Preparation method for spherical-graphene lubricant additive and use of spherical-graphene lubricant additive

A technology of lubricating additives and spherical graphite, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of chemical reagent volatilization environment, pollution, affecting the tribological properties of graphene, etc. The effect of elastic deformation ability, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

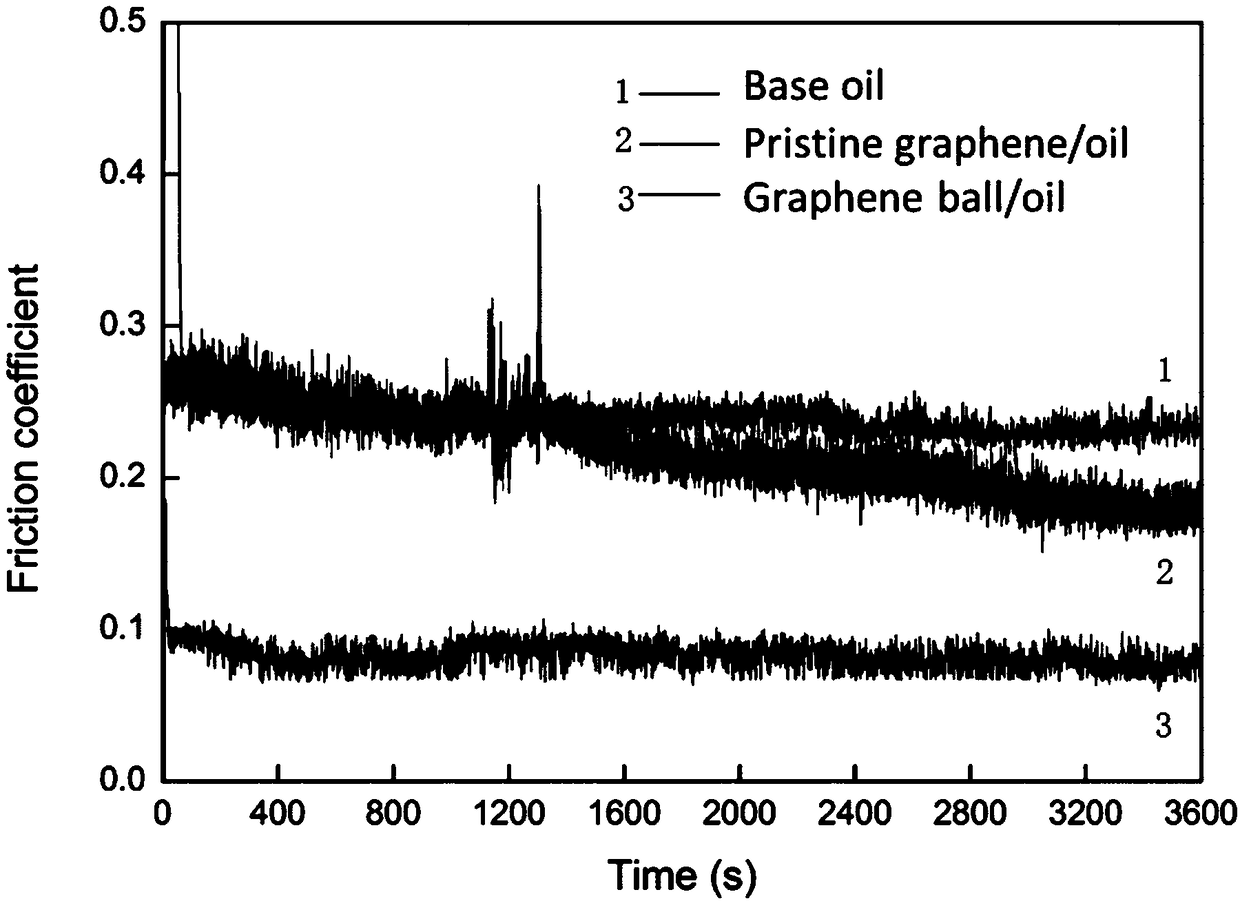

Image

Examples

Embodiment 1

[0038] In this embodiment, the specific process and process parameters for the preparation of spherical graphene lubricating additives are:

[0039] (1) Graphene prepared by redox method was selected as raw material, and pulverized by a universal mechanical pulverizer with a rotating speed of 9000rpm and a processing time of 60min. The pulverized graphene was dispersed into water at a concentration of 2 mg / ml, and the graphene solution was ultrasonically dispersed and pulverized using a cell crushing ultrasonic machine with an operating power of 1000 W and a time of 120 min. The ultrasonic solution was subjected to centrifugation treatment, the centrifuge speed was 9000rpm, and the working time was 30min, and the graphene solution whose sheet size after separation was between 8 and 15 μm was selected.

[0040] (2) carry out surfactant modification water dispersion treatment to above-mentioned graphene solution system, choose polyvinylpyrrolidone (PVP) to join in the graphene s...

Embodiment 2

[0045] The difference from Example 1 is that in the present embodiment, the specific process and process parameters for the preparation of spherical graphene lubricating additives are:

[0046] (1) Graphene prepared by redox method was selected as raw material, and pulverized by a universal mechanical pulverizer with a rotating speed of 10000rpm and a processing time of 45min. The pulverized graphene was dispersed into water with a concentration of 4 mg / ml, and the graphene solution was ultrasonically dispersed and pulverized using a cell crushing ultrasonic machine with an operating power of 1200 W and a time of 150 min. The ultrasonic solution was subjected to centrifugation treatment, the centrifuge speed was 9000rpm, and the working time was 60min, and the graphene solution whose sheet size after separation was between 10 and 12 μm was selected.

[0047] (2) carry out surfactant modified water dispersion treatment to above-mentioned graphene solution system, choose PVP to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com