Directional purging system and method

A technology of reversing valve and purging gas, applied in combustion methods, gas fuel burners, indirect carbon dioxide emission reduction, etc., can solve problems such as energy waste, waste, etc., and achieve simple pipeline layout, high pressure, and fire breakout time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

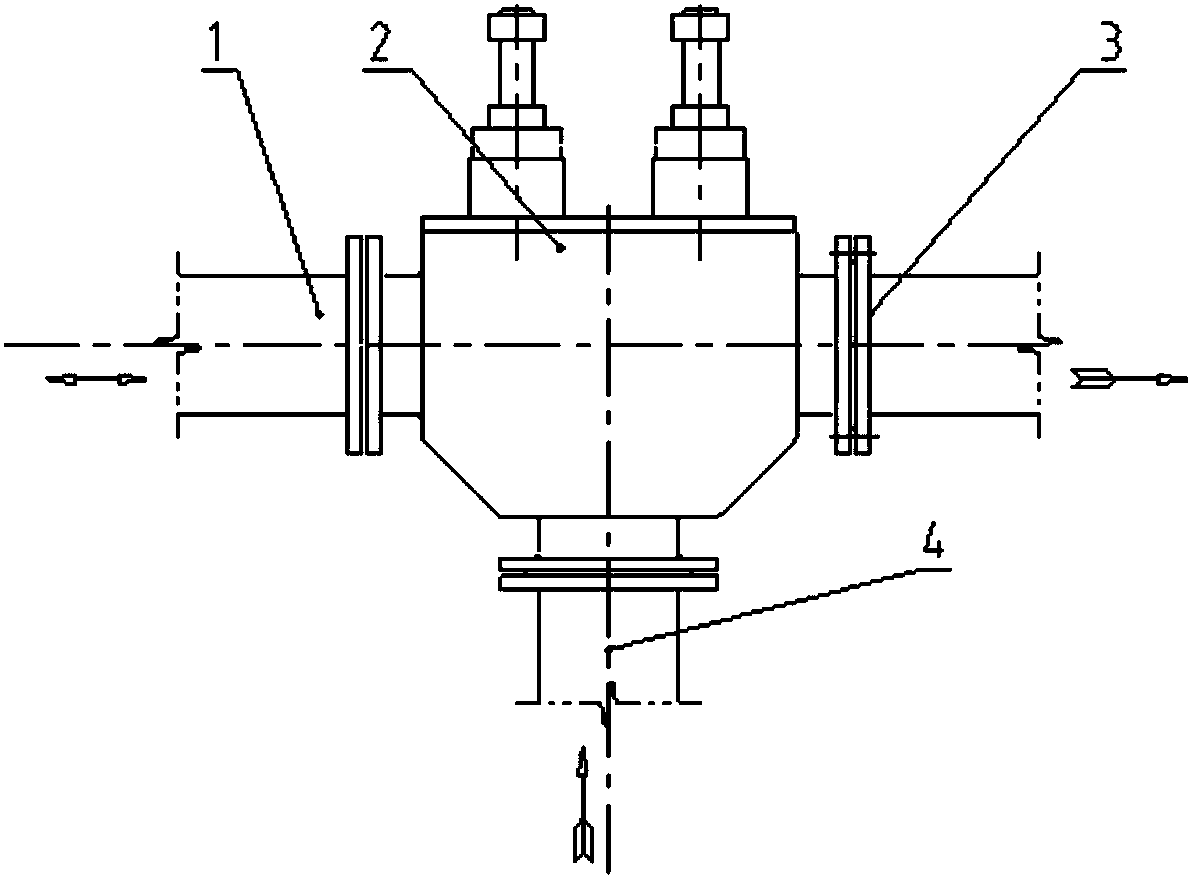

[0028] The inventive idea of the present invention is to install a reversing purge device on the reversing valve, and before each reversing valve action, the purge gas is introduced to blow the remaining gas in the pipeline into the furnace to make it participate in combustion.

