Method for auxiliary growth of graphene by using composite metal on 6H/4H-SiC silicon surface

A composite metal and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of poor graphene uniformity, hinder the development of graphene, reduce the mobility of graphene, etc., and achieve the effect of good quality and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

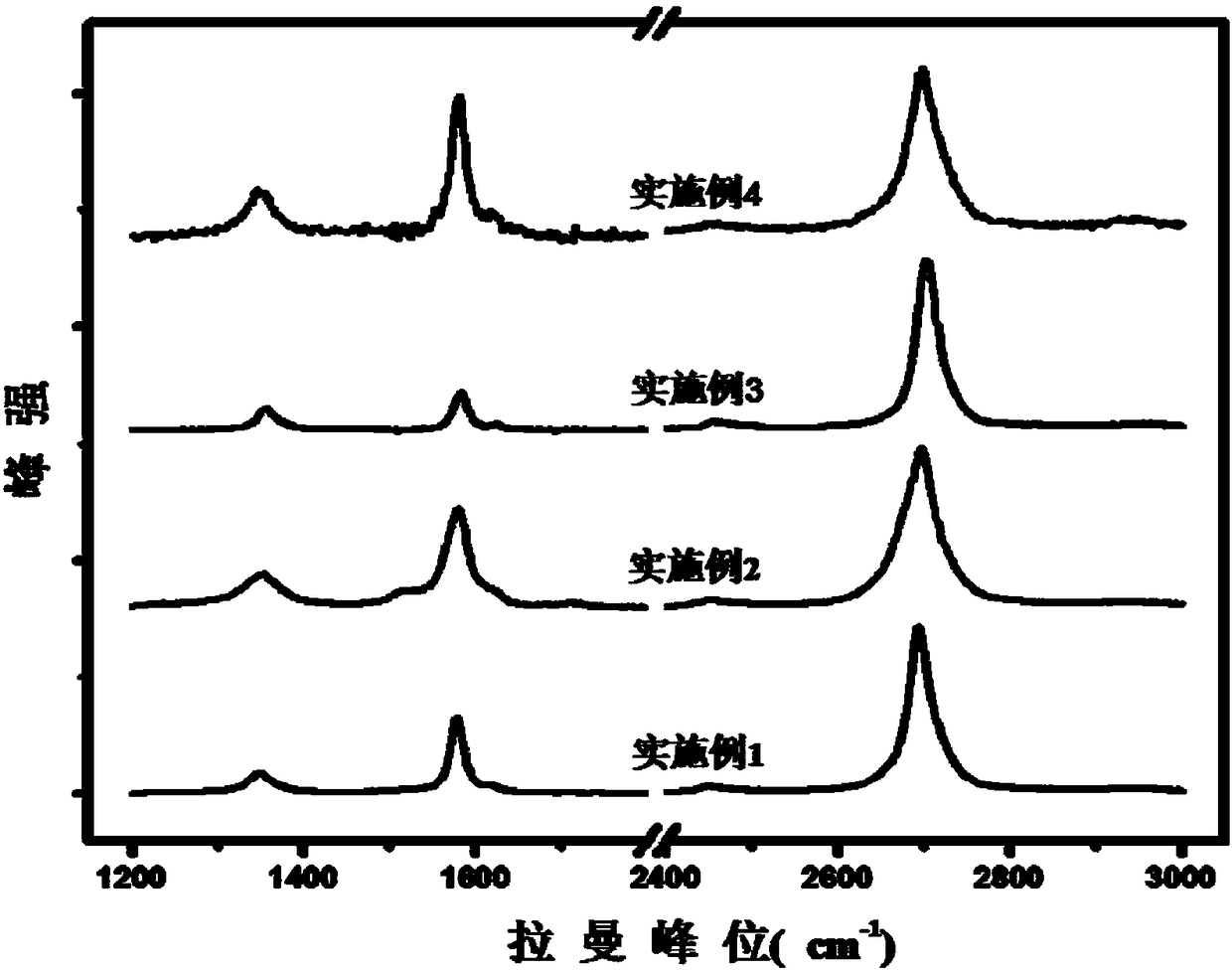

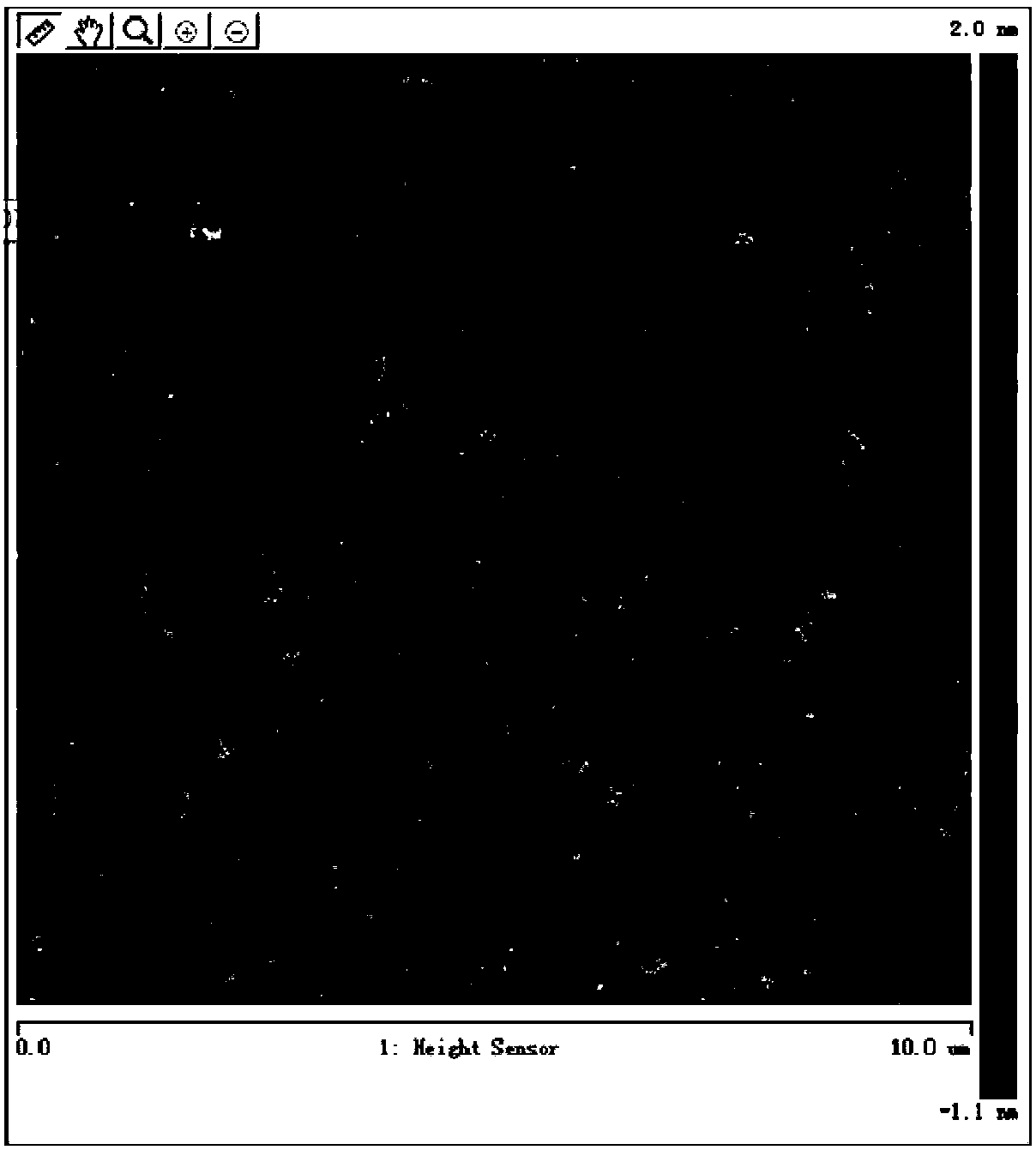

Examples

Embodiment Construction

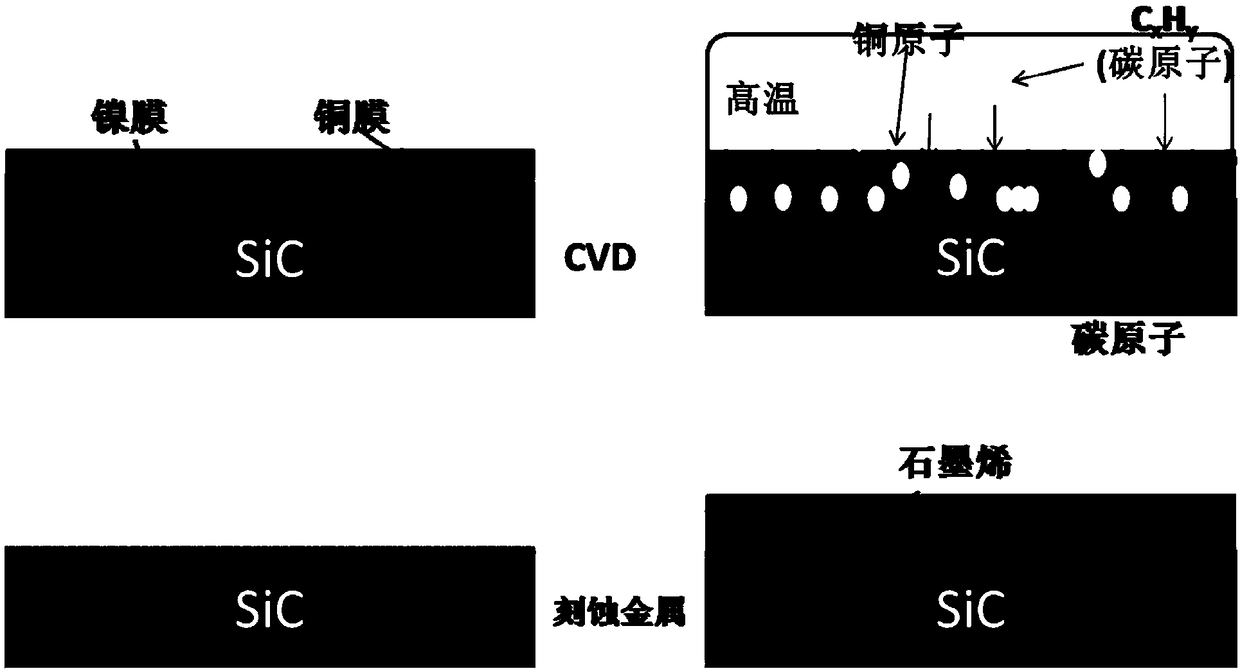

[0019] Technical scheme of the present invention is as follows:

[0020] A kind of method utilizing compound metal to assist the growth graphene on 6H / 4H-SiC silicon face, comprises the steps:

[0021] (1) Polishing, cutting, and cleaning the silicon surface of the 6H / 4H-SiC wafer to obtain a 6H / 4H-SiC wafer with a thickness of 300-400 μm;

[0022] (2) Place the 6H / 4H-SiC wafer processed in step (1) in the CVD furnace chamber with the silicon side facing up, vacuumize and rapidly raise the temperature to 1000-1100°C, and keep it warm for 5-20 minutes;

[0023] (3) Introduce high-purity argon and high-purity hydrogen into the reaction chamber, control the pressure at 300-800mbar, then raise the temperature to 1450-1600°C, and perform hydrogen etching on the SiC substrate of the 6H / 4H-SiC wafer for 10- 60min, cool down to room temperature, and obtain SiC substrate after hydrogen etching;

[0024] (4) Deposit a layer of carbon-dissolving and carbon-evolving metal with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com