Preparation method of lithium-deintercalation-state lithium ion battery positive electrode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low battery voltage, potential safety hazards, and large environmental pollution, and achieve long storage life, high specific energy and power The effect of high characteristics and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

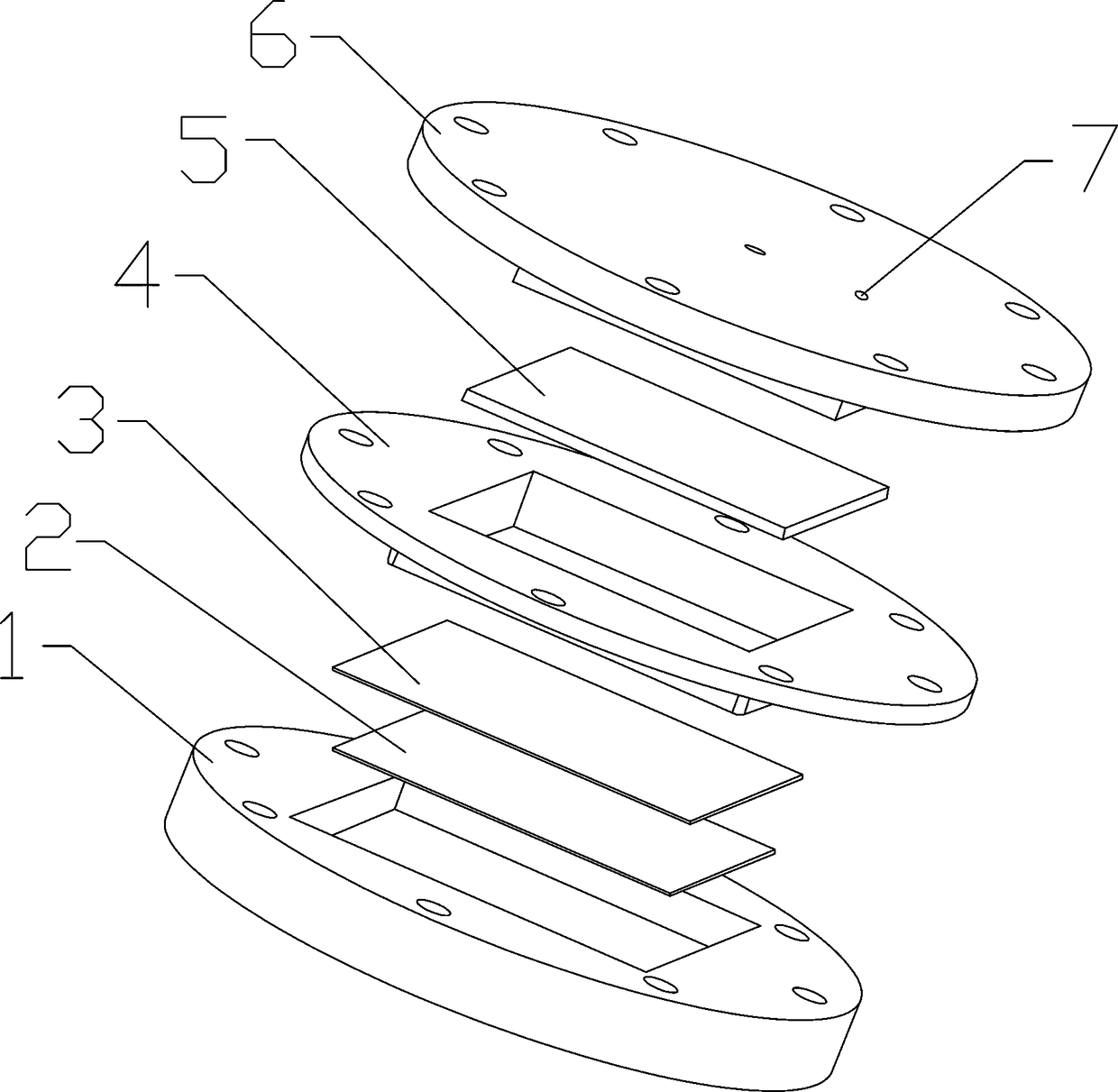

[0016] figure 1 Shown is a schematic diagram of the tooling of the formation battery, including a base plate 1, a cover plate 6, and a separator 4 arranged between the base plate 1 and the cover plate 6. The cover plate 6 is provided with a liquid injection port 7, and the base plate 1 is provided with a liquid injection port. cavity, and the liquid injection cavity is filled with electrolyte, and the negative electrode 2, separator 3 and positive electrode 5 of the lithium ion battery are placed in sequence.

