Preparation method of heterogeneous photo-Fenton catalyzing material

A catalytic material and heterogeneous technology, applied in the direction of heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of active catalytic nanoparticles easy to agglomerate, etc., to improve the effect and overcome the pH The effect of small action range and improved electron transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

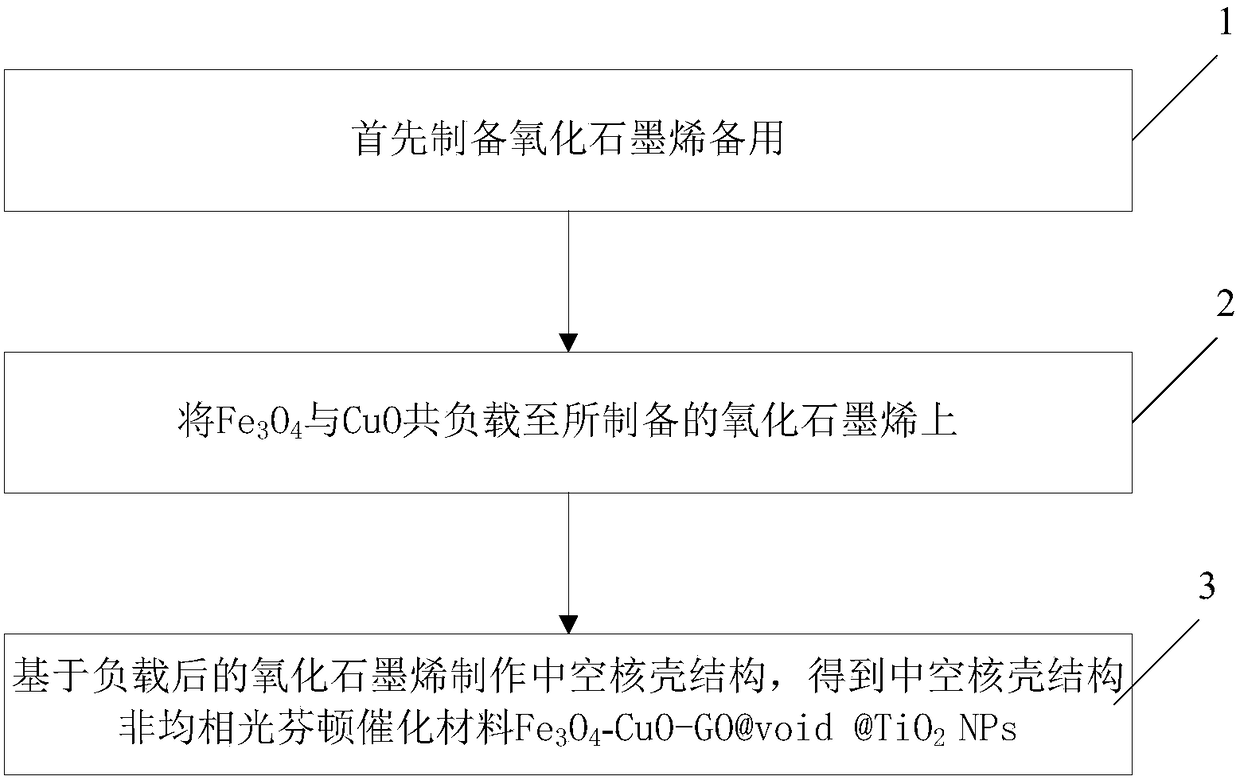

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1, the present embodiment adopts FeCl 3 ·6H 2 O, CuCl 2 2H 2 O, graphene oxide and butyl titanate (TBOT), prepare a graphene oxide-supported iron-copper double metal oxide with a loading rate of 10wt% (n(Fe):n(Cu)=4:1) and use titanium dioxide as the Hollow core-shell structure heterogeneous photo-Fenton catalyst material with shell.

[0078] The first is the preparation of graphene oxide: take 1g graphite powder and 1g NaNO 3 Put it into a 500mL three-necked flask, put it in an ice bath, and add 25mL of concentrated H 2 SO 4 . Second, slowly add 3g KMnO 4 The reaction was carried out for 2h. Afterwards, the three-necked flask was heated to 35° C. and kept for 1 h. Then slowly add 80 mL of deionized water to the reaction liquid, control the temperature of the bath liquid at about 90° C., and react for 15 min. Next, the liquid in the three-necked flask was poured into a 1000mL flask, 200mL of deionized water was added thereto, and H 2 o 2 (30wt%, >...

Embodiment 2

[0084] Embodiment 2, the present embodiment adopts FeCl 3 ·6H 2 o 2 , CuCl 2 2H 2 o 2 , graphene oxide and butyl titanate (TBOT), prepare a graphene oxide-supported iron-copper bimetallic oxide with a loading rate of 20wt% (n(Fe):n(Cu)=4:1) and use titanium dioxide as the shell Hollow core-shell structured heterogeneous photo-Fenton catalyst materials.

[0085] The first is the preparation of graphene oxide: take 1g graphite powder and 1g NaNO 3 Put it into a 500mL three-necked flask, put it in an ice bath, and add 25mL of concentrated H 2 SO 4 . Second, slowly add 3g KMnO 4 The reaction was carried out for 2h. Afterwards, the three-necked flask was heated to 35° C. and kept for 1 h. Then slowly add 80 mL of deionized water to the reaction liquid, control the temperature of the bath liquid at about 90° C., and react for 15 min. Next, the liquid in the three-necked flask was poured into a 1000mL flask, 200mL of deionized water was added thereto, and H 2 o 2 (30wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com