Mirror image milling follow-up jacking support device and method for thin-walled parts

A technology of mirror milling and thin-walled parts, which is used in positioning devices, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of workpiece machining chatter and local deformation, and achieve the effect of reducing investment and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] For the following examples see Figure 1-6 .

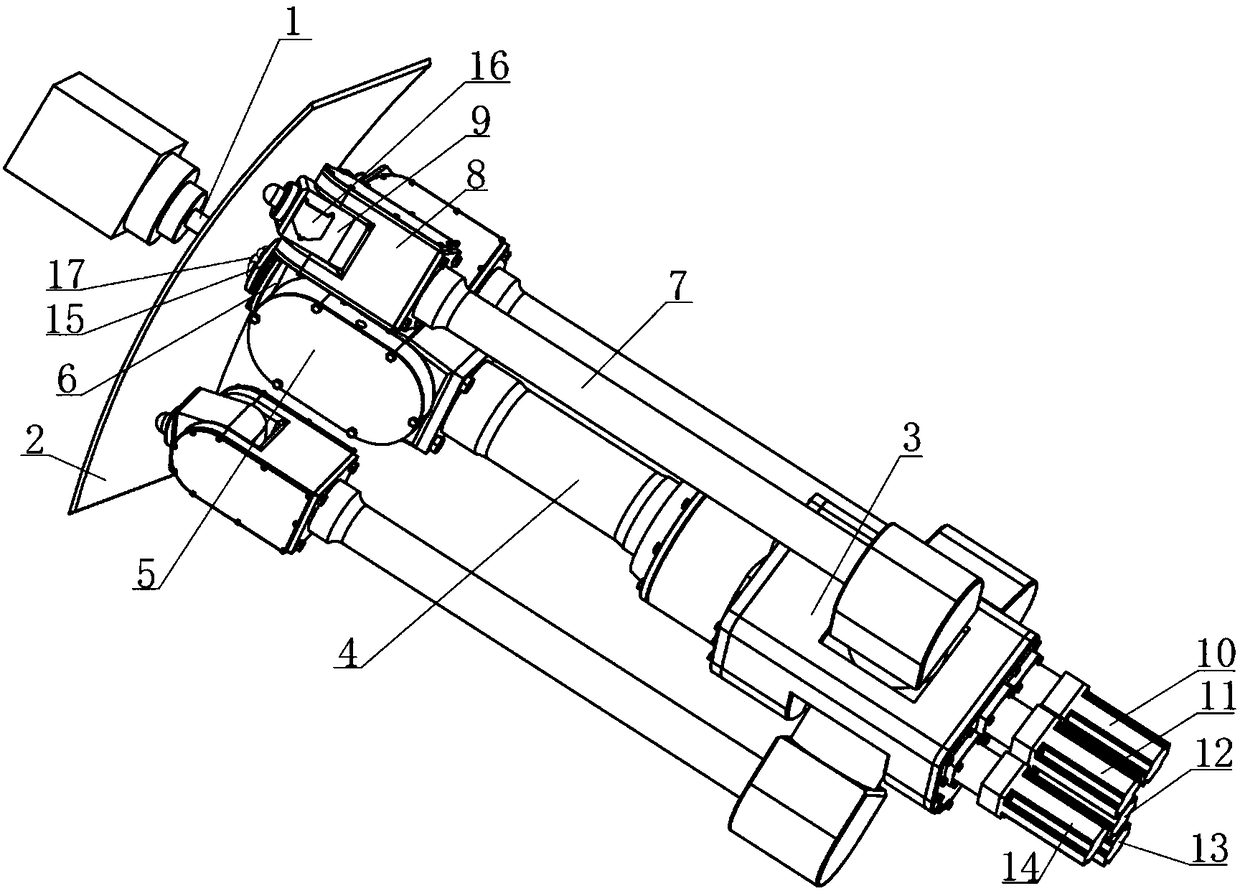

