Fluorescent carbon quantum dot with magnolia alba leaf blades as carbon source and preparation method of fluorescent carbon quantum dot

A carbon quantum dot and fluorescence quantum yield technology, which is applied in the preparation of fluorescent carbon quantum dots and the field of fluorescent carbon quantum dots, can solve the problems of few fluorescent active sites and low yield of carbon quantum dots, and achieve good biocompatibility. High performance, strong fluorescence, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of novel fluorescent carbon quantum dots using white orchid leaves as a carbon source, comprising the following steps:

[0024] (1) Dissolve 0.50 g of white orchid leaf powder in 30 mL of deionized water to a concentration of 0.017 g / mL, ultrasonically oscillate for 20 min, and react at 180 °C for 4 h by hydrothermal method to obtain fluorescent carbon quantum dot solution;

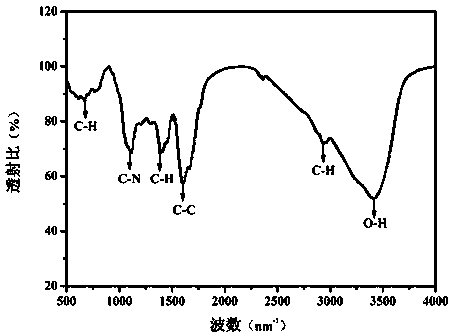

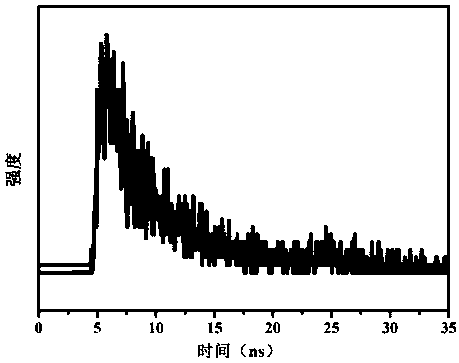

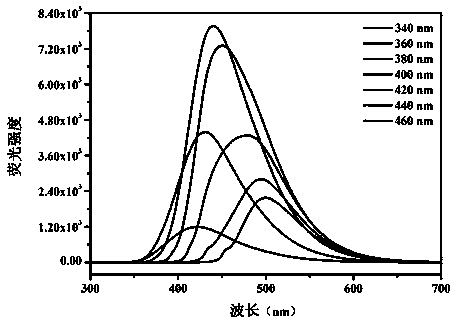

[0025] (2) Ultracentrifuge the fluorescent carbon quantum dot solution at 6000 r / min for 10 min, then filter it with an aqueous syringe filter, and take the supernatant to obtain the fluorescent carbon quantum dot solution. Using single-photon technology to measure the fluorescence retention time of carbon quantum dots, the average fluorescence lifetime is calculated to be 4.38 ns, and quinine sulfate (Q Y =54.0%) as a reference, the fluorescent carbon quantum dot solution with a fluorescence quantum yield of 8.3%.

Embodiment 2

[0027] A preparation method of novel fluorescent carbon quantum dots using white orchid leaves as a carbon source, comprising the following steps:

[0028] (1) Dissolve 1.50 g of white orchid leaf powder in 30 mL of deionized water to a concentration of 0.050 g / mL, ultrasonically oscillate for 30 min, and react at 200 °C for 16 h by hydrothermal method to obtain fluorescent carbon quantum dot solution;

[0029] (2) The fluorescent carbon quantum dot solution was ultracentrifuged at 8000 r / min for 30 min, and then filtered with a 0.22 μm aqueous syringe filter. Using single-photon technology to measure the fluorescence retention time of carbon quantum dots, the average fluorescence lifetime is calculated to be 4.38 ns, and quinine sulfate (Q Y =54.0%) as a reference, the fluorescent carbon quantum dot solution with a fluorescence quantum yield of 13.8%.

Embodiment 3

[0031] A preparation method of novel fluorescent carbon quantum dots using white orchid leaves as a carbon source, comprising the following steps:

[0032] (1) Dissolve 2.00 g of white orchid leaf powder in 30 mL of deionized water to a concentration of 0.067 g / mL, ultrasonically oscillate for 30 min, and react at 220 °C for 24 h by hydrothermal method to obtain fluorescent carbon quantum dot solution;

[0033] (2) The fluorescent carbon quantum dot solution was ultracentrifuged at 16000 r / min for 30 min, and then filtered with a 0.22 μm aqueous syringe filter. The fluorescence retention time of carbon quantum dots was measured by single-photon technology, and the average fluorescence lifetime was 4.38 ns. Y =54.0%) as a reference, the fluorescent carbon quantum dot solution with a fluorescence quantum yield of 11.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com