Plane grating interferometer displacement measuring system

A flat grating, displacement measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of easy interference of measurement signals, complex optical structure, difficult to guarantee accuracy, etc. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure, principle and specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

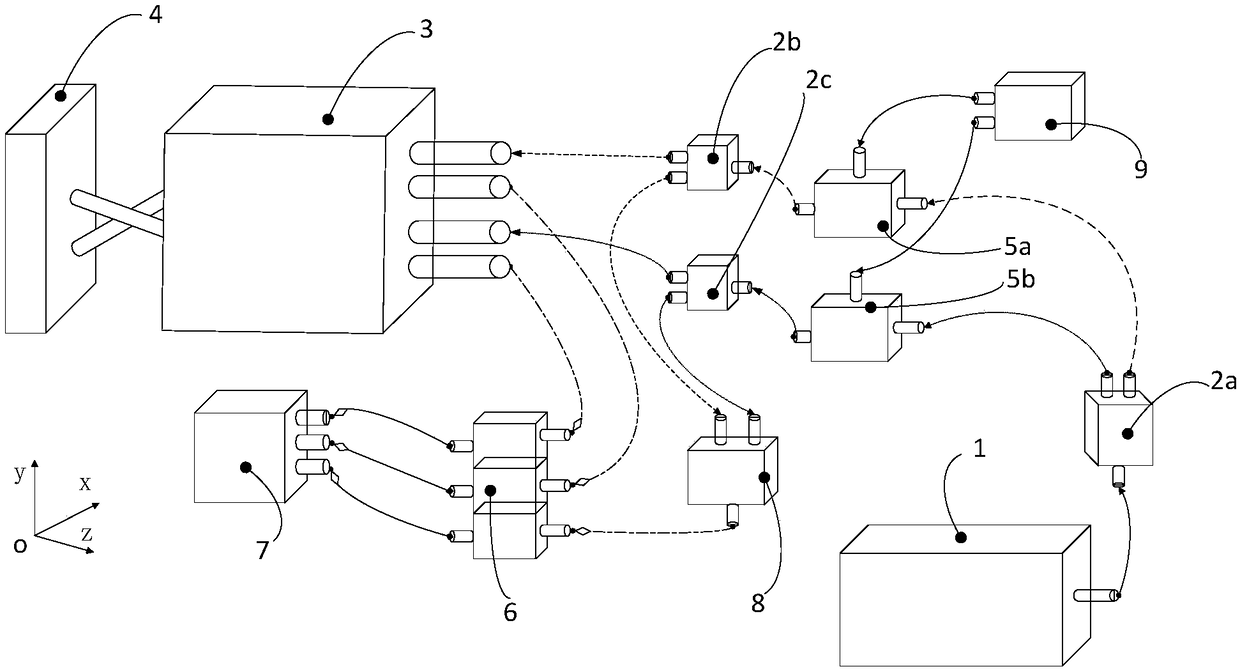

[0026] Please refer to figure 1 , the planar grating interferometer displacement measurement system includes a single-frequency laser 1, a beam splitter, a grating interferometer 3, a planar grating 4, an acousto-optic modulator, a receiver 6 and an electronic signal processing component 7, and the planar grating 4 is a two-dimensional reflection type grating.

