Executing device, size degradation slurry all-in-one machine and kitchen garbage treating system

An execution device and a technology for kitchen waste, which are applied in grain processing, solid waste removal, etc., can solve the problems of high investment and operation costs, difficult separation of light and heavy impurities, complicated and cumbersome process technology, etc. The effect of rapid disintegration and pulping, convenient processing and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

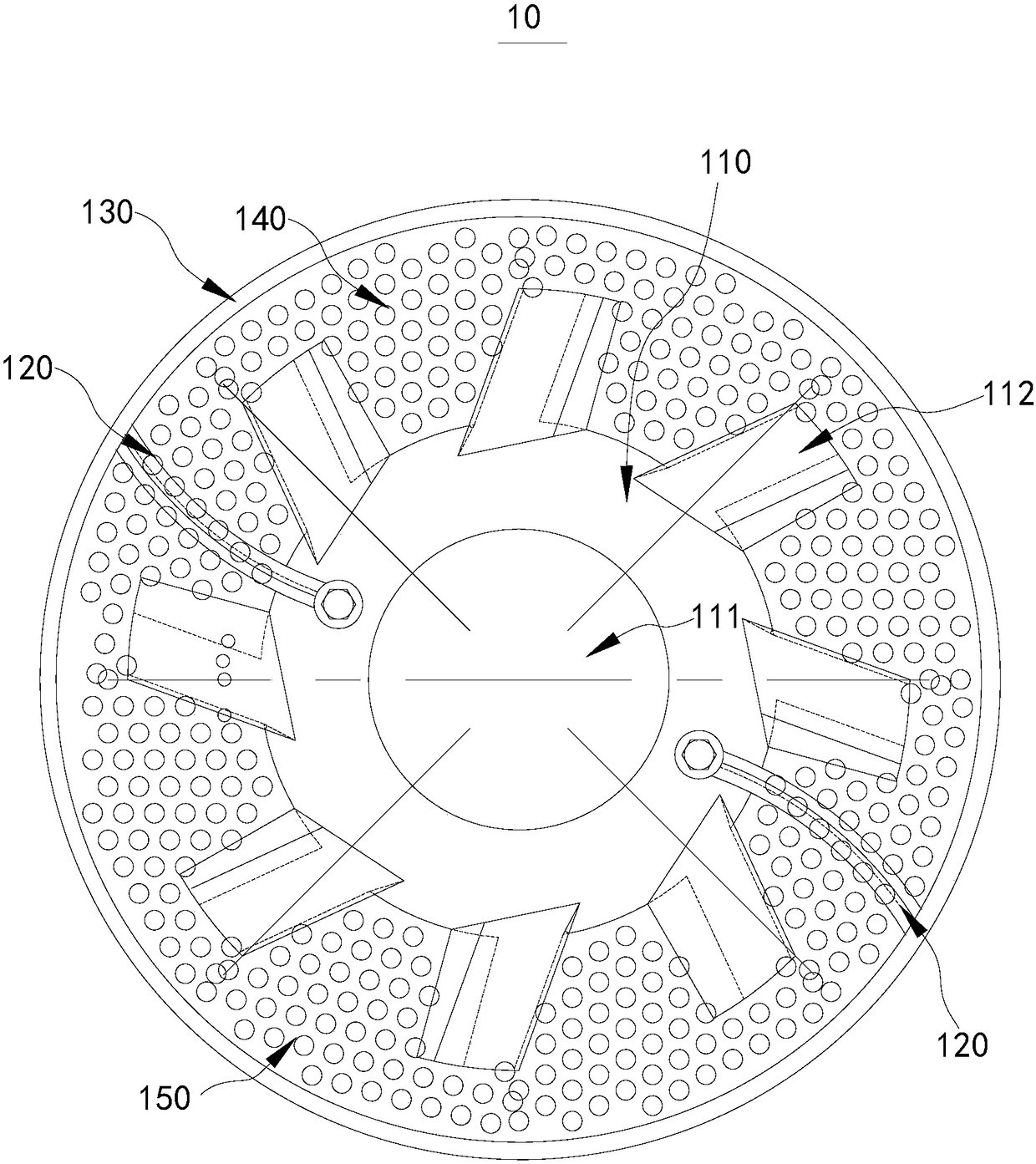

[0066] Please refer to figure 1 , figure 1 It is a schematic structural diagram of an execution device 10 provided by an embodiment of the present invention. From figure 1 It can be seen that an actuator 10 includes a cutterhead rotor 110 , a rotor swing arm 120 , a cutterhead stator 130 and a stator sieve disk 140 .

