Fault-tolerant control method and system for back-to-back converters of wind power generation system

A technology of back-to-back converters and wind power generation systems, applied in wind power generation, conversion of AC power input to AC power output, circuit devices, etc., can solve problems such as disasters, production process stoppage of converters, and converter failures , to achieve the effects of simple algorithm, reduced equipment investment, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

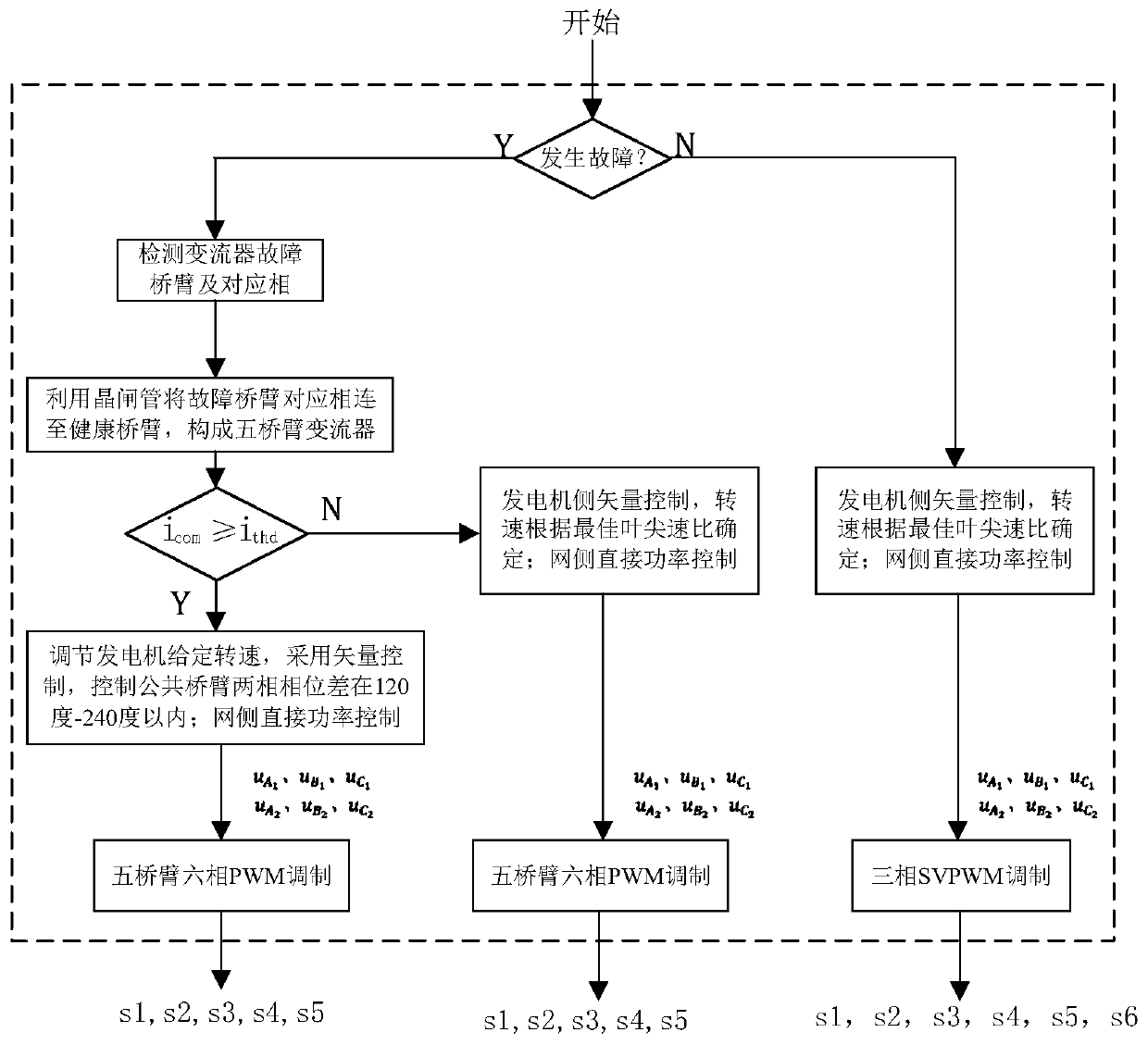

[0019] The present invention will be described below with reference to the accompanying drawings.

