Treatment method for phenolic ammonia wastewater produced by coal pyrolysis

A wastewater treatment and coal pyrolysis technology, which is applied in biological water/sewage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of high cost of extraction and dephenolization, achieve cost reduction, increase biochemical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

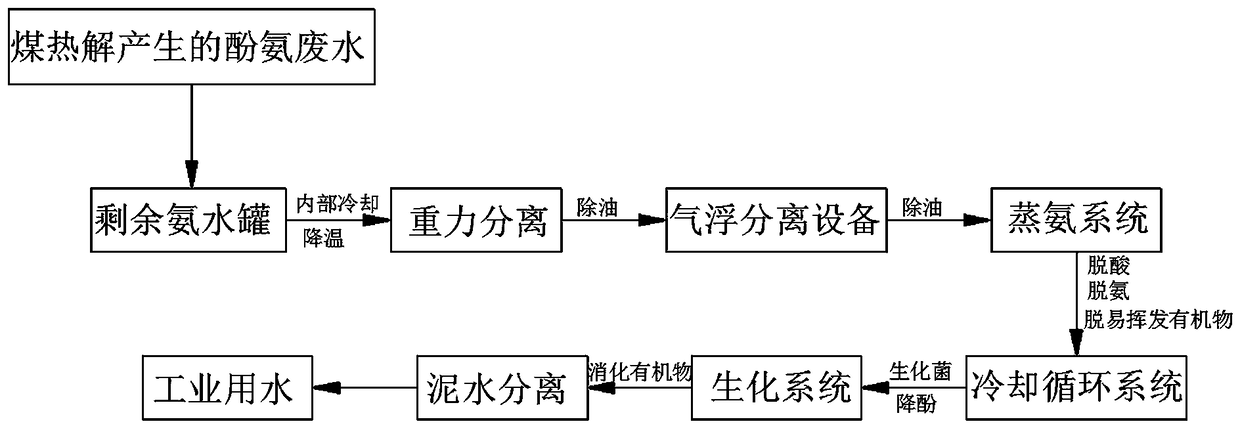

[0025] see figure 1 , the phenolic ammonia wastewater produced by coal pyrolysis overflows from the ammonia water tank to the remaining ammonia water tank, and a cooling device is installed in the remaining ammonia water tank to cool the remaining ammonia water through internal cooling, and the temperature of the remaining ammonia water drops from about 80°C to below 40°C , the solubility of phenolic substances in water decreased significantly, and the solubility of some heavy oils and light oils in phenolic ammonia wastewater decreased in water. Among them, most of them were phenolic oils. These oils were separated from phenolic ammonia wastewater and separated by gravity. The oil is separated to complete the primary pretreatment of phenolic ammonia wastewater; the phenolic ammonia wastewater pretreated by cooling and degreasing is passed through the air flotation pretreatment equipment, so that small oil droplets float up under the drive of air bubbles, gather on the liquid s...

Embodiment 2

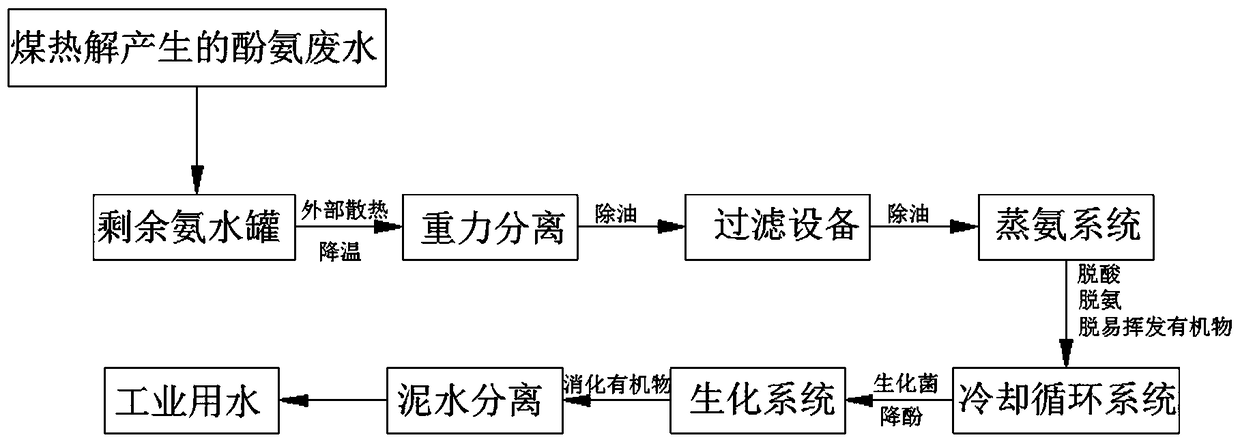

[0027] see figure 2 , the phenolic ammonia wastewater overflows from the ammonia water tank to the remaining ammonia water tank, the remaining ammonia water tank is set appropriately larger, and the heat sink is installed outside the tank body, so that the remaining ammonia water can be cooled naturally through external heat dissipation, and the temperature of the ammonia water drops from about 80°C to below 50°C , the solubility of phenolic substances in water decreased significantly, and the solubility of some heavy oils and light oils in phenolic ammonia wastewater decreased in water. Among them, most of them were phenolic oils. These oils were separated from phenolic ammonia wastewater and separated by gravity. The oil is separated out to complete the primary pretreatment of phenolic ammonia wastewater; the phenolic ammonia wastewater pretreated by cooling and degreasing passes through the hydrophilic and oleophobic filter equipment, and small oil droplets gather on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com