Active positioning mechanism for position changing machine

A positioning mechanism and positioner technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inability to achieve pneumatic chuck rotation, achieve simple structure, long service life, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

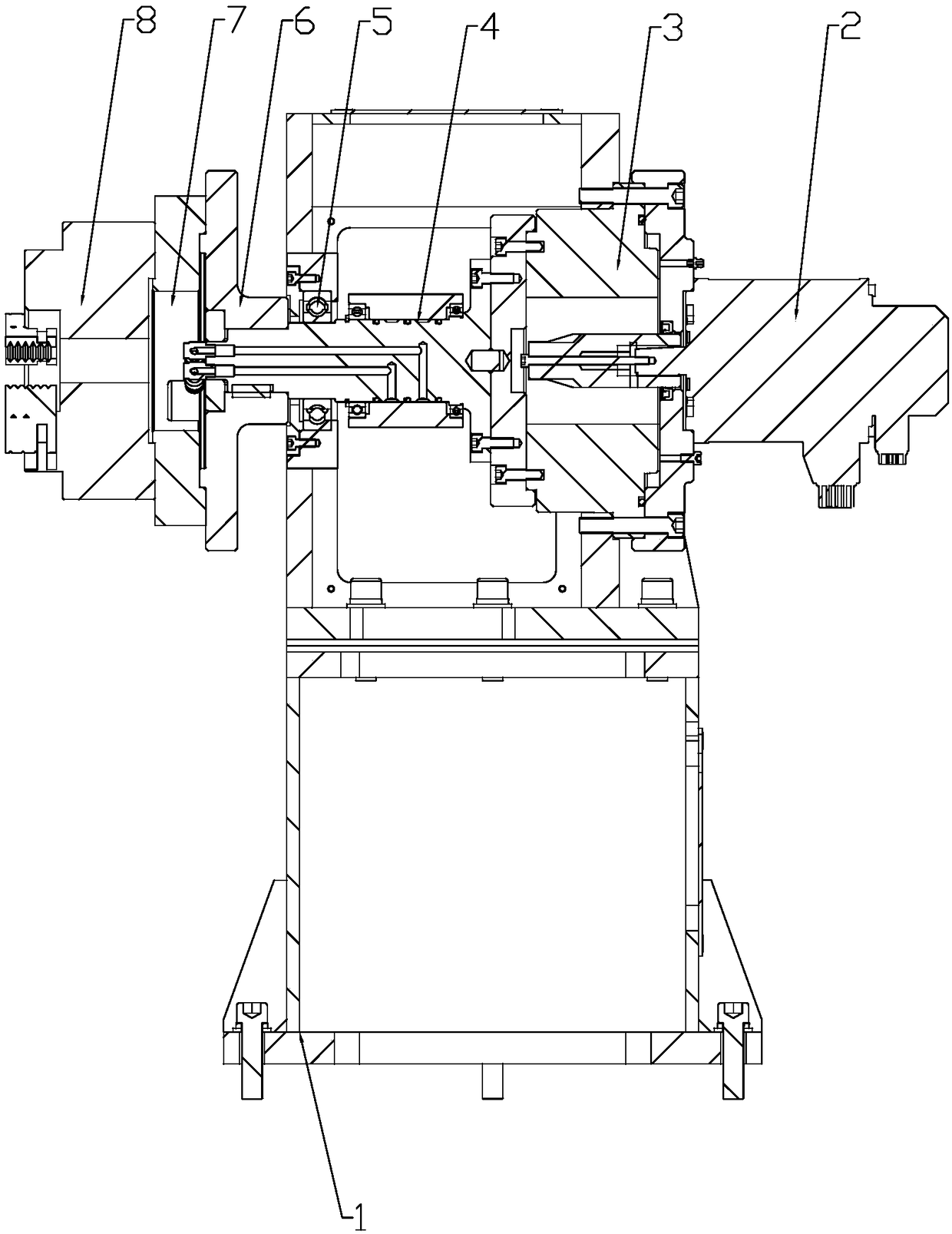

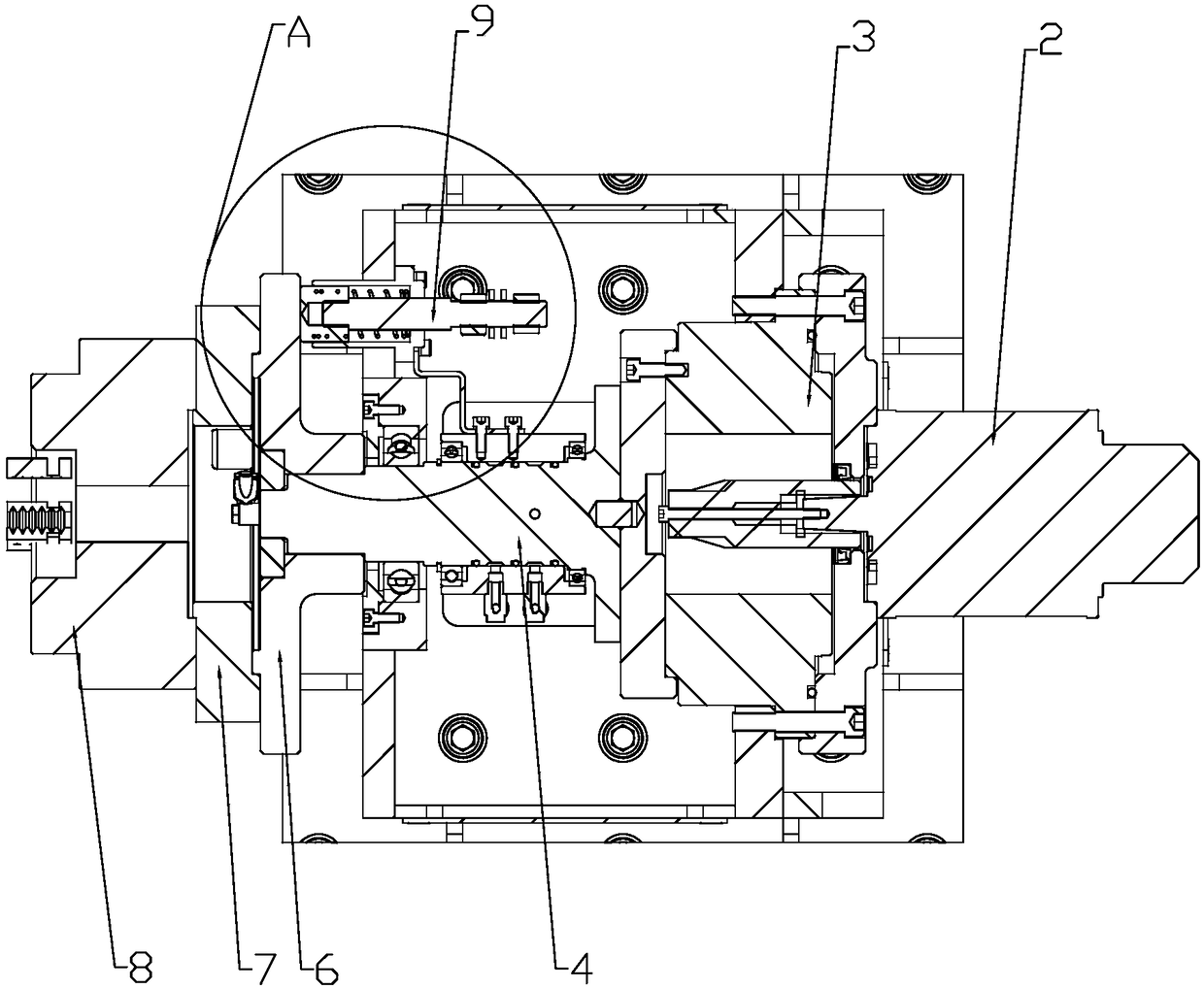

[0017] Such as Figure 1~2 As shown, the present invention mainly includes a main frame 1, a servo motor 2, a reducer 3, a two-way rotating mechanism 4, a turntable 6, a transition disk 7, a pneumatic chuck 8 and a conductive mechanism 9.

[0018] One side of the main frame 1 fixes the servo motor 2, the output end of the servo motor 2 is connected to the reducer 3, the output end of the reducer 3 is connected to the two-way rotating mechanism 4, and the two-way rotating mechanism 4 is connected in the main frame 1 through the bearing 5.

