A low-temperature drift oscillator and method for obtaining low-temperature drift clock frequency

A clock frequency and low-temperature drift technology, which is applied in the field of low-temperature drift oscillators and low-temperature drift clock frequency, can solve problems such as poor product consistency, high process consistency requirements, and impact on oscillator frequency temperature drift, etc., to achieve high power supply suppression Ratio, wide adjustable range, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

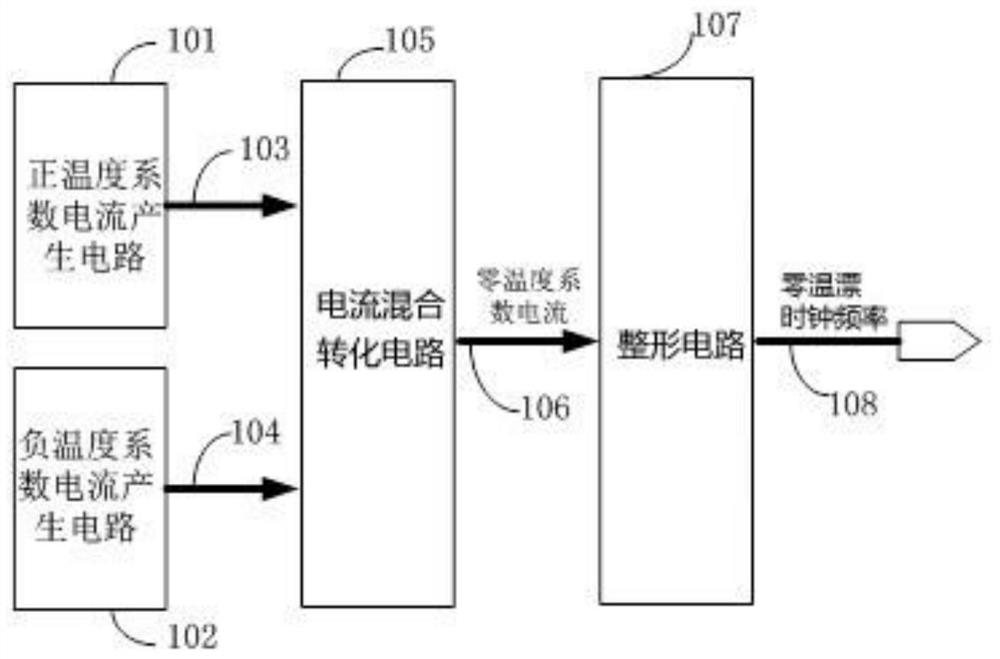

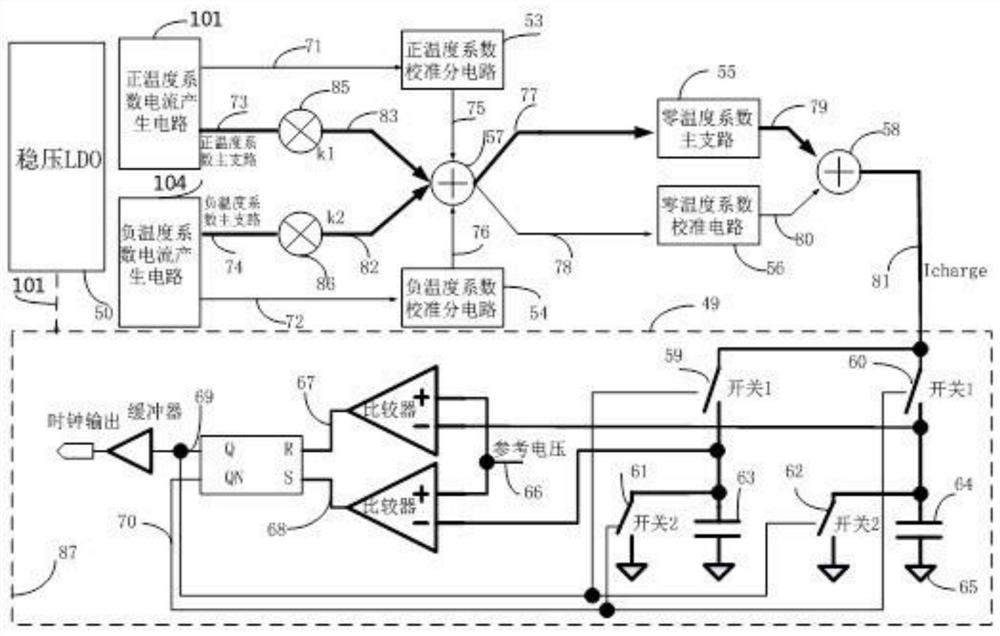

[0024] Such as figure 1 As shown, a low-temperature drift oscillator includes a positive temperature coefficient current generating circuit 101, a negative temperature coefficient current generating circuit 102, a current mixing conversion circuit 105 and a capacitance shaping circuit 107, and the positive temperature coefficient current generating circuit 101 generates a current mirror through a current mirror. The positive temperature coefficient main branch 73 and a positive temperature current calibration branch 71, the negative temperature coefficient current generation circuit 102 produces a negative temperature coefficient main branch 74 and a negative temperature current calibration branch 71 through the current mirror; the positive temperature coefficient main Branch 73, positive temperature and current calibration branch 71, negative temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com