Ignition agent composition with reliable ignition performances and preparation method thereof

A technology of ignition performance and composition, which is applied in the direction of explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of high content, inability to play a good release effect, and low sensitivity of aluminum powder, so as to improve ignition performance and enhance Ignition performance, uniform ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

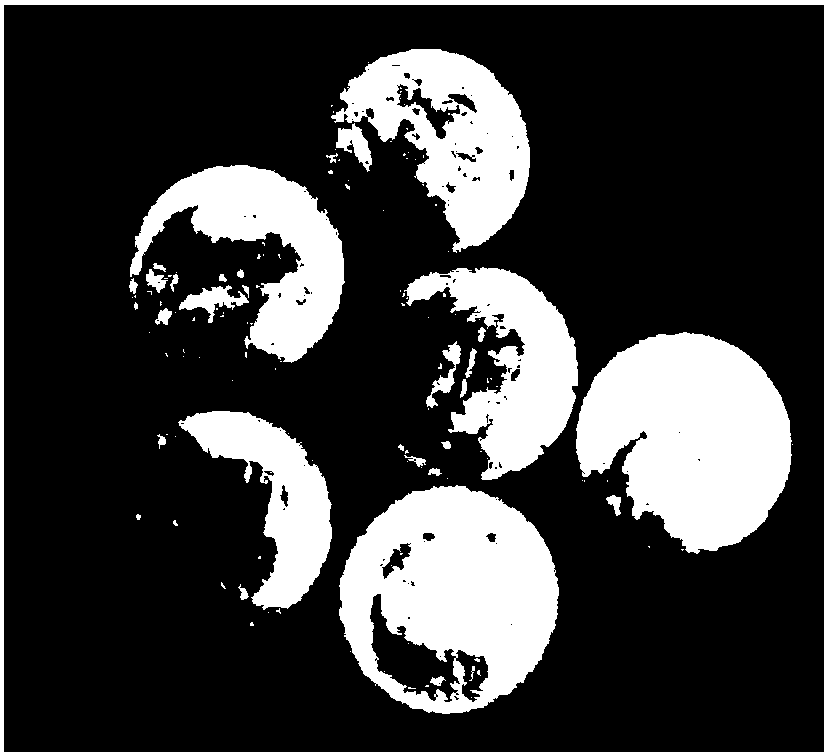

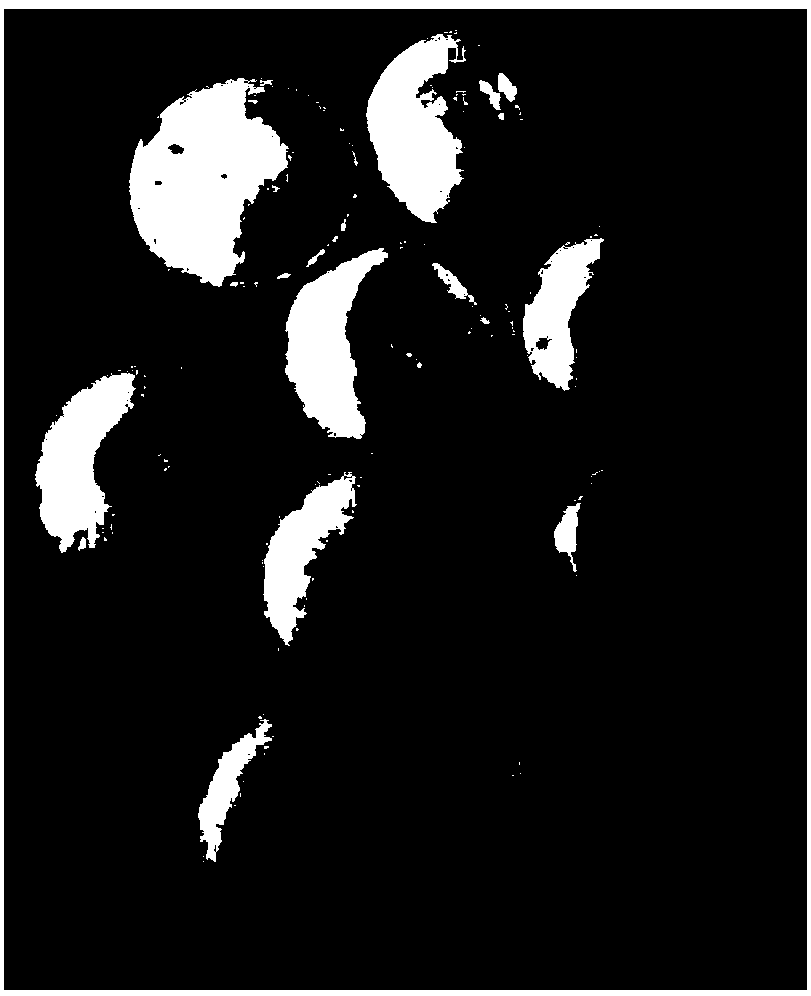

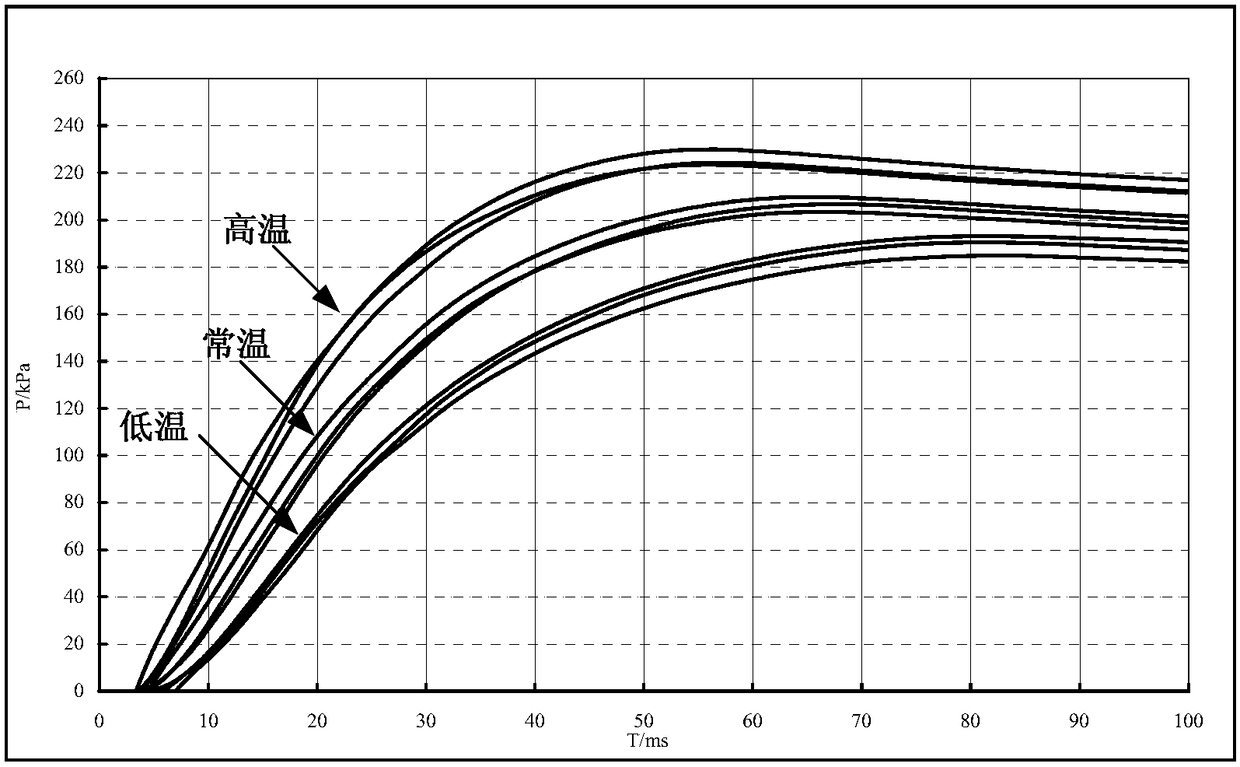

Image

Examples

preparation example Construction

[0069] The present invention adopts the mode of wet granulation to prepare ignition agent composition, and specific preparation method comprises the following steps:

[0070] (1), the first material is obtained after mixing strontium nitrate, 5-aminotetrazole, potassium nitrate, mica powder, aluminum oxide, graphite and boron nitride; it can be mixed in a mixing device to obtain the first material, mixed The time is ≤20min; the mixing equipment can use a ribbon mixer.

[0071] (2), add water to the first material and carry out wet mixing to obtain the second material, wherein the amount of water added is 3% to 15% of the total mass of the first material; the wet mixing time is 2min to 15min; wet mixing equipment For kneader or mixer.

[0072] (3), passing the second material through a 10-40 mesh screen to obtain the third material;

[0073] (4), the third material is dried until the water content is less than 0.5% of the total mass of the third material, and the fourth mater...

Embodiment 1

[0098] The ignition agent composition comprises the following components in mass percent content:

[0099]