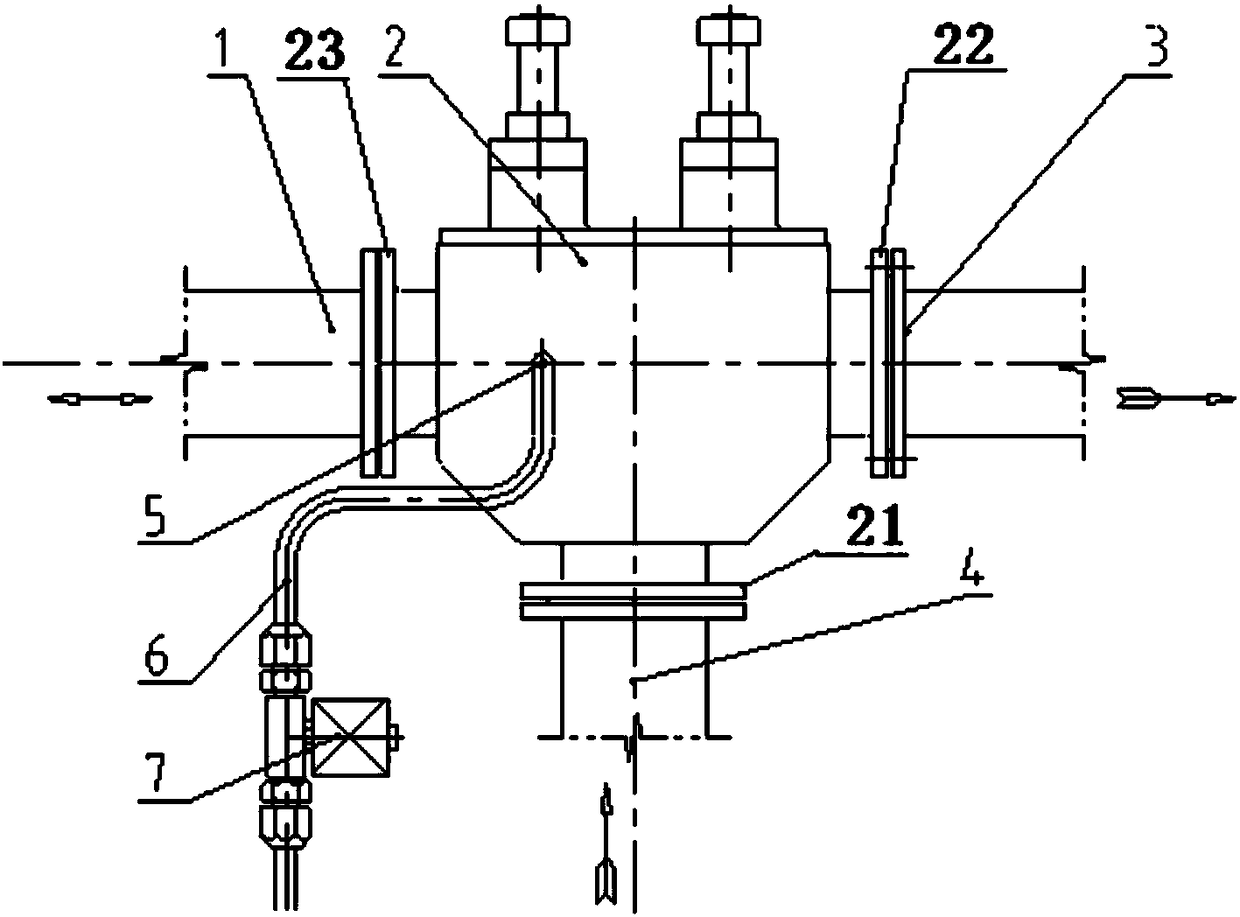

[0029] Such as figure 2 As shown, the reversing purge system provided by the present invention includes a reversing valve 2 and a purge device, wherein the reversing valve 2 includes a gas connection port 21, a flue gas connection port 22, The pipeline interface 23 before the burner; the purging d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com