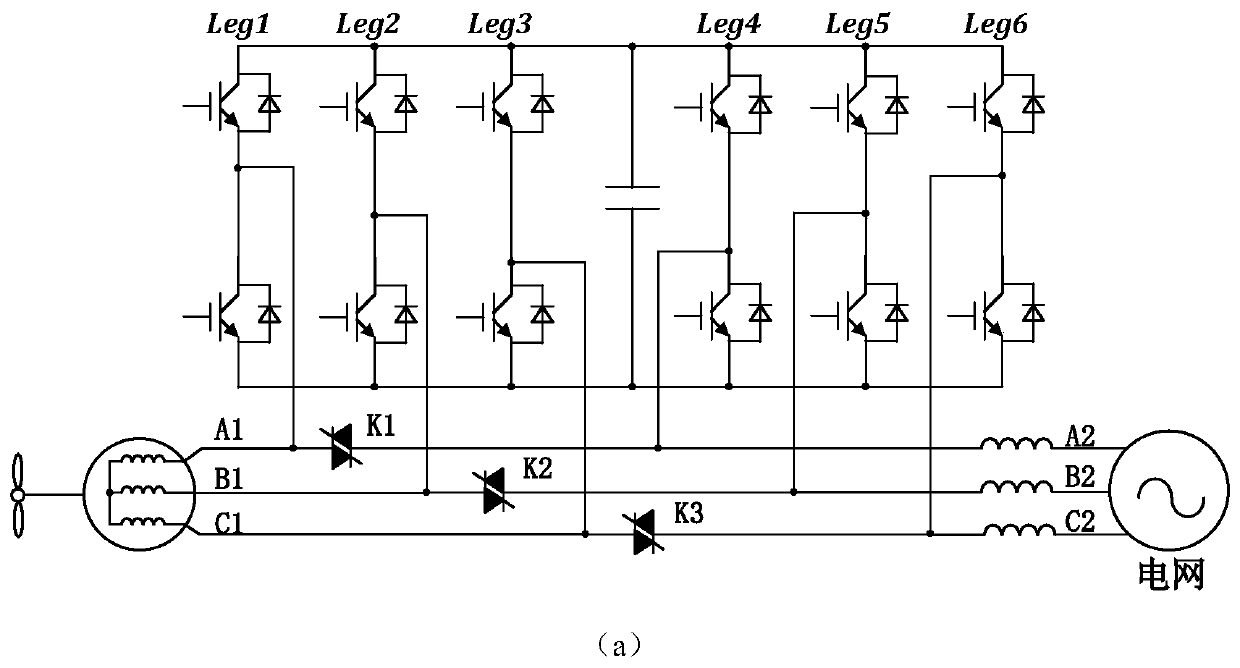

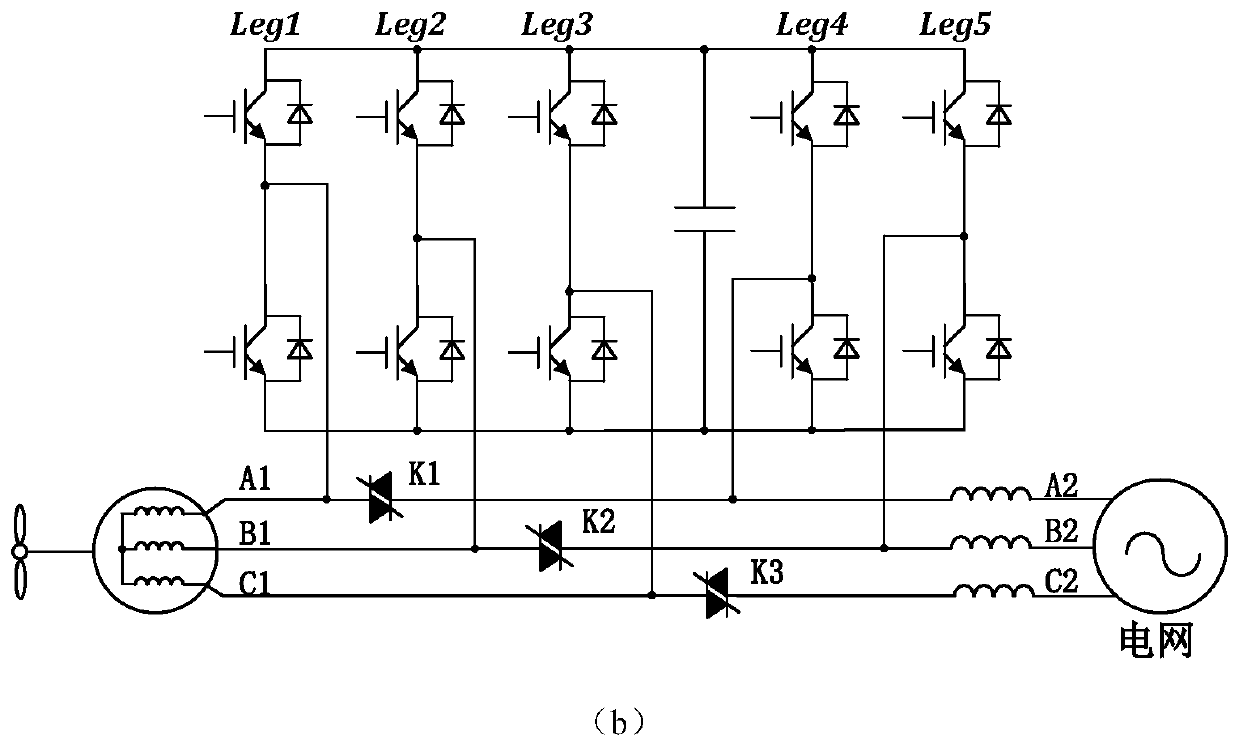

[0020] The system hardware structure of the embodiment of the present invention is as figure 2 As shown, the wind power generation system includes: a wind turbine, a back-to-back converter, a DC bus support capacitor group and three sets of bidirectional thyristors; the wind generator is an ordinary three-phase motor, and the back-to-back converter is a six-arm Two-level structure, the three-phase windings of the wind turbine are respectively connected to the three bridge arms of the converter, and the other three bridge arms of the converter are connected to the power grid; the DC bus support capacitor group is a series-parallel structure of multiple capacitors, To meet the requirements of DC bus voltage and output power; three sets of bidirectional thyristors are connected to the windings on the grid side and the motor side, while ensuring that only one set of triacs are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com