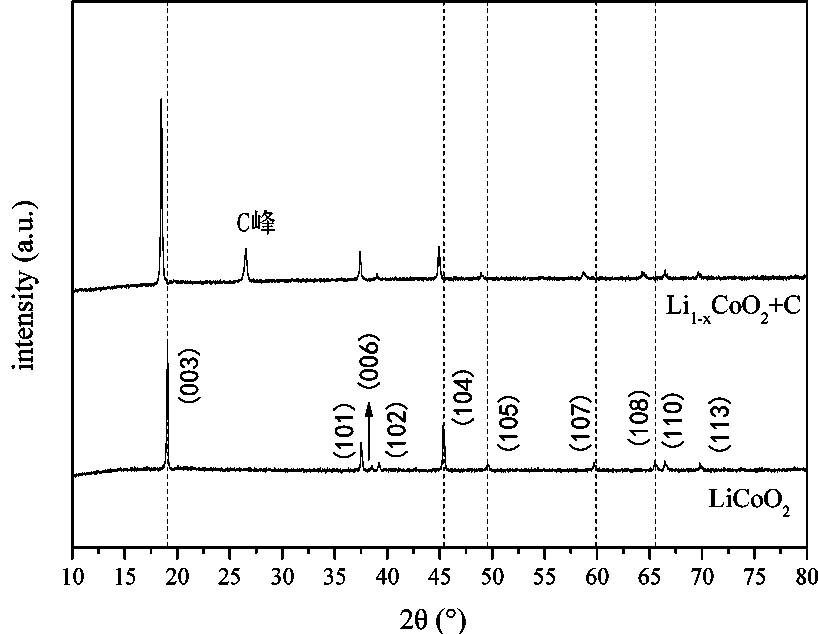

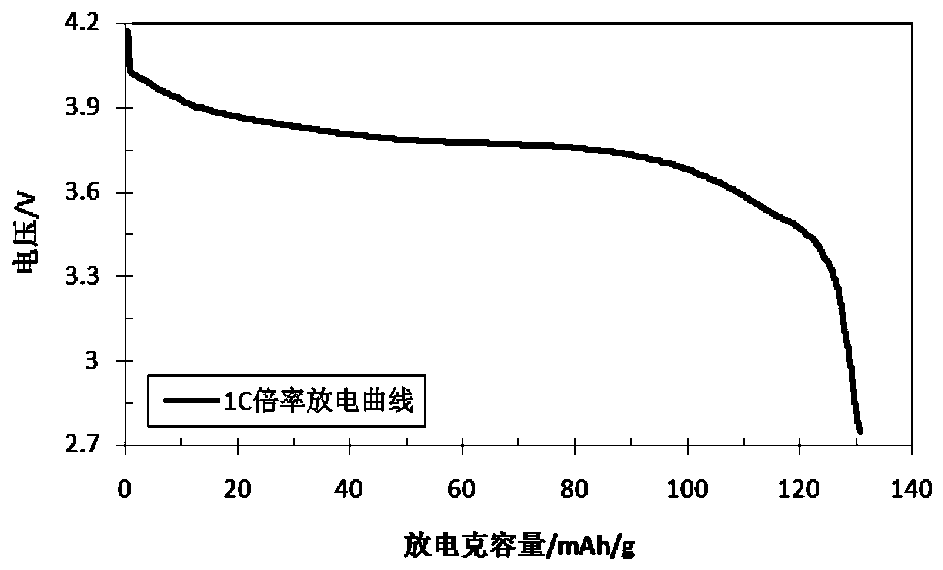

[0017] refer to figure 2 , image 3 As shown, the present invention discloses a preparation method of a lithium-ion battery cathode material in a delithiated state. First, a certain proportion of a commercial lithium-intercalated lithium-ion cathode material and a conductive agent is weighed, and after mixing and drying, an electrolyte is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com