[0019] The front end of the two-way rotating mechanism 4 protrudes from the main frame 1 and is connected to the turntable 6 , the front end of the turntable 6 is connected to the transition disc 7 , and the front end of the transition disc 7 is connected to the pneumatic chuck 8 .

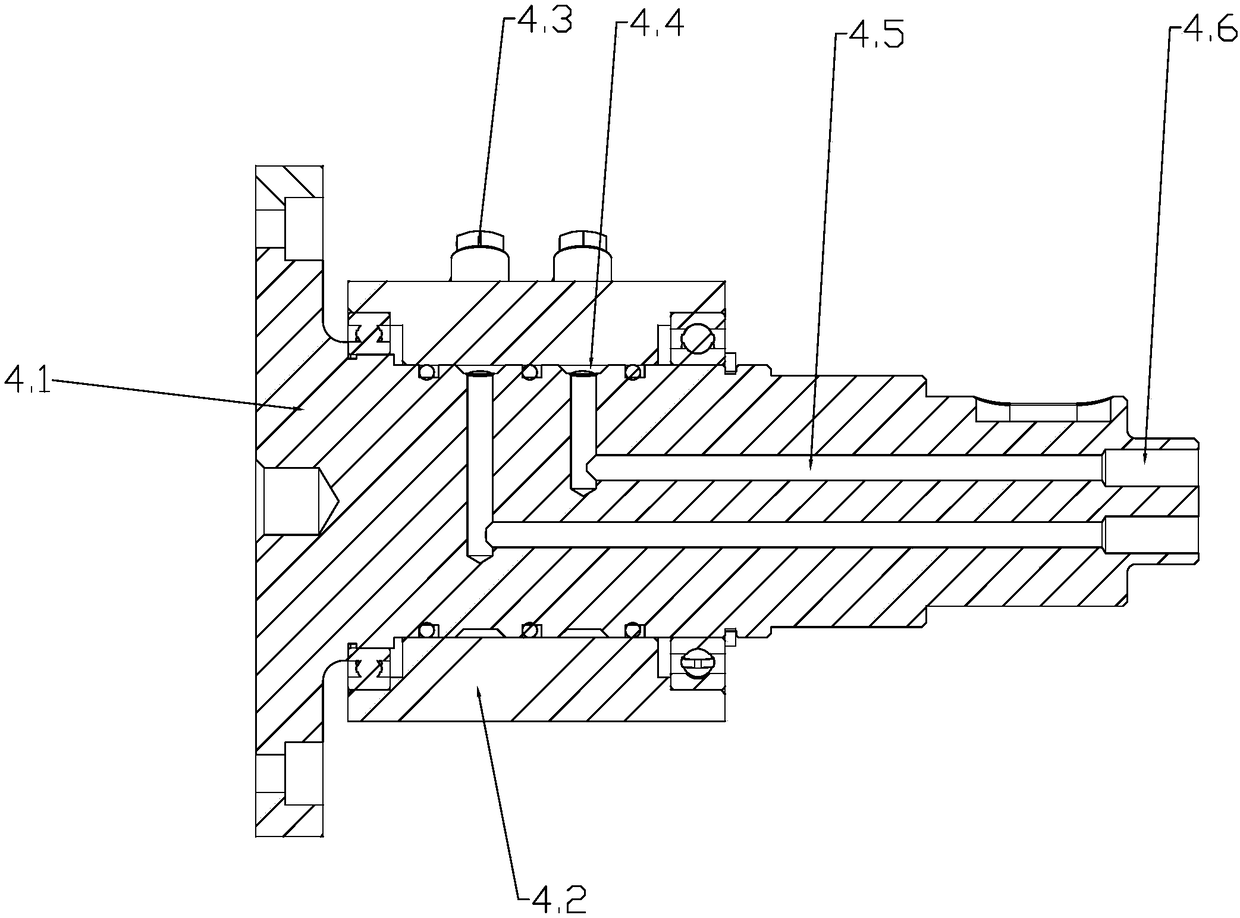

[0020] Such as image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com