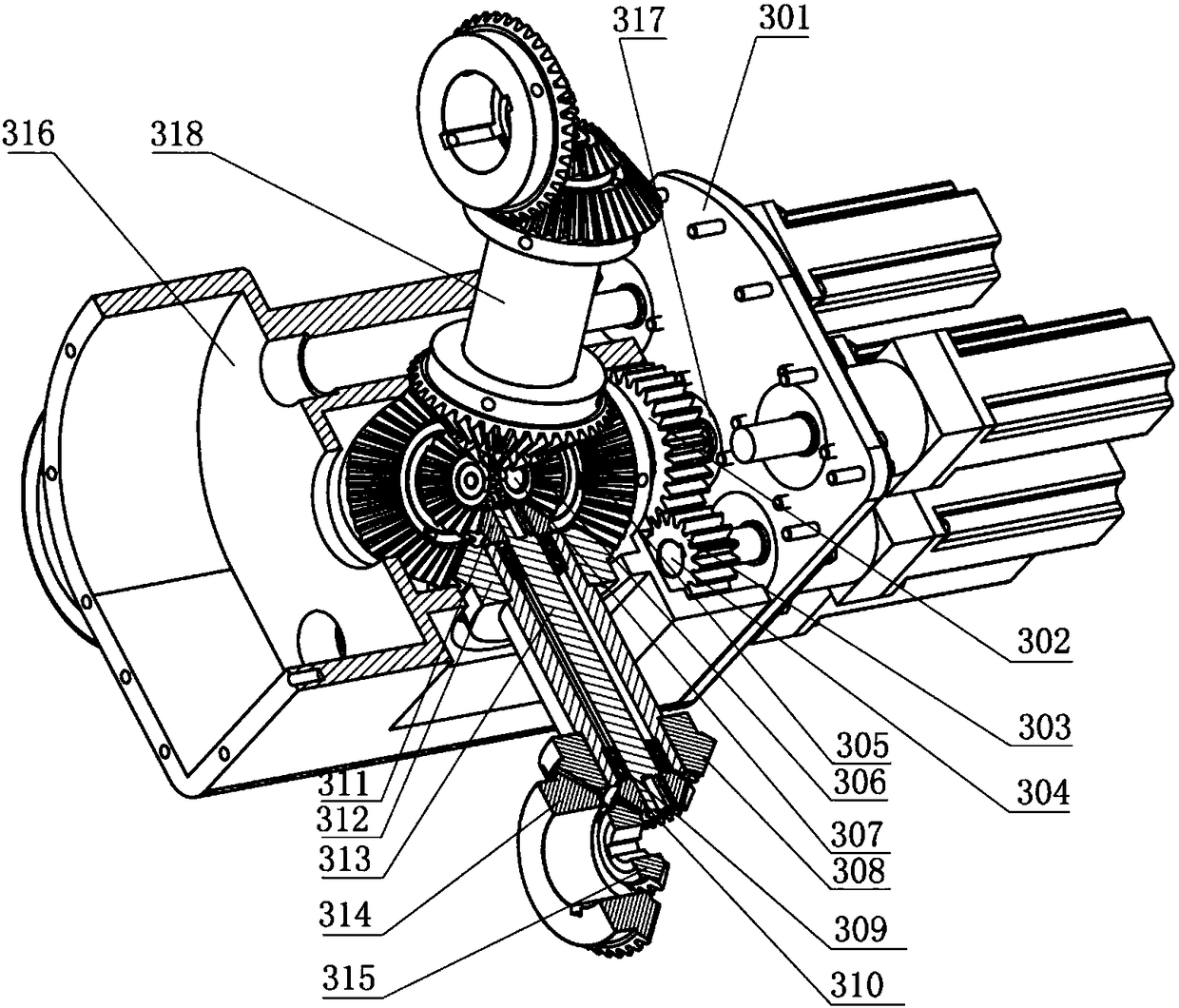

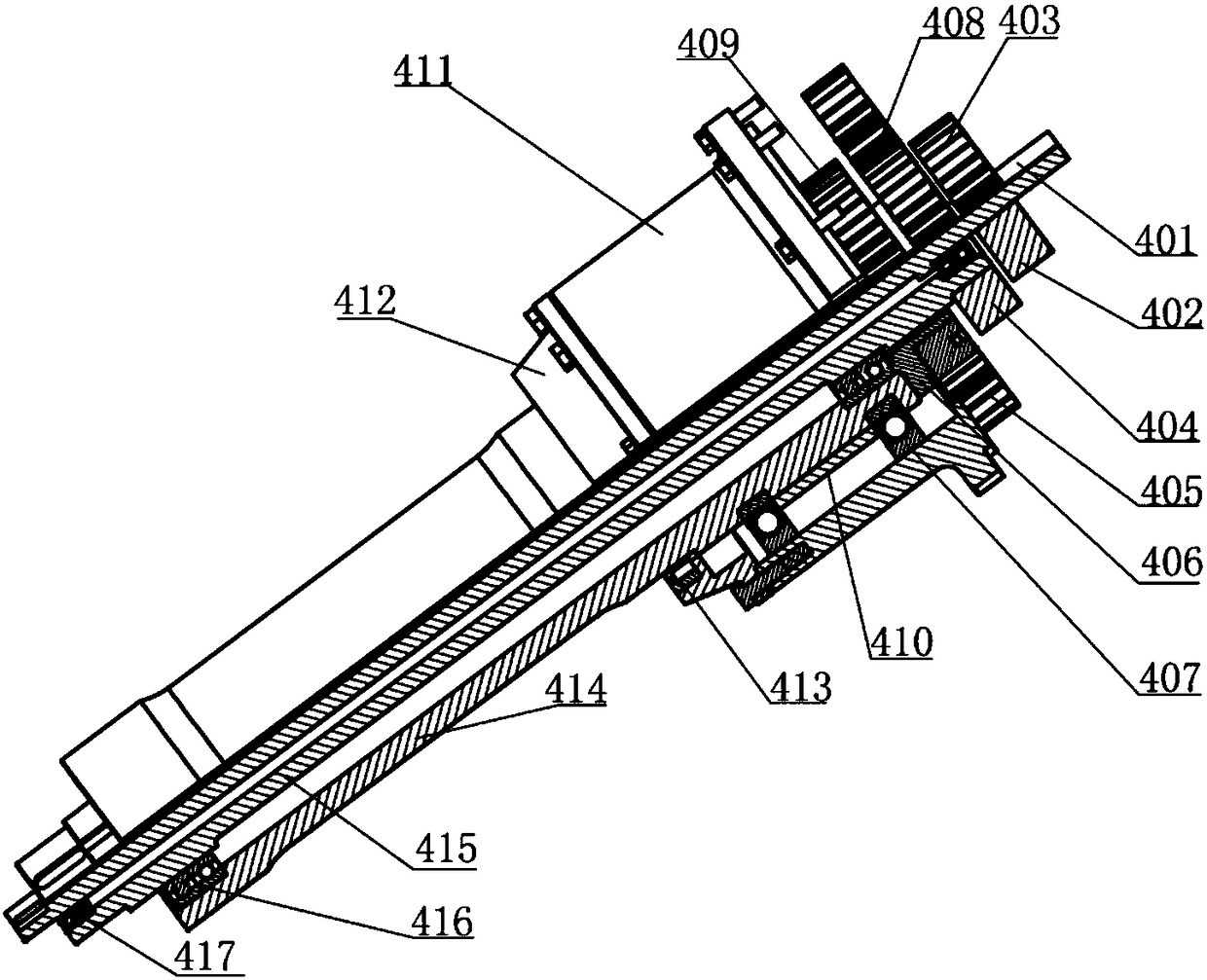

[0031] The follow-up supporting device for mirror milling of thin-walled parts in this embodiment includes the main supporting head 6, the supporting arm rotating box 3, the main supporting arm 4, the supporting head rotating box 5, the auxiliary supporting arm 7, the auxiliary supporting arm Jacking head rotating box 8, auxiliary jacking head 9, first servo motor 10, second servo motor 14, third servo motor 13, fourth servo motor 11, fifth servo motor 12, pressure sensor 15, laser sensor 16 , thickness gauge 17, such as figure 1 shown.

[0032] The follow-up supporting device for mirror milling of thin-walled parts is realized by controlling 5 high-precision servo motors through an industrial computer and a motion control card, and driven by spur gears and bevel gears. like Figure 4 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com