Industrial energy-saving boiler system

An industrial boiler technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of wasting water resources, high labor intensity of workers, and long heating time, so as to improve the utilization rate of heat, Effect of shortening heating time and saving fuel energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

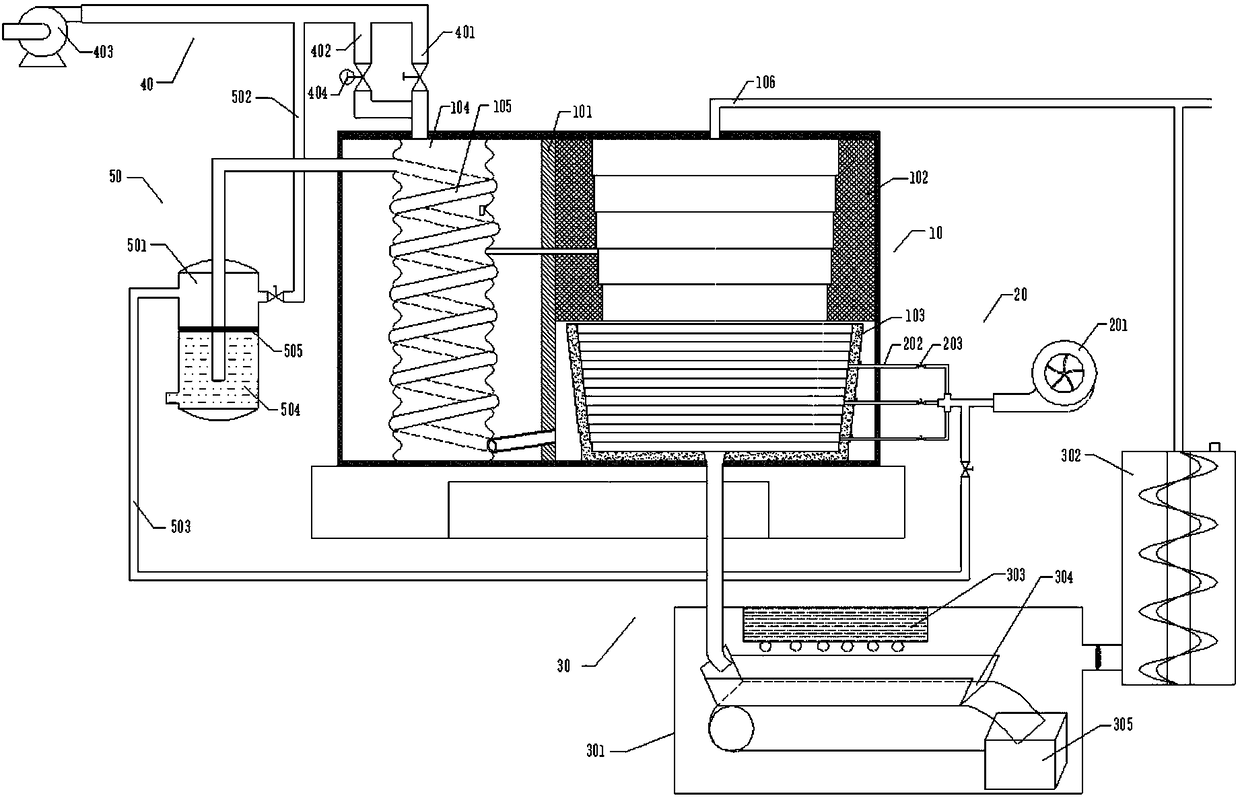

[0020] Such as figure 1 As shown, an industrial energy-saving boiler system includes a boiler main body 10, an air supply part 20, a waste residue treatment part 30, a water supply part 40 and a dust removal part 50; body 103, water storage tank 104 and heat exchange tube 105, the partition plate 101 is set to divide the inner cavity of the boiler body 10 into left and right chambers, the heating pot body 102 and the furnace body 103 are arranged in one room, and the heating pot body 102 Furnace body 103 is arranged below, and water storage tank 104 and heat exchange pipe 105 are arranged in another room; heat, and the side of the heating pot 102 close to the partition 101 is set to communicate with the water storage tank 104 through the water inlet pipe, and the inner side wall of the furnace b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com