Adjustable-crack type temporary plugging acid fracturing steering performance testing device and evaluation method

A technology of steering performance and testing equipment, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems that the limitation of fracture size cannot evaluate the position of bridging formed by temporary plugging agent, so as to improve accuracy, The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

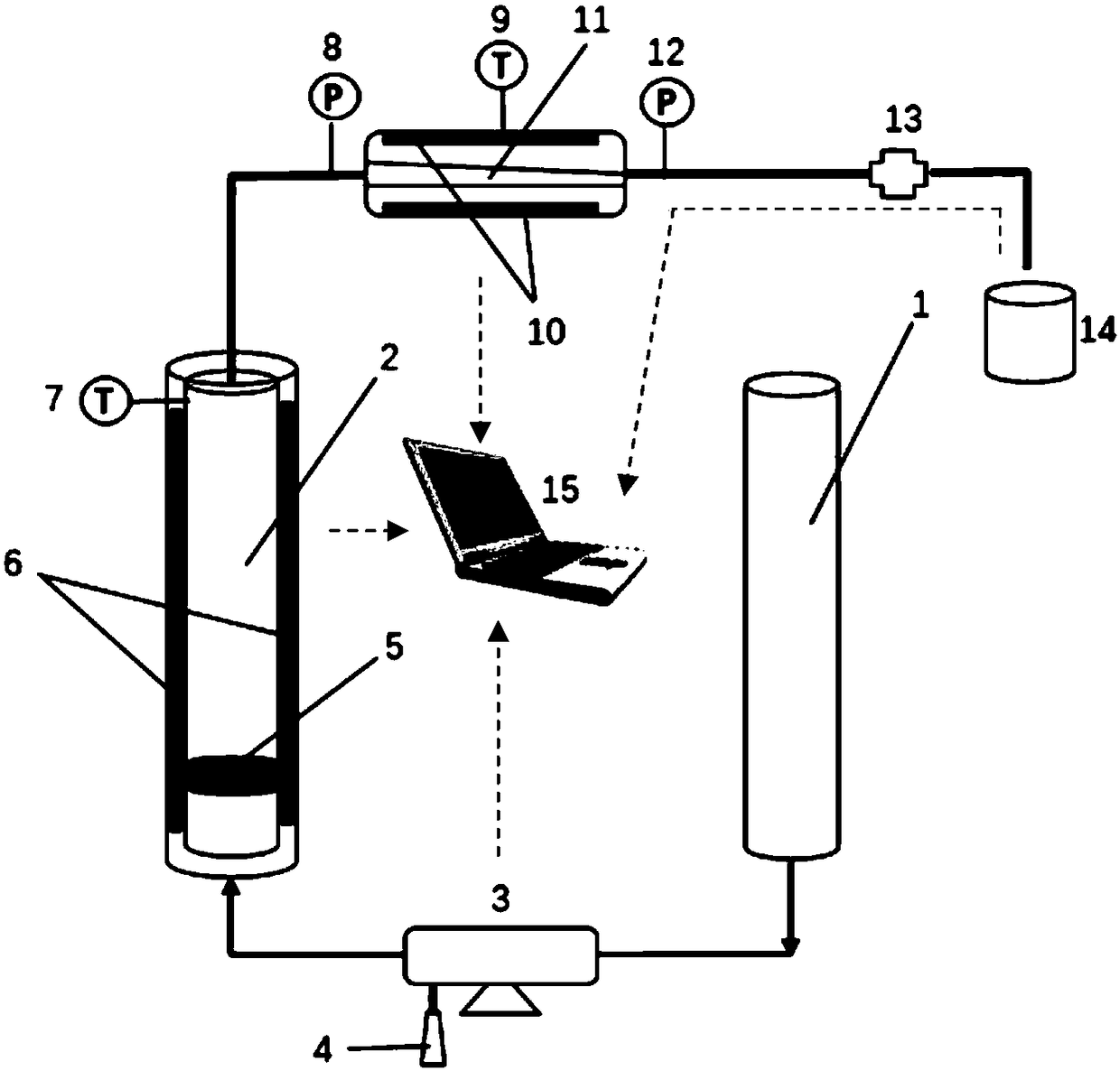

Method used

Image

Examples

Embodiment 1

[0036] The simulated crack in this embodiment is a wedge-shaped crack, the size of the exit is 3 mm, the size of the crack at the entrance is 5.1 mm, the lower wall of the crack is parallel to the horizontal plane, the angle between the upper wall and the horizontal plane is 0.5 degrees, and the crack shape is a wedge-shaped crack;

[0037] Preparation of thickened acid solution: 0.6% polymer thickener + 15% HCl + 1% corrosion inhibitor, tested by HAAKE rheometer at 140°C, 170S -1 Its apparent viscosity is stable at 50mPa.s;

[0038] The temporary plugging agent is made of polyester fibers with a fiber length of 6 mm and an addition ratio of 1.5 wt%, which is dispersed in the thickened acid solution by high-speed stirring;

[0039] Set the temperature of the acid tank and the simulated crack temperature to 140°C, and the displacement of the plunger pump 3 to 220ml / min;

