A kind of anti-icing coating applied to transmission line and preparation method thereof

A transmission line and anti-icing technology, applied in coatings, circuits, electrical components, etc., can solve the problems of poor anti-icing ability of super-hydrophobic coatings, limited effect of anti-icing coatings, and increased cable line loss, etc. Inexpensive, good mechanical properties, enhanced thermal energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

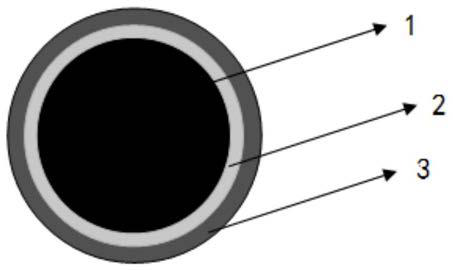

Image

Examples

Embodiment 1

[0043] A preparation method of anti-icing coating of the present invention:

[0044] (1) Weigh 1 kg of Fe 2 O 3 , 1 kg Co 2 O 3 , 1.5 kg MnO, 1 kg Al 2 O 3 , 1.5kg NiO, 0.5kg CuO, 0.1kg La 2 O 3 , 0.1 kg Y 2 O 3 Mixing with a mixer, and then evenly grinding to a particle size of less than 1 micron by sand milling after mixing, to obtain mixed powder, calcined at 1000 ° C for 8 hours, after natural cooling, and then uniformly ground to particle size by sand milling method The diameter is less than 500 nanometers, and the light-converging energy-absorbing material is obtained;

[0045] (2) 3 kg of light-gathering absorbing material, 1 kg of magneto-heating material (Fe 3 O 4 ) and 1.5 kilograms of film-forming base materials (0.5 kilograms of potassium silicate and 1.0 kilograms of epoxy resins) by mechanical mixing, high-speed dispersion for 3 hours at a rotating speed of 1500r / min, to obtain the composition A for preparing the energy-gathering layer;

[0046] (3) 4 k...

Embodiment 2

[0050] A preparation method of anti-icing coating of the present invention:

[0051] (1) Weigh 1 kg of Fe 2 O 3 , 1 kg Co 2 O 3 , 1.5 kg MnO, 1 kg Al 2 O 3 , 1.5kg NiO, 0.5kg CuO, 0.1kg La 2 O 3 , 0.1 kg Y 2 O 3 Mixing with a mixer, and then evenly grinding to a particle size of less than 1 micron by sand milling after mixing, to obtain mixed powder, calcined at 1000 ° C for 8 hours, after natural cooling, and then uniformly ground to particle size by sand milling method The diameter is less than 500 nanometers, and the light-converging energy-absorbing material is obtained;

[0052] (2) 3 kg of light-gathering absorbing material, 3 kg of magneto-heating material (Fe 3 O 4 ) and 1.5 kilograms of film-forming base materials (0.5 kilograms of potassium silicate and 1.0 kilograms of epoxy resins) by mechanical mixing, high-speed dispersion for 3 hours at a rotating speed of 1500r / min, to obtain the composition A for preparing the energy-gathering layer;

[0053] (3) 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com