Gradient porous material

A technology of gradient porous and porous materials, applied in the field of porous materials, can solve the problems of poor bonding performance of porous materials at both ends of the interface, different chemical reactions at both ends of the interface, and large resistance, so as to be beneficial to bone regeneration and reduce the impact of the interface. , good effect of bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A gradient porous material, wherein the gradient of the porous material is graded, and is graded according to the pore size of the pores in the gradient porous material body. The porous material formed by larger pores, the pores of the gradient porous materials that constitute the gradient porous material are interconnected, and in this example, the interface area of two adjacent gradient porous materials is larger than that of two adjacent gradient porous materials. For hierarchical porous materials, the plane is used as the area of the plane of the interface.

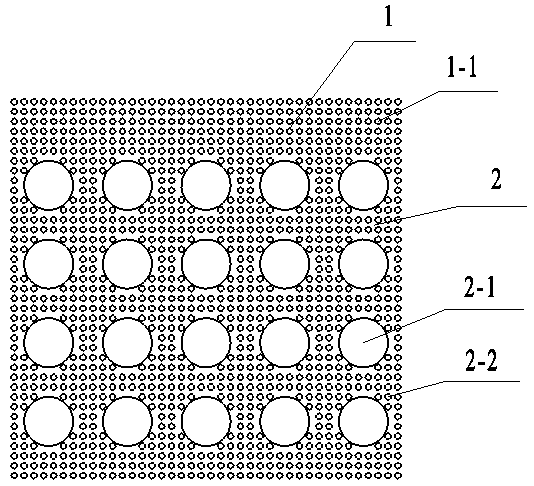

[0027] In this example, see figure 1 The gradient porous material in this embodiment is porous tantalum, which is divided into two gradient levels. The first gradient level porous material 1 is porous tantalum with a pore diameter of 1-9 μm, and the pores 1-1 are interconnected. The second gradient level porous material 2 It is a two-stage porous tantalum, the diameter of the large pores 2-1 is 1200-1500 μ...

Embodiment 2

[0035] A gradient porous material, wherein the gradient of the porous material is graded, and is graded according to the pore size of the pores in the gradient porous material body. The porous material formed by larger pores, the pores of the gradient porous materials that constitute the gradient porous material are interconnected, and in this example, the interface area of two adjacent gradient porous materials is larger than that of two adjacent gradient porous materials. For hierarchical porous materials, the plane is used as the area of the plane of the interface.

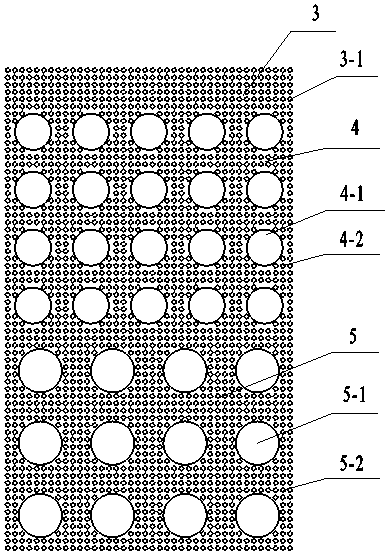

[0036] In this example, see the specific structure figure 2 , the gradient porous material in this example is Al 2 o 3 , divided into 3 gradient levels, the first gradient level porous material 3 (that is, the smallest gradient level porous material), is porous Al with a pore size of 20-40 μm 2 o 3 , the pores 3-1 are connected to each other, and the second gradient-level porous material 4 is two-level...

Embodiment 3

[0044] The gradient porous material of this embodiment is porous titanium, and its structure is similar to that of Example 1. The difference is that the first gradient-level porous titanium is porous titanium with a pore diameter of 700-900 nm, and the second gradient-level porous titanium is three-level porous titanium. The first-stage pore diameter is 400-600 μm, and its cavity wall is composed of the second-stage porous titanium with a pore diameter of 40-70 μm. The cavity wall of the second-stage porous titanium is composed of the third-stage porous titanium with a pore diameter of 700-900 nm. The graded porous titanium is the same material as the first gradient graded porous titanium.

[0045] The preparation method of this kind of porous titanium is as follows:

[0046] (1) Material preparation

[0047] Titanium powder with a particle size of 200-300nm is used as raw material, urea with a particle size of 800nm-1000nm is used as the smallest primary pore-forming agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com