Anti-icing material and preparation method and application thereof

An anti-icing and ground wire technology, applied in the direction of climate change adaptation, radiation-absorbing coatings, coatings, etc., can solve the problems of insulator operation safety hazards, transmission power loss, etc., and achieve high anti-icing efficiency, high production efficiency, insulation good sex effect

Active Publication Date: 2018-09-28

STATE GRID HUNAN ELECTRIC POWER +2

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, Chinese patent application CN105283931A introduces an anti-icing method for coating piezoelectric materials on transmission lines, which uses piezoelectric coatings to cause resistance heating on the outer surface of cables for deicing, but this method is only applied to The anti-icing of transmission lines is not suitable for insulators, iron towers and ground wires that do not pass current under normal operation; Chinese patent application CN1995251A introduces an anti-icing material that coats insulators with electrification and heat generation properties and its preparation method , this method melts ice through Joule heat and field effect heat generated by leakage current, but this method brings safety hazards to the operation of insulators, and will cause loss of transmission power due to continuous current flow

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0028] 2Kg Co-Al-O metal composite oxide, 1.5Kg Cu-Mn-O metal composite oxide, 1.0Kg calcium silicate, 0.5Kg calcium aluminate, 1.5Kg methyl tributyl ketoximosilane, 1Kg tridecano Fluoroctyltriethoxysilane, 4Kg nano-silica alumina gel, and 0.2Kg MgO are mechanically mixed and dispersed at a high speed of 1000-2000r / min for 2-3 hours to obtain the uniformly dispersed anti-icing material of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

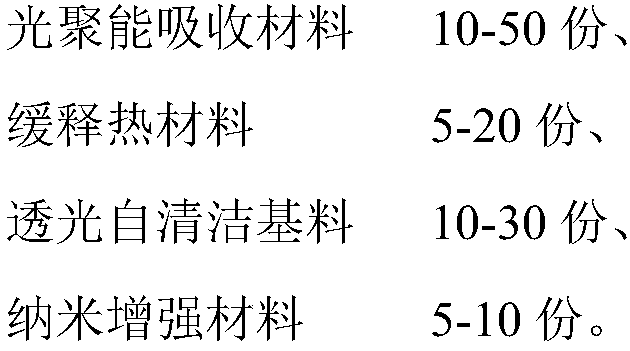

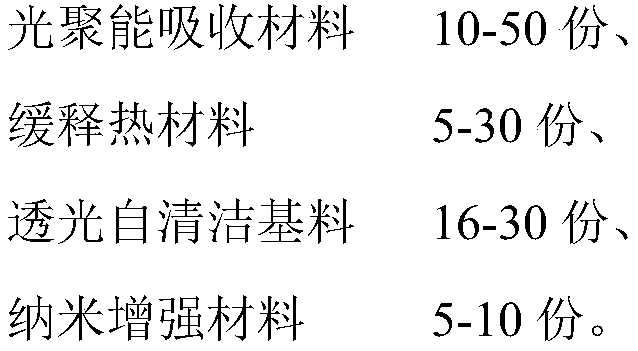

The invention provides an anti-icing material and also correspondingly provides a preparation method and application of the anti-icing material. The anti-icing material comprises the following ingredients (by weight): 10-50 parts of a light energy absorbing material, 5-30 parts of a slow-release hot material, 16-30 parts of a light-transmission self-cleaning base-material, and 5-10 parts of a nanometer reinforcing material. The anti-icing material of the invention is suitable for anti-icing of insulators, iron towers and ground wires, and has advantages of high anti-icing efficiency, good insulativity, long period of validity, good economy and the like. The preparation method of the anti-icing material has advantages of simple operation and high production efficiency. The application of the anti-icing material has advantages of simple technological process and simple operation.

Description

technical field [0001] The invention belongs to the field of functional materials, in particular to an anti-icing material and its preparation method and application. Background technique [0002] As we all know, icing disasters seriously threaten the safe and stable operation of power grids. Due to the large number and wide distribution of power grid lines, most of them are located in the harsh micro-terrain and micro-climate alpine mountainous areas, which are extremely vulnerable to the impact of rain, snow and freezing, and the icing situation is very serious. Once an icing accident occurs, it will seriously affect people's health. Normal production and domestic electricity consumption. [0003] Nowadays, there are few related researches on anti-icing coatings and all of them have their limitations. For example, Chinese patent application CN105283931A introduces an anti-icing method for coating piezoelectric materials on transmission lines, which uses piezoelectric coa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D183/08C09D5/32C09D5/25H01B7/28H01B17/50

CPCC08K3/24C08K3/34C08K3/36C08K2003/222C08K2003/2227C08K2003/2248C08K2003/2262C08K2003/2289C08K2201/011C09D5/32C09D183/08H01B3/308H01B7/28H01B17/50Y02A30/14

Inventor 陆佳政陈宝辉方针金灵华潘碧宸梁平李波

Owner STATE GRID HUNAN ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com