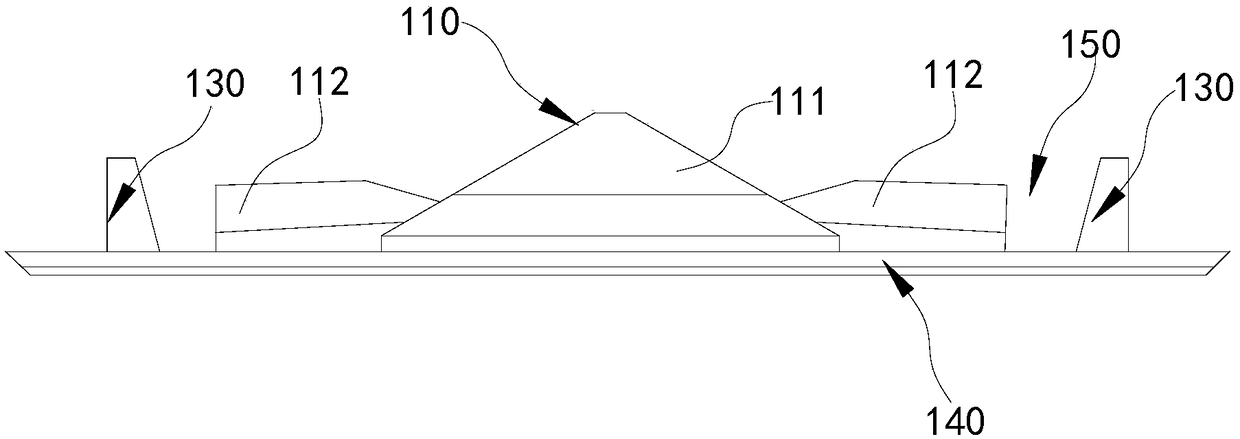

[0067] figure 2 for figure 1 Schematic diagram of the structure from another perspective. Please refer to figure 1 and figure 2 , it can be seen from the figure that the cutterhead stator 130 is an annular structure arranged on the periphery of the stator sieve disk 140;

[0068] The cutterhead stator 130 and the stator sieve tray 140 jointly form a housing space 150 for crushing and depulping kitchen waste; the cutterhead stator includes an annular bottom (not shown in the figure) and is circumferentially arranged on the bottom A plurality of toothed columns (not shown in the figure). The cutterhead rotor 110 is located in the accommodation space 150...