[0100] After these components are weighed, they are compressed into discs with a diameter of 6.4 mm and a thickness of 2.7 to 3.1 mm by wet granulation and a rotary tablet press. The specific preparation method is: mix strontium nitrate, 5-aminotetrazole (5-AT), potassium nitrate, mica powder, aluminum oxide, graphite and boron nitride through a ribbon mixer to obtain the first material; Add 10% (mass percentage content) of distilled water to the first material and carry out wet kneading for 12 minutes to obtain the second material, pass the second material through a 10-mesh screen to obtain the third material; dry the third material to a water content of It is less than 0.5% of the total mass of the third material, and the fourth material is obtained through a 20-mesh screen again; the fourth material is formed by a rotary tablet press to obtain a circular sheet str...

Embodiment 2

[0106] The ignition agent composition comprises the following components in mass percent content:

[0107]

[0108] After these components are weighed, they are compressed into discs with a diameter of 6.4 mm and a thickness of 2.7 to 3.1 mm by wet granulation and a rotary tablet press. The specific preparation method is: mix strontium nitrate, 5-aminotetrazole (5-AT), potassium nitrate, mica powder, aluminum oxide, graphite and boron nitride through a ribbon mixer to obtain the first material; Add 6% (mass percentage content) of distilled water to the first material and carry out wet kneading for 10 minutes to obtain the second material, pass the second material through a 10-mesh screen to obtain the third material; dry the third material to a water content of It is less than 0.5% of the total mass of the third material, and the fourth material is obtained by passing through a 10-mesh sieve again; the fourth material is formed by a rotary tablet press to obtain a circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com