The Method of Improving the Alloy Yield Rate in Strip Swing Process

A technology of alloy yield and alloy, which is applied in the field of improving alloy yield and improving alloy yield in stripping process, can solve the problems of reducing alloy yield, large volume of melting furnace, high cost, etc., and achieves improvement of alloy yield Yield, on-site operability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

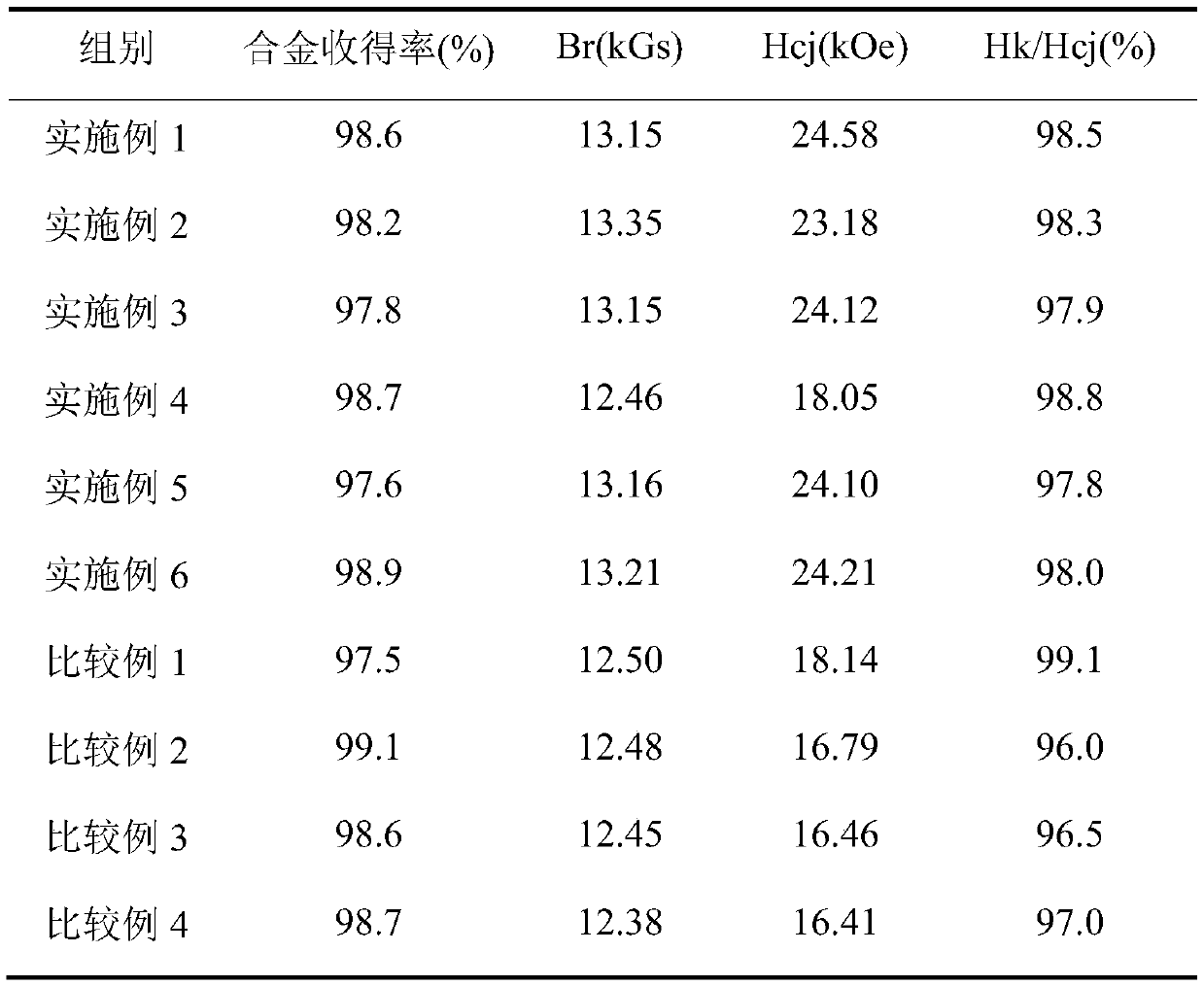

Embodiment 1

[0025] Add residual steel with the same formula as the alloy to the alloy. The amount of residual steel added is 1.5% of the weight of the alloy, and then heated and melted to obtain a liquid mixture. When the temperature of the liquid mixture is 1480°C, pour the liquid mixture , to get the strip strip, when the temperature of the strip strip drops to 80°C, remove it, and measure the alloy yield and magnetic properties (including remanence Br, intrinsic coercive force Hcj, squareness Hk / Hcj) of the strip strip ); the residual steel is the part where the liquid alloy splashes on the runner and adheres to the inner wall of the runner after solidification.

[0026] Among them, after the strip sheet was produced in the previous heat, the residual steel was collected, classified and pretreated according to the formula and grade of the alloy used in the previous heat; the above pretreatment process included: using steel with a diameter of 0.5mm The pellets are used to polish the res...

Embodiment 2

[0028] Add residual steel with the same formula as the alloy to the alloy. The amount of residual steel added is 1.0% of the weight of the alloy, and then heated and melted to obtain a liquid mixture. When the temperature of the liquid mixture is 1400 ° C, the liquid mixture is poured , to get the strip strip, when the temperature of the strip strip drops to 80°C, remove it, and measure the alloy yield and magnetic properties (including remanence Br, intrinsic coercive force Hcj, squareness Hk / Hcj) of the strip strip ); the residual steel is the part where the liquid alloy splashes on the runner and adheres to the inner wall of the runner after solidification.

[0029] Among them, after the strip sheet was produced in the previous heat, the residual steel was collected, classified and pretreated according to the formula and grade of the alloy used in the previous heat; the above pretreatment process included: using steel with a diameter of 1.0mm The pellets are used to polish ...

Embodiment 3

[0031] Add residual steel with the same grade as the alloy to the alloy. The amount of residual steel added is 0.5% of the weight of the alloy, and then heated and melted to obtain a liquid mixture. When the temperature of the liquid mixture is 1450 ° C, the liquid mixture is poured , to get the strip strip, when the temperature of the strip strip drops to 80°C, remove it, and measure the alloy yield and magnetic properties (including remanence Br, intrinsic coercive force Hcj, squareness Hk / Hcj) of the strip strip ); the residual steel is the part where the liquid alloy splashes on the runner and adheres to the inner wall of the runner after solidification.

[0032] Among them, after the strip sheet was made in the previous heat, the residual steel was collected, classified and pretreated according to the formula and grade of the alloy used in the previous heat; the above pretreatment process included: using steel with a diameter of 1.5mm The pellets are used to polish the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com