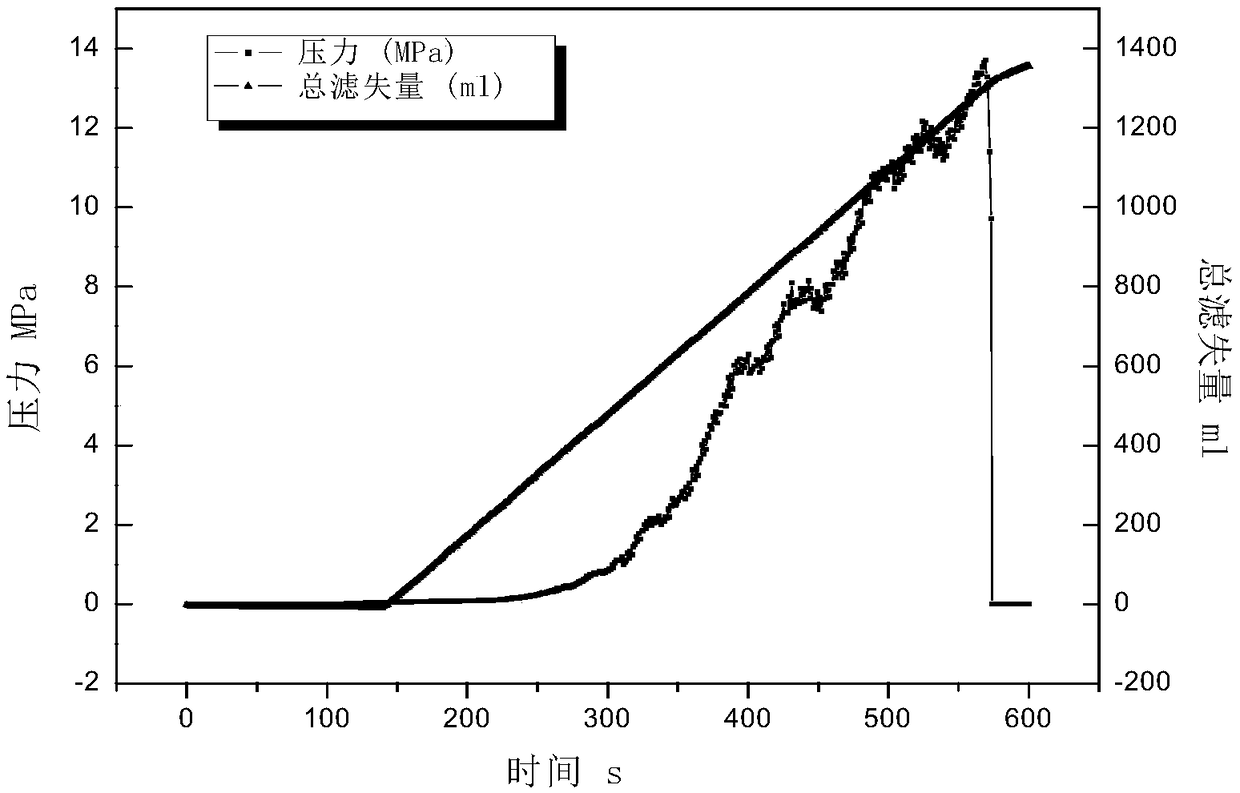

[0040] After starting the pump for a period of time, the pressure starts, and then the pressure rises to a c...

Embodiment 2

[0043] The experimental conditions of this example are basically the same as those of Example 1, except that the temporary plugging agent is: 1.5wt% polyester fibers + 0.5wt% polyester temporary plugging particles (average diameter: 2mm).

[0044] For wider fractures, the temporary plugging strength of pure fiber plugging agent is not enough, consider compounding rigid temporary plugging particles to increase the temporary plugging strength. Figure 4 It shows that 1.5wt% polyester fibers + 0.5wt% polyester temporary plugging particles (average diameter is 2mm) plug the wedge-shaped cracks in Example 1. After the plugging pressure reaches 22MPa, the safety valve automatically opens the pressure relief protection system . The experimental results show that the combination of rigid particles can significantly enhance the plugging strength.

Embodiment 3

[0046] The setting of the size and shape of the simulated crack in this embodiment: its shape is wedge-shaped, and three types of cracks of 8 sizes are set in the following table 1. For the convenience of marking, the cracks of each size take the size of the outlet end as the recording standard, i.e. 0.5, 1 , Eight sizes of 2, 3, 4, 6, 7, 8mm.

[0047] Table 1

[0048]

[0049] Thickened acid preparation: 0.6% polymer thickener + 15% HCl + 1% corrosion inhibitor, tested by HAAKE rheometer at 140°C, 170S-1, its apparent viscosity is stable at 50mPa.s;

[0050] The temporary plugging agent is made of polyester fibers with a fiber length of 6 mm and an addition ratio of 1.5 wt%, which is dispersed in the thickened acid solution by high-speed stirring;

[0051] Set the acid tank temperature and simulated crack temperature to 140°C;

[0052] Displacement settings are 50, 100, 150, 200, 250, 300, 350, 400, 500, 600, 700ml / min, a total of 11 displacements;

[0053] A total of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com