Method for enhancing crystallinity and mechanical performance of polymer, device and obtained product

A polymer and mechanical technology, applied in the field of polymer materials, can solve the problems of high heating energy consumption, complex process equipment, pollution, etc., and achieve the effect of simple process, reduced solvent consumption, and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

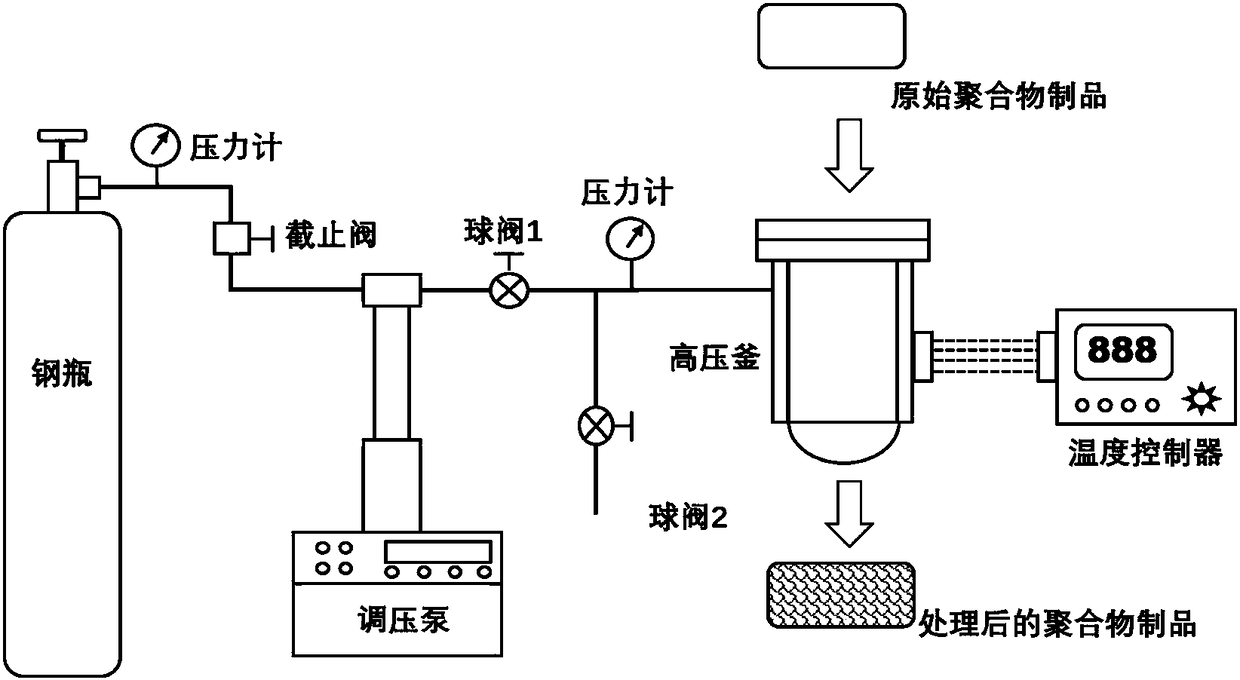

Method used

Image

Examples

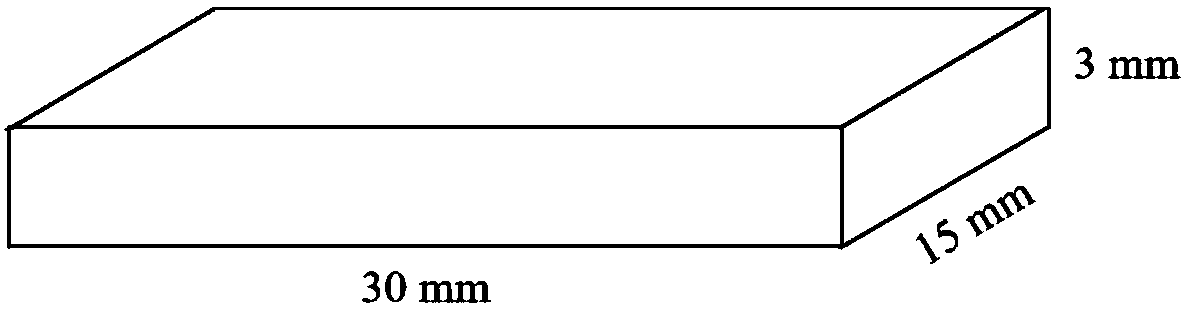

Embodiment 1

[0039] The raw material is polylactic acid particles with the brand name 4032D provided by Natureworks. The specific treatment process is as follows: Step 1, remove the moisture in the raw material by vacuum drying, the drying temperature is 70°C, and the drying time is 4 hours. In the 2nd step, on the injection molding machine, the polylactic acid particles processed into elongated polylactic acid products (such as figure 2 ), the melt temperature, mold temperature, injection speed, injection pressure, holding pressure, and holding time are 175°C, 30°C, and 50cm 3 / s, 100MPa, 60MPa and 3s. Step 3: After the temperature of the autoclave is adjusted to 25°C, place the injection-molded polylactic acid product in the autoclave, then close the autoclave, and ensure that the autoclave is well sealed. In step 4, a carbon dioxide fluid medium with a pressure of 6.9 MPa is introduced into the autoclave. Step 5: After the carbon dioxide pressure in the autoclave is stable, use a te...

Embodiment 2

[0043] The raw material is polycarbonate pellets of Lexan 141R provided by Saudi Basic Innovative Plastics Company. The specific treatment process is as follows: Step 1, remove the moisture in the raw material by vacuum drying, the drying temperature is 110°C, and the drying time is 6 hours. In the 2nd step, on the injection molding machine, the high-density polycarbonate pellets processed into long polycarbonate products (such as figure 2 ), the melt temperature, mold temperature, injection speed, injection pressure, holding pressure, and holding time are 260°C, 50°C, and 40cm 3 / s, 100MPa, 60MPa and 4s. Step 3: After the temperature of the autoclave is adjusted to 25°C, place the injection-molded polycarbonate product in the autoclave, then close the autoclave, and ensure that the autoclave is well sealed. In step 4, a carbon dioxide fluid medium with a pressure of 35 MPa is introduced into the autoclave. Step 5: After the carbon dioxide pressure in the autoclave is stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com