High-temperature steaming resistant and easy-uncovered composite film and manufacturing method thereof

A technology of high-temperature cooking and composite film, which is applied in the field of packaging, can solve the problems of unsuitable equipment application, narrow heat-sealing window of composite film, limited improvement of heat resistance, etc. The effect of stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

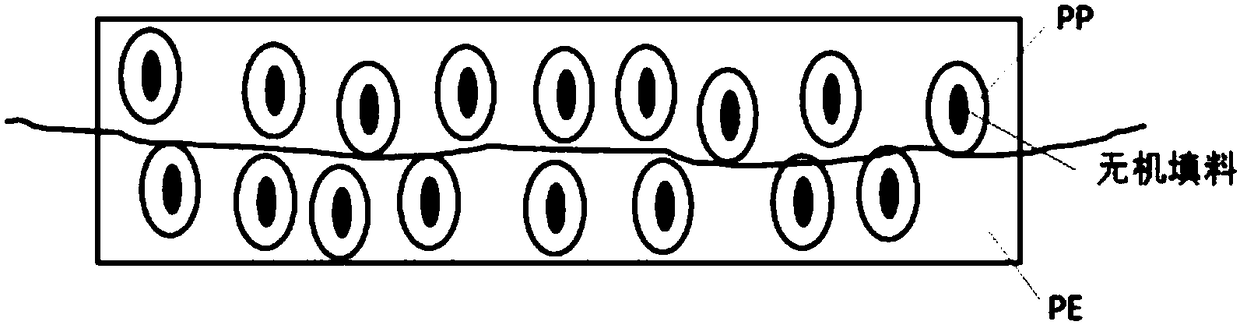

[0028] The invention is a kind of high-temperature cooking and easy-to-remove composite film, which includes a surface layer, a barrier layer and a heat-sealing layer arranged in sequence;

[0029] The surface layer is PET, biaxially oriented PET produced by Anhui Guofeng, the barrier layer is AL, and the alloy grade is 8011 from Zhongji Company. The proportion of the heat sealing layer is: 75% polyethylene particles, 15% polypropylene particles, and 10% talc. The talc is sieved through a 1000-mesh sieve. The talc is made of plastic-reinforced talc produced in Jiangxi Ao, and modified with KH550 silane coupling agent. (Stir in a high mixer for 20min) and dry after mixing. The composite glue adopts high temperature cooking glue. The polyethylene particles are low-density polyethylene, brand: Yanba 2426H, and the polypropylene particles are brand: Hyundai H1501. The melt flow index of polyethylene is 2-6g / 10min, the melting point is 90-100°C, and the density is 0.92g / cm3; the ...

Embodiment 2

[0034] The difference from Example 1 is that the barrier layer is aluminized PET, and the proportion of the heat-sealing layer is: 75% of polyethylene particles, 15% of polypropylene particles, and 10% of calcium carbonate. Calcium carbonate is sieved through a 1000-mesh sieve, and the superfine calcium carbonate adopts the superfine calcium carbonate produced in Jiangxi Ao Specialty. The amount of silane coupling agent added is 8% of the calcium carbonate mass, and repeated stirring (stirring in a high mixer for 15min) is mixed Then dry. High temperature cooking glue adopts Henkel UK3640.

Embodiment 3

[0036] The difference from Example 1 is that the proportion of the heat-sealing layer is: 75% of polyethylene particles, 15% of polypropylene particles, and 10% of calcium carbonate. Calcium carbonate is sieved through 1000 mesh sieves, adopts titanate coupling agent, and technique is that the concentration of titanate coupling agent is 5%, and the addition is 8% of calcium carbonate quality, repeats stirring (stirring in high mixer 30min) and dry after mixing. Bostik EPS6560 is used for high-temperature cooking glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com