Electrostatic spraying paint for heat dissipation of casing of electric appliance

A technology of electrostatic spraying and electrical casing, applied in the field of coatings, can solve problems such as incompatibility with polymers, difficulty in dispersing graphene, and restrictions on the application of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

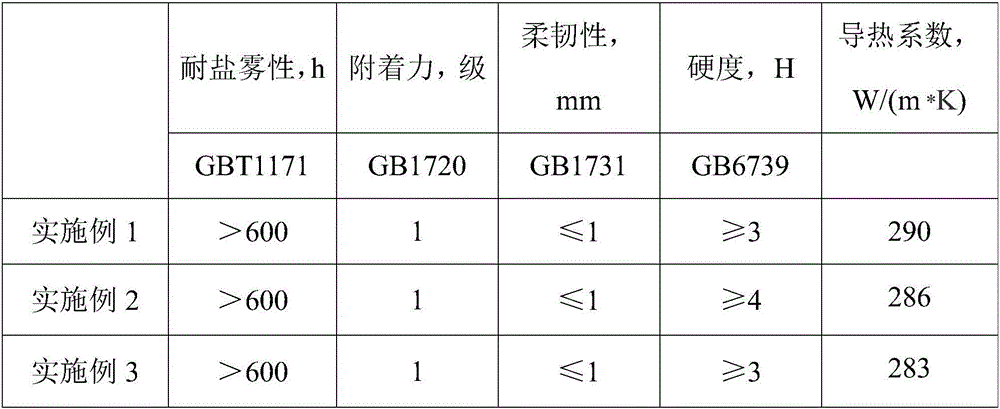

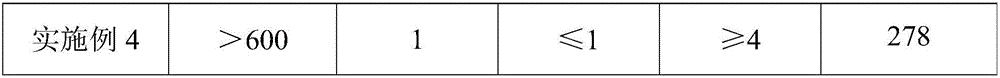

Examples

Embodiment 1

[0018] An electrostatic spray coating for heat dissipation of an electrical shell, the raw materials of which include by weight: 55 parts of polyester resin, 15 parts of bisphenol A epoxy resin, 5 parts of modified graphene, 3 parts of titanium dioxide, 0.5 parts of polyaniline, mica 10 parts of iron oxide, 10 parts of titanium dioxide, 10 parts of mica powder, 1 part of zeolite powder, 25 parts of precipitated barium sulfate, 1 part of carbon black, 2 parts of polyacrylate polymer, 1 part of polyacrylate leveling agent, fat 15 parts of amine curing agent, 10 parts of methyl isobutyl ketone;

[0019] The method for preparing the modified graphene comprises: adding 1 part of graphene oxide into a solvent of 500 parts of water and ethanol by weight for ultrasonic dispersion for 0.5 h, the power of ultrasonic dispersion is 5000w, the frequency is 10000Hz, and the temperature is 60°C. To obtain a graphene oxide solution, add 1 part of polyester resin prepolymer to continue ultraso...

Embodiment 2

[0021] An electrostatic spray coating for heat dissipation of an electrical shell, the raw materials of which include by weight: 85 parts of polyester resin, 5 parts of bisphenol F epoxy resin, 15 parts of modified graphene, 1 part of titanium dioxide, 2 parts of polyaniline, pigment 3 parts, 30 parts of titanium dioxide, 5 parts of mica powder, 5 parts of zeolite powder, 5 parts of precipitated barium sulfate, 5 parts of carbon black, 0.5 parts of polymer silicone, polystyrene / maleic acid leveling agent 3 parts, 5 parts of aromatic amine curing agent, 30 parts of solvent;

[0022] The method for preparing the modified graphene comprises: adding 10 parts of graphene oxide into 100 parts of methyl acetate by weight for ultrasonic dispersion for 2 hours, the power of ultrasonic dispersion is 1000w, the frequency is 100000Hz, and the temperature is 40°C to obtain graphite oxide Then add 100 parts of polyester resin prepolymer and continue ultrasonic dispersion for 0.5h. After hea...

Embodiment 3

[0025] An electrostatic spray coating for heat dissipation of an electrical appliance shell, the raw materials of which include by weight: 65 parts of polyester resin, 12 parts of bisphenol A epoxy resin, 8 parts of modified graphene, 2.5 parts of titanium dioxide, 0.8 parts of polyaniline, phosphoric acid 8 parts of zinc, 15 parts of titanium dioxide, 8 parts of mica powder, 2 parts of zeolite powder, 20 parts of precipitated barium sulfate, 2 parts of carbon black, 1.5 parts of fluorine-modified acrylate polymer, polyisobutylene / maleic acid salts 1 part of leveling agent, 12 parts of alicyclic amine curing agent, 15 parts of n-butanol;

[0026] The method for preparing the modified graphene comprises: adding 5 parts of graphene oxide into 300 parts of toluene in parts by weight for ultrasonic dispersion for 1.5 hours, the power of ultrasonic dispersion is 3000w, the frequency is 50000Hz, and the temperature is 50°C to obtain graphene oxide Solution, then add 50 parts of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com