Zeolitic imidazolate frameworks with immobilized ionic liquid in cages and application of zeolitic imidazolate frameworks

A zeolite imidazolate, ionic liquid technology, applied in separation methods, other chemical processes, dispersed particle separation and other directions, can solve the problems of unattainable selectivity and poor selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a specific embodiment, the above-mentioned preparation method comprises the following steps:

[0035] (1) prepare ZIFs material and clean;

[0036] (2) Immerse the ZIFs material in the impregnating solution at 50°C-180°C for 1-96 hours, then wash and dry;

[0037] Wherein said impregnating solution is ionic liquid or by C 1-4 A mixed solution composed of low-carbon alcohol and ionic liquid in any proportion; preferably using C 1-4 A mixed solution with a low-carbon alcohol percentage not exceeding 95%;

[0038] (3) The product obtained in step (2) is cleaned and dried.

[0039] The lower carbon alcohol used in the dipping solution in the preferred step (2) is cleaned. After 3-5 times of washing, the product is dried at 30-100° C. for 12-48 hours to obtain the zeolite imidazolate framework material with ionic liquid immobilized in the cage of the present invention.

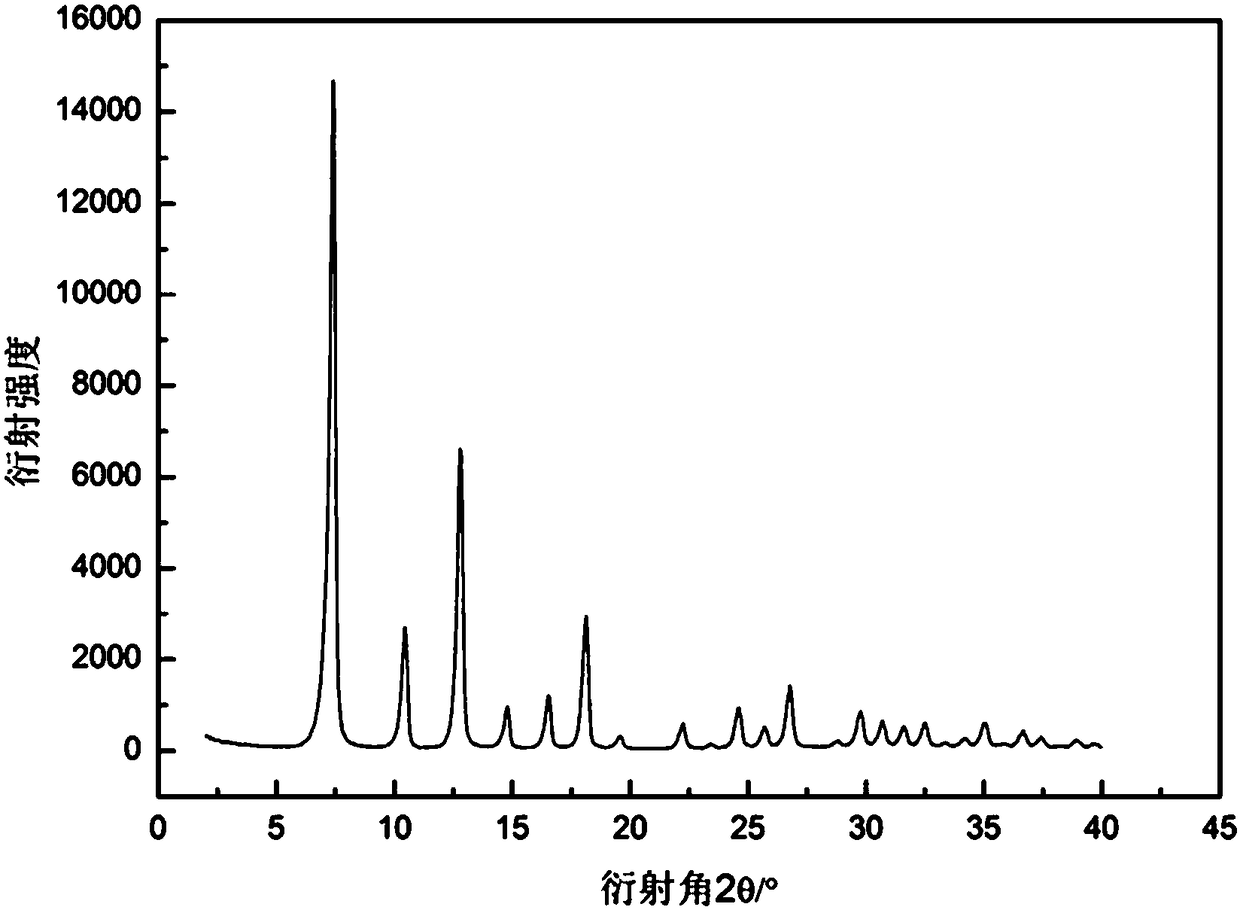

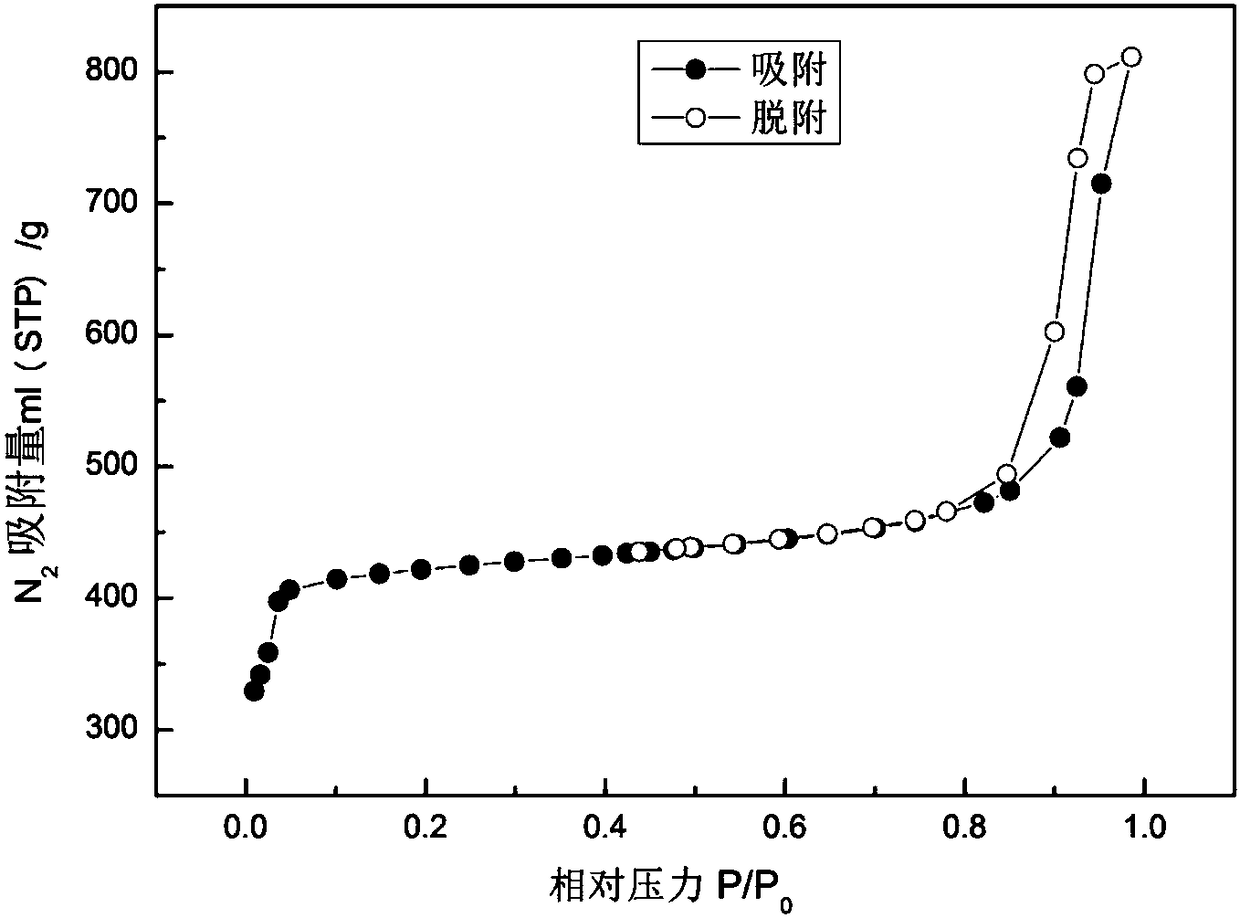

[0040] In yet another specific embodiment, ZIF-8 is used as a matrix material to prepare a ZIF-8 ...

Embodiment 1

[0048] Ionic liquid [BMIM][Tf immobilized in cages prepared by impregnation in mixed solvents at high temperature 2 N] ZIF-8 composite (composite IL 1 @ZIF-8), the specific synthesis steps are as follows:

[0049] (1) Preparation of parent material ZIF-8:

