Monitoring management system for the safe operation of point inspection hoisting device

A technology for safe operation and lifting equipment, which is applied in the field of monitoring and management system for point inspection of safe operation of lifting equipment, can solve the problems of failure to carry out effective supervision, such as failure to go to the site for site inspection, unable to eliminate illegal operations, etc., to achieve Facilitate work assessment, reduce maintenance and overhaul costs, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

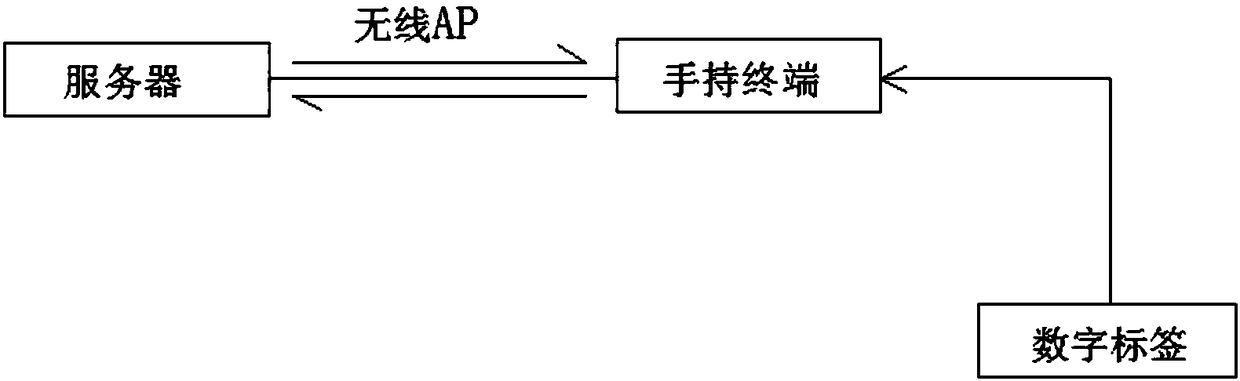

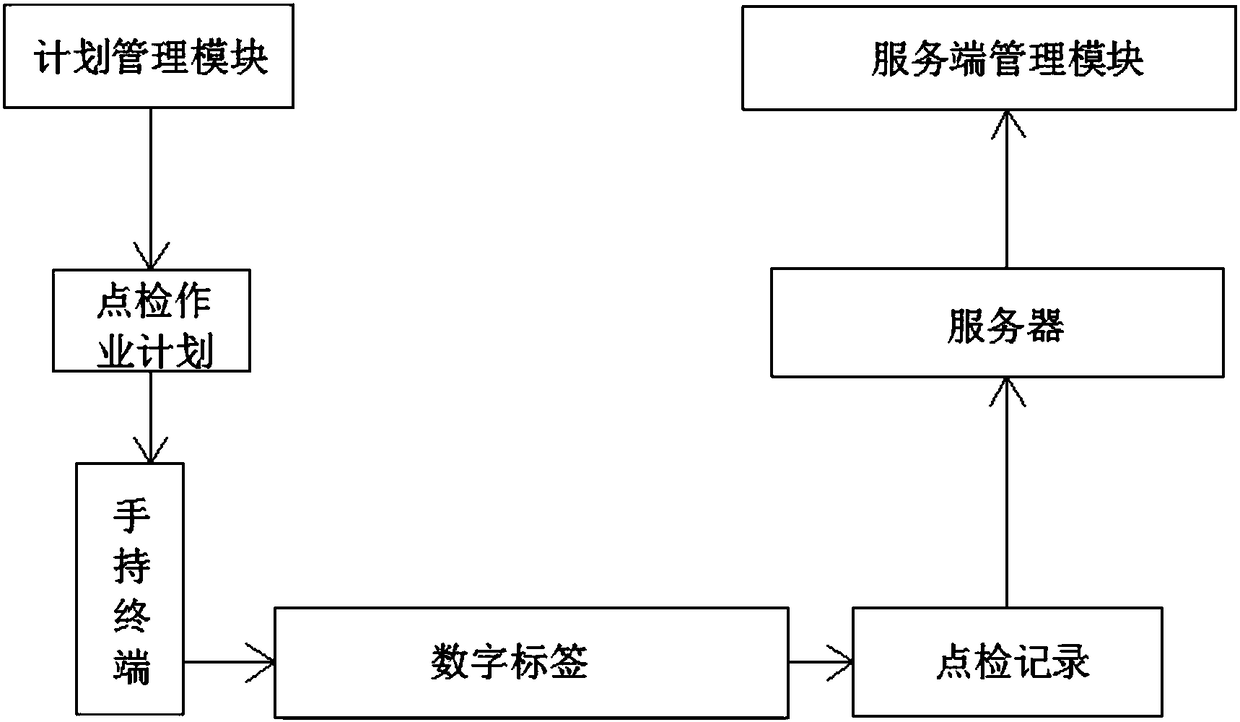

