Tinidazole tablet and preparation method thereof

A technology for tinidazole tablets and nidazole tablets, which is applied in the direction of pharmaceutical formulas, medical preparations containing no active ingredients, medical preparations containing active ingredients, etc., can solve the problem of poor tablet compression process of tinidazole tablets and poor raw material availability. Poor compressibility and fluidity, poor smoothness of the tableting process, etc., to achieve the effects of shortening the disintegration time limit, good compressibility, and improving the disintegration time limit and dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0045] Embodiments 1-6 were prepared using the following wet one-step granulation process:

[0046] 1) Weighing ingredients: Weighing each raw material and auxiliary material according to the mass ratio;

[0047] 2) Preparation of adhesive solution: take pregelatinized starch and evenly disperse it in purified water, place it in a steam interlayer heating pot, heat and stir continuously to make it gelatinize to 90-95°C, and then it is ready; unless otherwise specified, the example The binder solution is prepared by dispersing pregelatinized starch as binder in purified water.

[0048] 3) Premixing: mix tinidazole, diluent, and 30%-70% disintegrant (internal addition) in the formulation amount in a mixer;

[0049] 4) Granulation: Turn on the boiling drying granulator, spray the binder solution prepared in step 2) for granulation, control the inlet air temperature, fan frequency, binder injection speed, atomization pressure, material temperature, etc. parameters, complete gran...

Embodiment 1

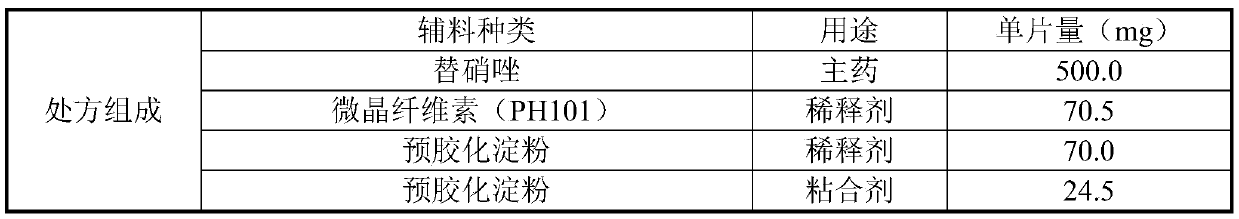

[0060] The formula is shown in Table 1.

[0061] Table 1

[0062]

[0063]

[0064] In the granulation process, step 2) prepares the binder solution: take the pregelatinized starch and disperse it evenly in purified water to make the concentration 6.5 (weight) %, place it in a steam interlayer heating pot, heat and continuously stir to make it paste Heat it up to 90-95°C to get it.

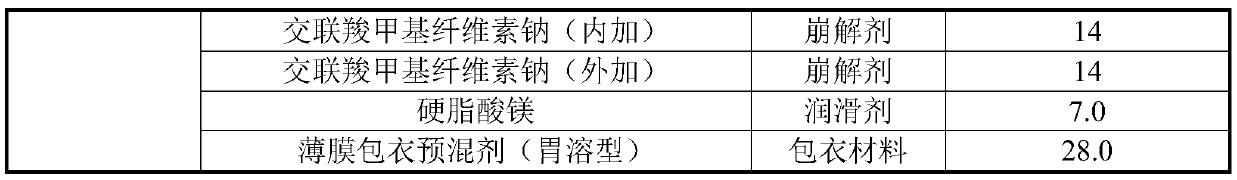

[0065] Prepare tinidazole tablets according to the aforementioned wet one-step granulation process, and detect the powder properties of the intermediate after step 5) granulation, and the disintegration time limit, hardness, friability and dissolution rate of the tablet, and detect The results are shown in Table 2.

[0066] Table 2

[0067]

Embodiment 2

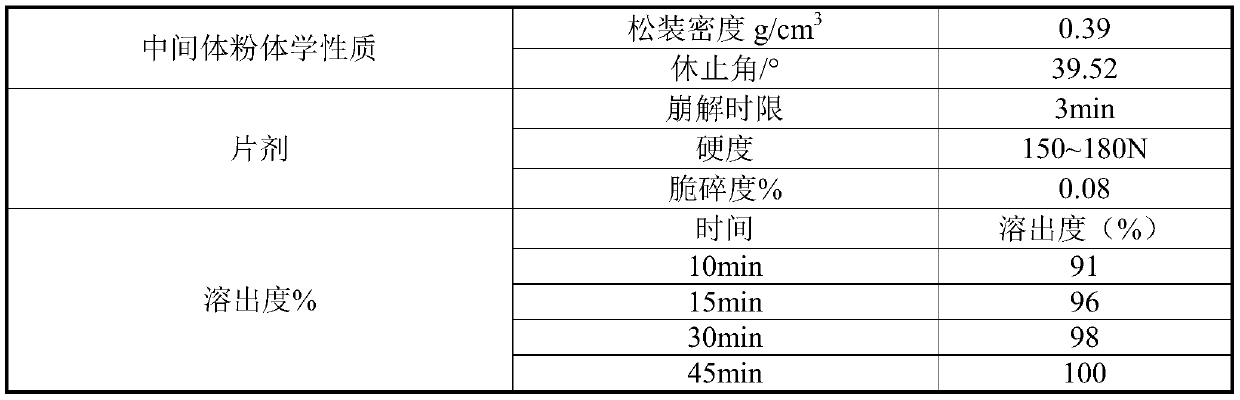

[0069] The recipe is shown in Table 3.

[0070] table 3

[0071]

[0072] In the granulation process, step 2) prepares the binder solution: take the pregelatinized starch and disperse it evenly in purified water to make the concentration 7.5% by weight, place it in a steam interlayer heating pot, heat and continuously stir to make it paste Heat it up to 90-95°C to get it.

[0073] Tinidazole tablets were prepared according to the aforementioned wet one-step granulation process, and the powder properties of the intermediate, the disintegration time limit, hardness, friability and dissolution rate of the tablet were tested. The test results are shown in Table 4.

[0074] Table 4

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com