[0050] To 1.8g solid Zn(NO 3 ) 2 ·6H 2 O and 4.0g solid 2-methylimidazole (mim) mixture was added 100ml of anhydrous methanol, stirred for 30 minutes to fully dissolve the reactant and mixed uniformly, then the reaction mixture was left standing at room temperature for 24 hours. The formula for synthesizing ZIF-8 at room temperature is: Zn 2+ :xmIm:yCH 3 OH, where x is 8 and y is 400.

[0051] (2) Washing and drying of parent material ZIF-8:

[0052] The product obtained by the reaction is obtained by centrifugal separation, and ultrasonically cleaned with a large amount of anhydrous methanol three times, and the product and methanol washing solution are centrifugally separated after each ultrasonic cleaning. The r...

Embodiment 2

[0065] Immobilized ionic liquids in cages [BMIM][BF 4 ] ZIF-8 composite material, the specific synthesis steps are as follows:

[0066] (1) Preparation of parent material ZIF-8: same as step (1) in Example 1;

[0067] (2) washing and drying of parent material ZIF-8: same as step (2) in embodiment 1;

[0068] (3) Immobilized ionic liquid [BMIM][BF 4 ] ZIF-8 composite material, denoted as IL 2 @ZIF-8:

[0069] Add the dry ZIF-8 solid obtained in the above step (2) into ionic liquid [BMIM][BF 4 ] and butanol in a mixed solvent, where the ionic liquid [BMIM[BF 4 ] with butanol in a volume ratio of 8:2, and the volume fraction of butanol in the total volume is 20%, and then it is placed in a 100°C oven, the immersion temperature is 100°C, and the immersion time is 48 hours.

[0070] (4) Composite material IL 2 Drying of @ZIF-8:

[0071] The solid product obtained in step (3) is obtained by centrifugation, and ultrasonically cleaned with a large amount of anhydrous methanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com