Embodiment 2

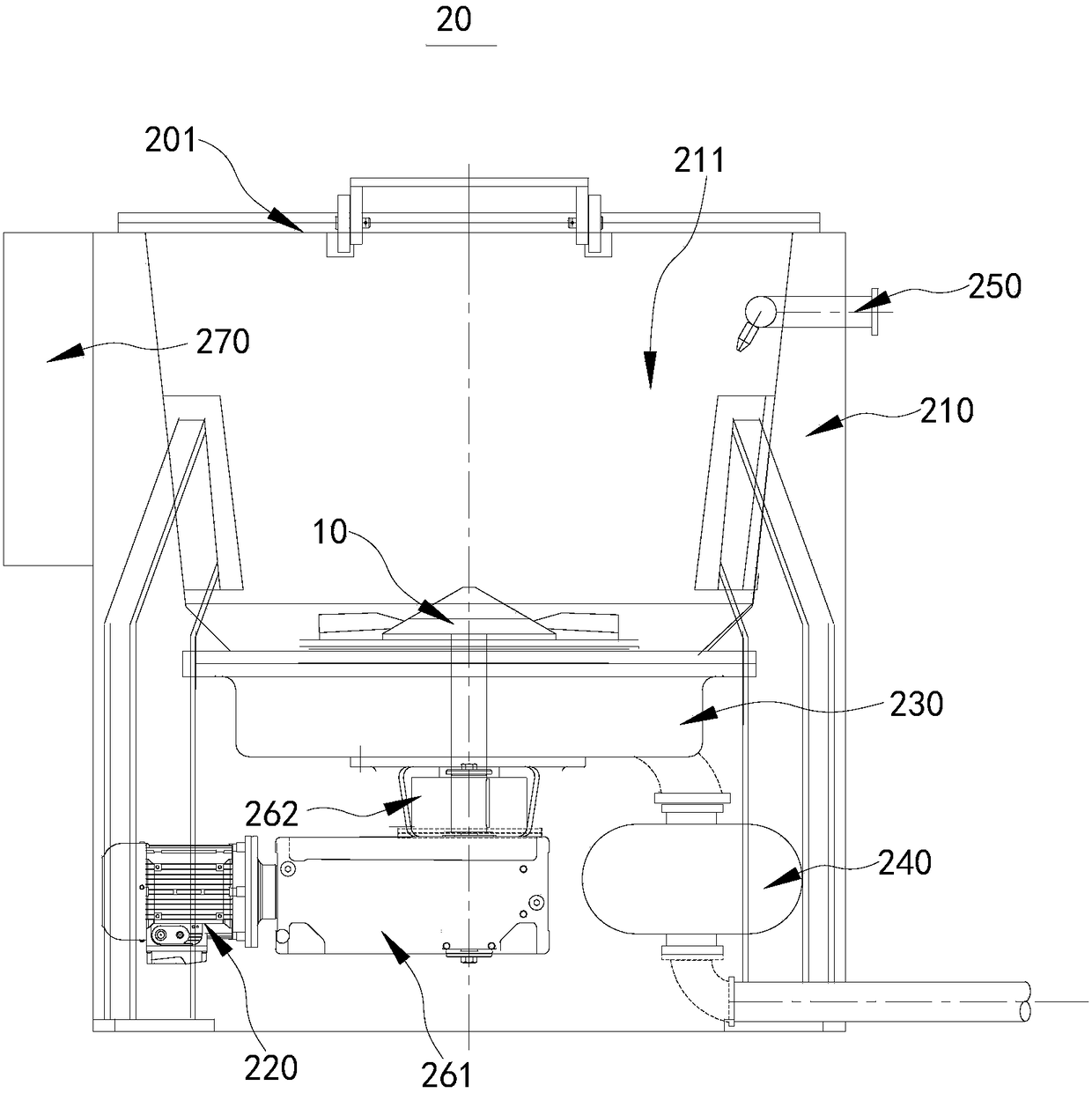

[0080] This embodiment provides an integrated crushing and pulping machine 20, which includes a main body 210, a power device 220, a good pulp buffer chamber 230, a conveying device 240, and the execution device 10 of the first embodiment.

[0081] The main body 210 has an accommodating cavity 211 for storing garbage, and the accommodating cavity has an opening for kitchen waste to enter; the knife plate stator 130 and the stator sieve plate 140 are arranged at the bottom of the accommodating cavity 211 of the main body 210; the power unit 220 It is arranged on the main body 210, and the power unit 220 is connected to the cutterhead rotor 110 in transmission; the good pulp buffer chamber 230 is arranged under the bottom of the main body 210, and the good pulp buffer chamber 230 communicates with the stator sieve plate 140; the inlet of the conveying device 240 is connected to the The good pulp buffer chamber 230 is connected.

[0082] The all-in-one machine 20 for crushing and...

Embodiment 3

[0095] This embodiment provides a kitchen waste treatment system 30 , which includes a storage tank 32 , a transport device 33 , a decomposition treatment facility 34 , and the integrated shredding and depulping machine 20 of the second embodiment.

[0096] The outlet of the conveying device 240 of the crushing and depulping integrated machine 20 is connected to the inlet of the storage tank 32 ; the outlet of the storage tank 32 is connected to the decomposition treatment facility 34 through the transportation device 33 .

[0097] The kitchen waste treatment system 30 includes the above-mentioned integrated crushing and depulping machine 20 , which has all the beneficial effects of the above-mentioned integrated crushing and depulping machine 20 . The all-in-one shredding and depulping machine 20 can separately collect kitchen waste on the spot, shred and reduce it, and pulp it for storage. The pulped kitchen waste can be uniformly transferred to the kitchen treatment plant f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com