Controlled degradation magnesium-based functional gradient material and preparation method thereof

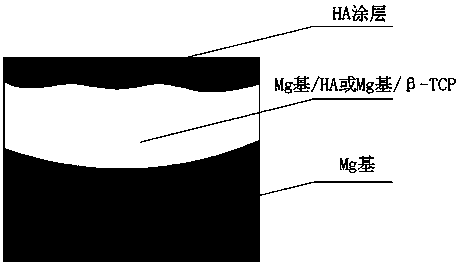

A technology of functionally graded materials and base materials, applied in electrolytic coatings, metal material coating processes, coatings, etc., can solve problems such as poor corrosion resistance, poor controllability of degradation, inability to be absorbed and degraded, and achieve high bonding strength. , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

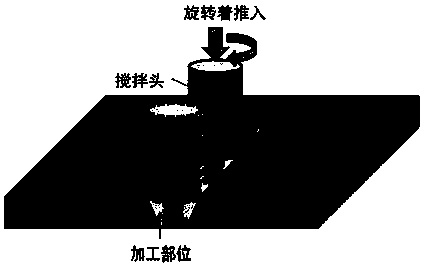

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a controllable degradation magnesium-based functionally graded material, comprising the following steps:

[0039] 1) The size of the as-cast Mg-Zn-Y-Nd plate is 200mm×50mm×8mm, and it is subjected to homogenization annealing treatment, the annealing temperature is 500°C, and the holding time is 120 hours, and the annealed magnesium alloy plate is taken out of the heat treatment furnace , naturally cooled at room temperature;

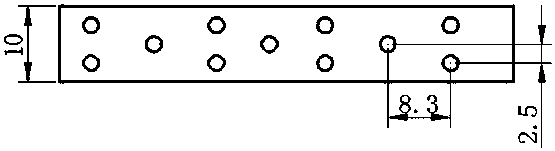

[0040] 2) Polish the surface until it is bright, and drill holes with a drill bit with a diameter of 4mm. The hole distribution is designed to be 3 rows, and the distance between the rows is 2.5mm. The distance between the holes in the same row is 16.6mm, and the hole diameter is 4mm. The hole depth is 4mm, and the distribution and quantity of the holes are referred to the stirring needle (see image 3 ), loading of hydroxyapatite (HA) after drilling;

[0041] 3) Fix the magnesium alloy plate loaded with HA on the friction...

Embodiment 2

[0052] A method for preparing a controllable degradation magnesium-based functionally graded material, comprising the following steps:

[0053] 1) The size of the as-cast Mg-Zn-Y-Nd plate is 200mm×50mm×8mm, and it is subjected to homogenization annealing treatment at an annealing temperature of 450°C and kept for 80 hours, and the annealed magnesium alloy plate is taken out of the heat treatment furnace , naturally cooled at room temperature;

[0054] 2) Polish the surface until it is bright, and drill holes with a drill bit with a diameter of 2mm. The hole distribution is designed to be 4 rows, and the distance between the rows is 1mm. The distance between the holes in the same row is 3mm, and the hole diameter is 2mm. The depth is 2mm, and the loading of hydroxyapatite (HA) is carried out after the drilling is completed;

[0055] 3) Fix the magnesium alloy plate loaded with HA on the friction stir processing workbench for friction stir processing. The amount is 1.5mm, and ...

Embodiment 3

[0060] A method for preparing a controllable degradation magnesium-based functionally graded material, comprising the following steps:

[0061] 1) The size of the as-cast Mg-Zn-Y-Nd plate is 200mm×50mm×8mm, and it is subjected to homogenization annealing treatment, the annealing temperature is 200°C, and the holding time is 12 hours. The annealed magnesium alloy plate is taken out from the heat treatment furnace, and cooled naturally at room temperature;

[0062] 2) Polish the surface until it is bright, and drill holes with a drill bit with a diameter of 0.5mm. The hole distribution is designed to be 6 rows, the distance between rows is 3mm, the distance between holes in the same row is 1mm, and the hole diameter is 0.5mm , the hole depth is 1mm. Hydroxyapatite (HA) loading after drilling;

[0063] 3) Fix the magnesium alloy plate loaded with HA on the friction stir processing workbench for friction stir processing. The amount is 0.5mm, and the Mg base / HA layer with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com