 hours, and then cool naturally to room temperature , to obtain the potassium-doped carbon nitride photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com