[0020] Such as Figure 1 to Figure 3 As shown, a monitoring and management system for spot inspection of safe operation of lifting equipment includes a server, a handheld terminal, and digital tags set on key nodes of the lifting equipment on the inspection route, and one digital tag corresponds to one lifting equipment. The hand-held terminal downloads the inspection operation plan of the equipment to be inspected from the server, and enters and uploads the equipment information corresponding to each digital label collected and processed during the inspection process to the server.

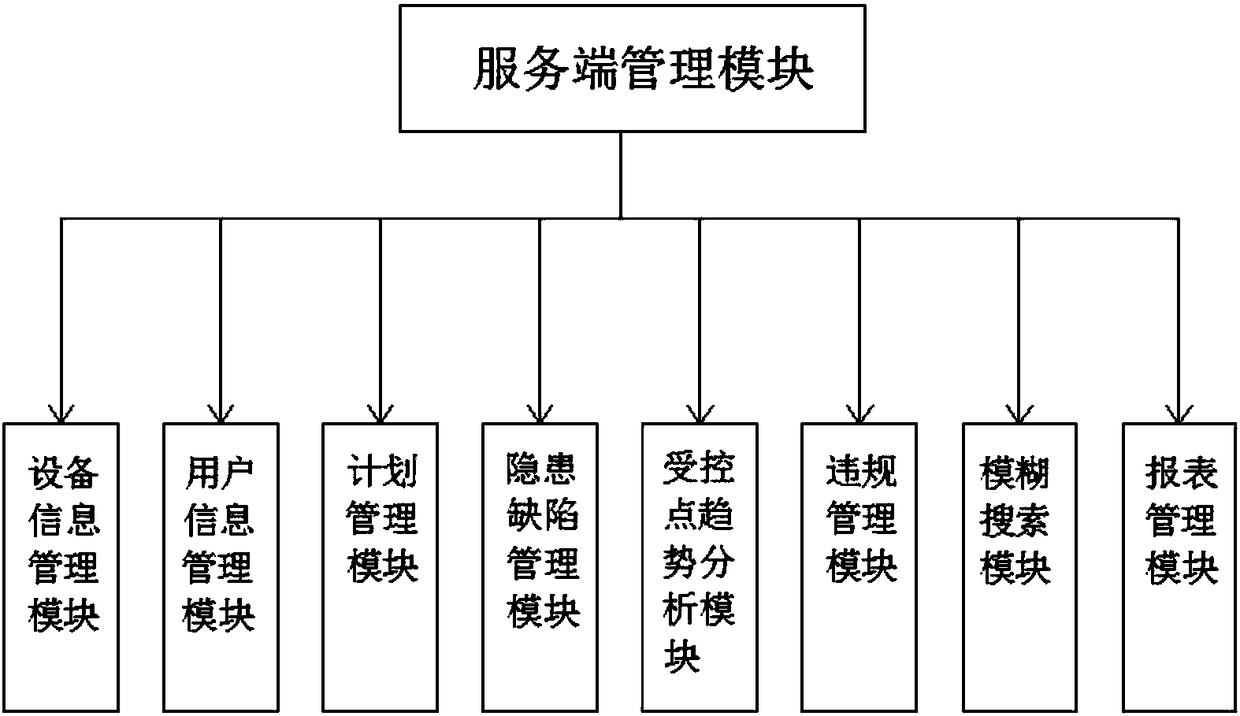

[0021] The server has a server management module.

[0022] The server management module includes: equipment information management module, user information ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com