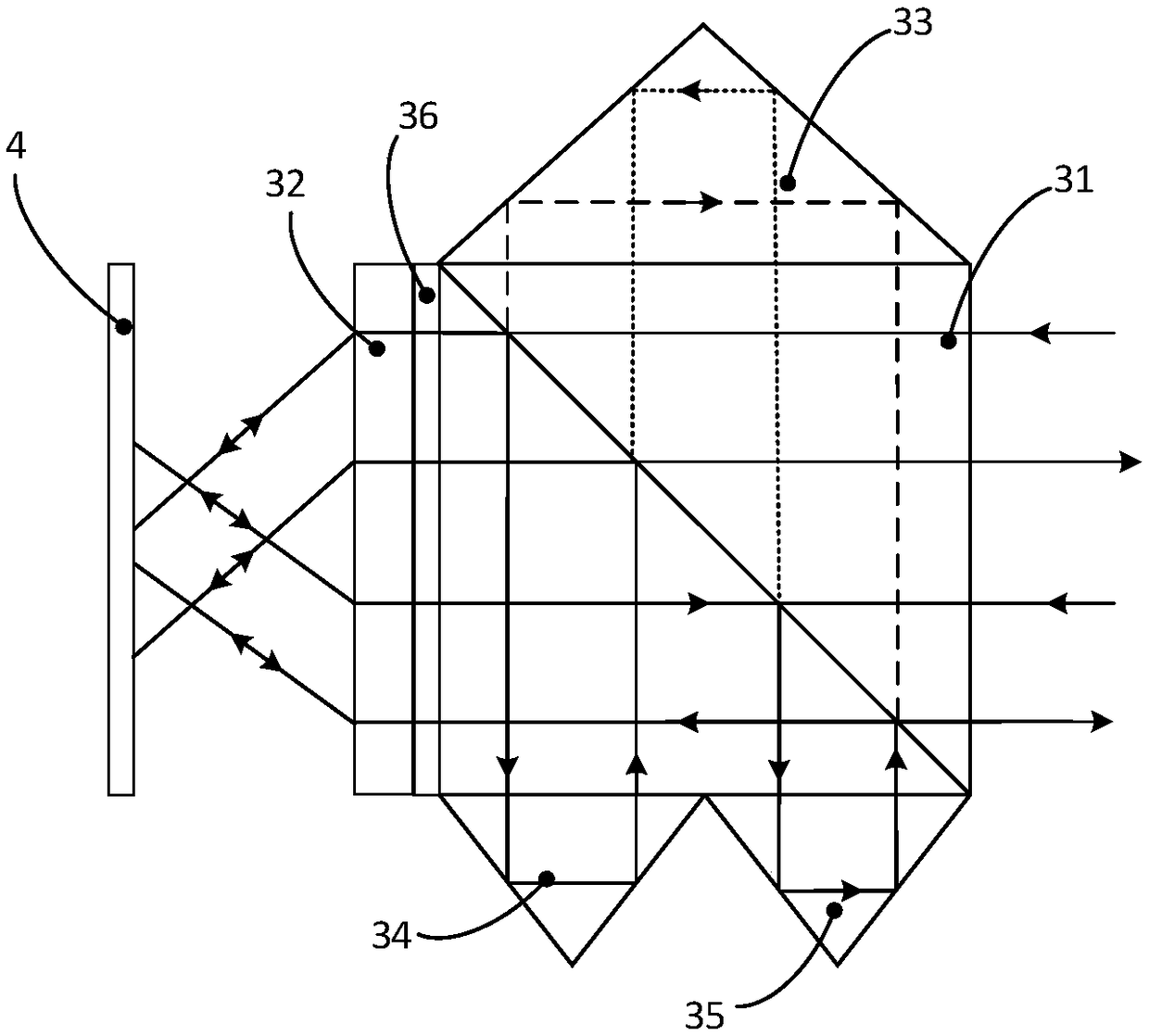

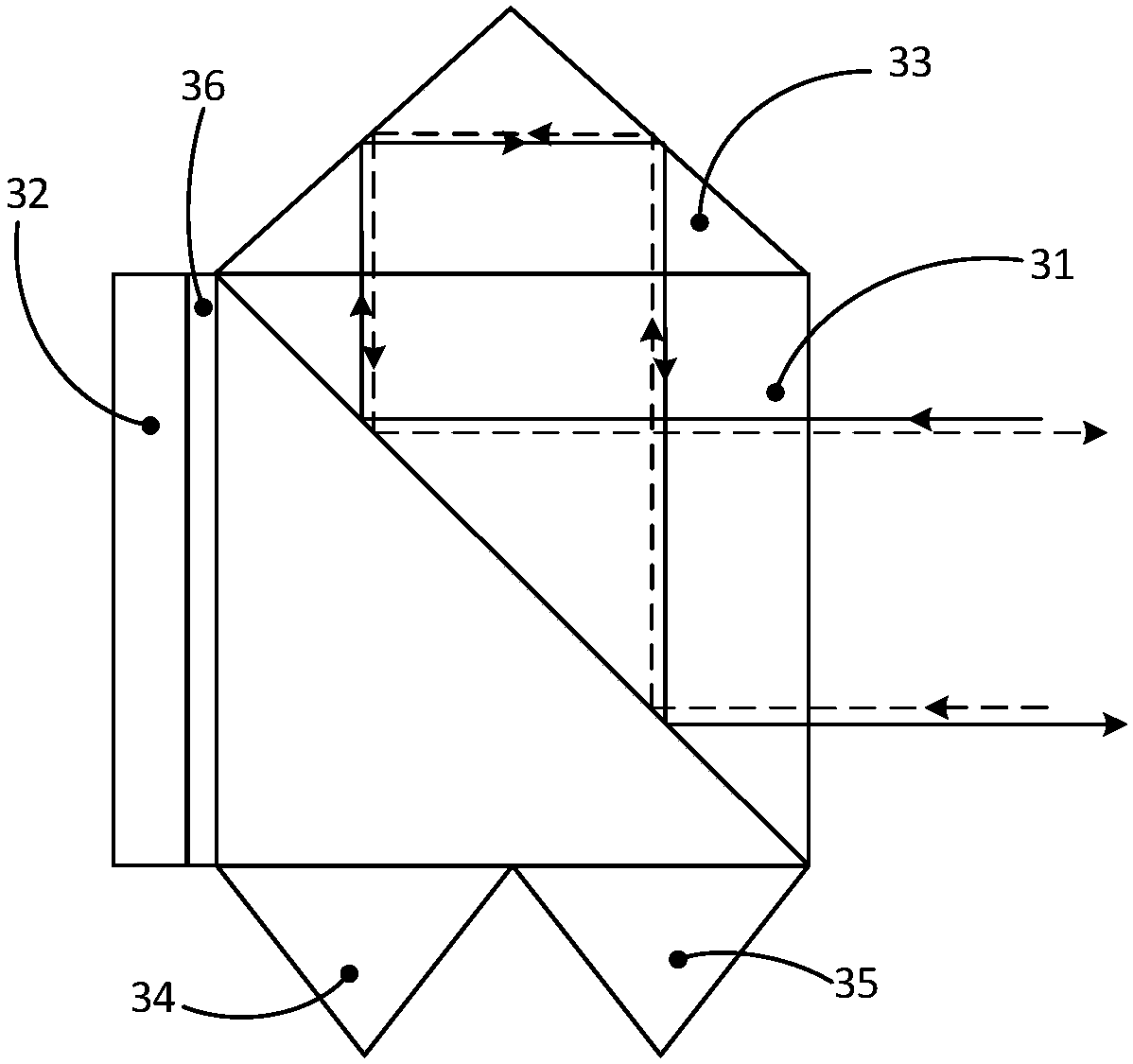

[0027] Please refer to figure 2 , the grating interferometer 3 includes a polarization beam splitter 31, a refractive element 32, a first right-angle prism 33, a second right-angle prism 34 and a third right-angle prism 35, a quarter wave plate 36, and a refractive element 32, wherein the first The right-angle prism 33 is located at the top of the polarization beam splitter, and the second right-angle prism 34 and the third right-angle prism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com