Stator-rotor structure for high-efficiency permanent-magnet hub motor

A technology for in-wheel motors, stators and rotors, which is applied in the shape/style/structure of magnetic circuits, motors, and rotating parts of magnetic circuits, etc., can solve the problems of shortening the service life of in-wheel motors, damage of power batteries and permanent magnets, and air-gap magnetic density waveforms. It can improve the back EMF waveform, reduce the eddy current loss and torque ripple, and reduce the leakage flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

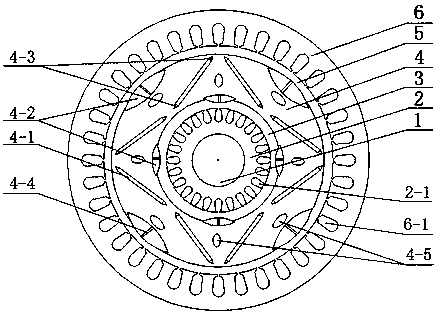

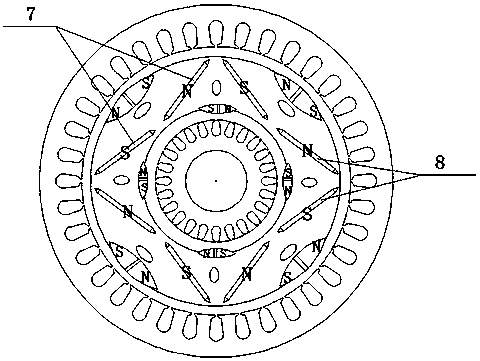

[0015] Such as figure 1 As shown, a high-efficiency permanent magnet hub motor stator-rotor structure includes a rotating shaft 1, an inner stator core 2, an inner air gap 3, a rotor core 4, an outer air gap 5, an outer stator core 6, and an inner stator slot 2-1. Main permanent magnet 4-1, auxiliary permanent magnet 4-2, magnetic isolation block 4-3, magnetic isolation strip 4-4, cooling hole 4-5, outer stator slot 6-1, etc.

[0016] The structure of the present invention is inner stator-rotor-outer stator from inside to outside. Both stator cores have their own windings and can work independently. The same rotor core 4 inner rotor is realized by controlling the on and off of the stator winding current. Freely switch between the drive modes of the outer rotor and the motor, when the motor needs to provide a high-speed, low-torque operating mode, the rotor core 4 and the inner stator core 2 form a high-speed inner rotor hub motor, and the magnetic circuit is a small V structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com