Vertical continuous plating (VCP) high TP value acidic copper plating gloss agent and preparation method and application thereof

A technology of vertical continuous electroplating and acid copper plating, which is applied in the field of acid copper plating chemical solution for printed circuit boards, can solve the problems that the performance and function cannot keep up with the needs of cutting-edge technological innovation, increase the risk of production control, abnormal technical indicators, etc., and achieve Convenient application, stable product quality, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

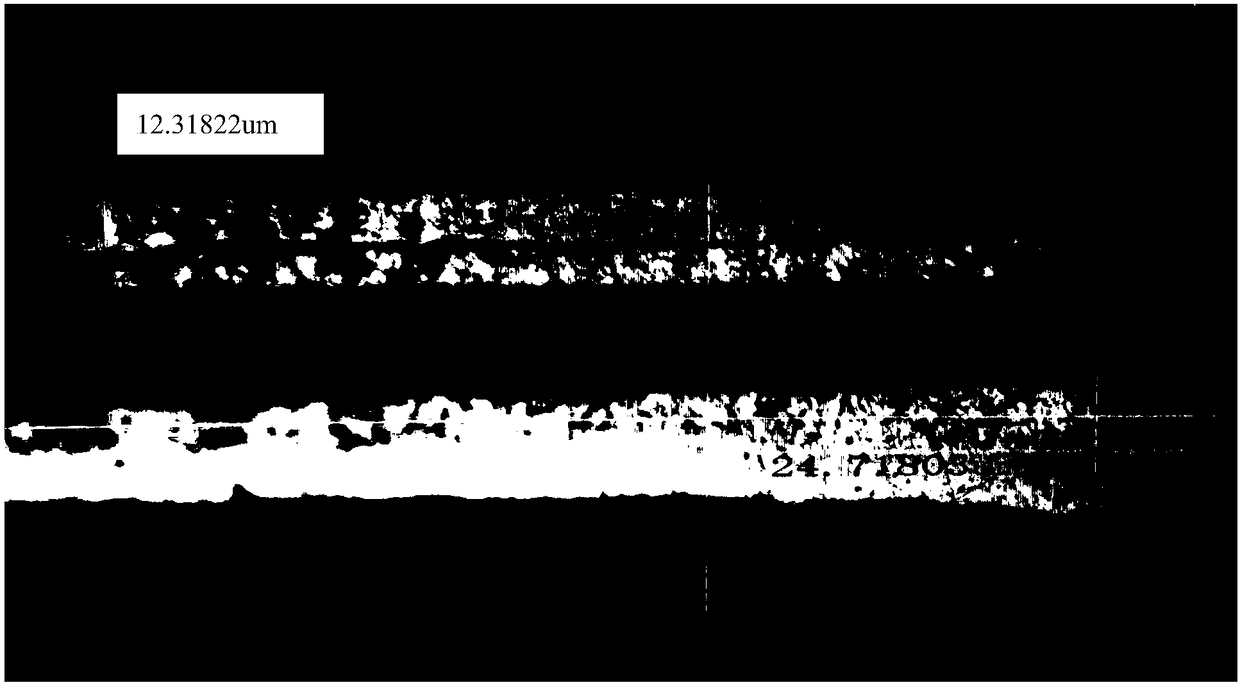

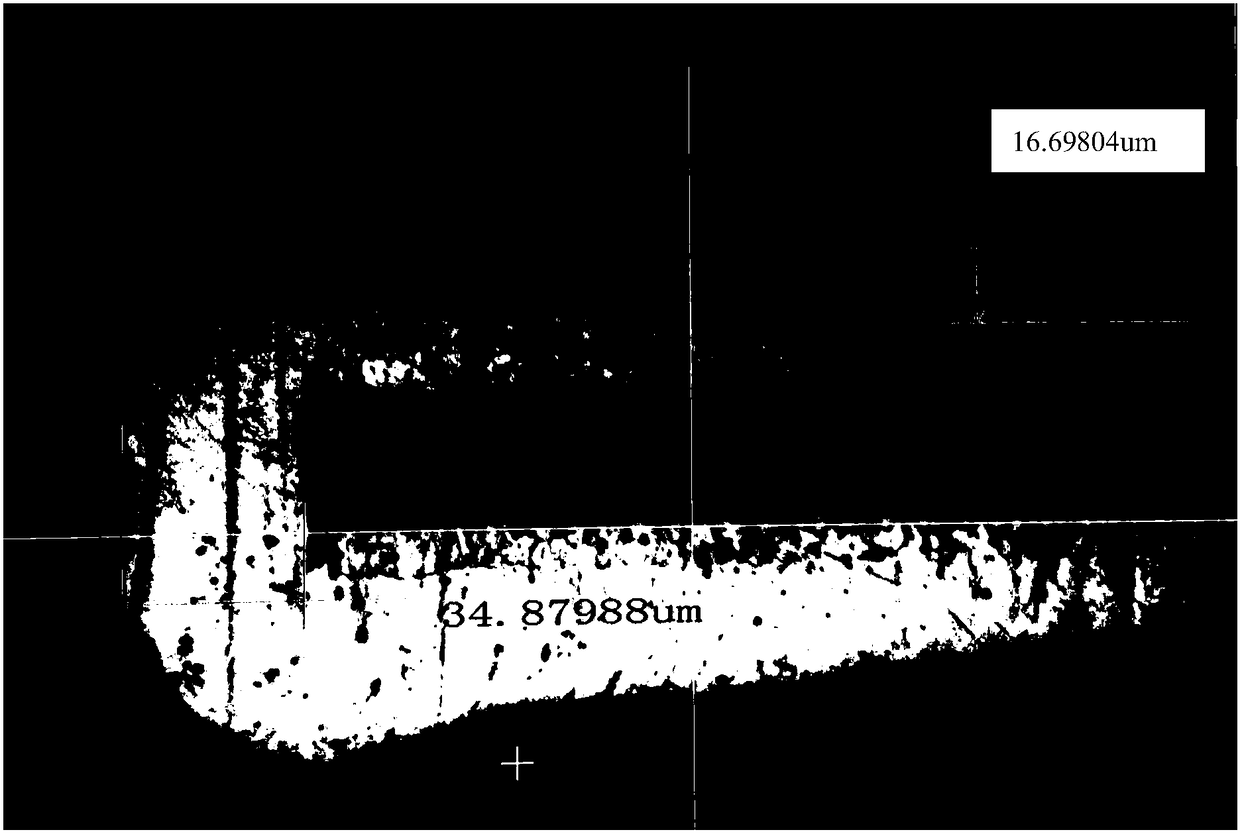

Image

Examples

Embodiment 1

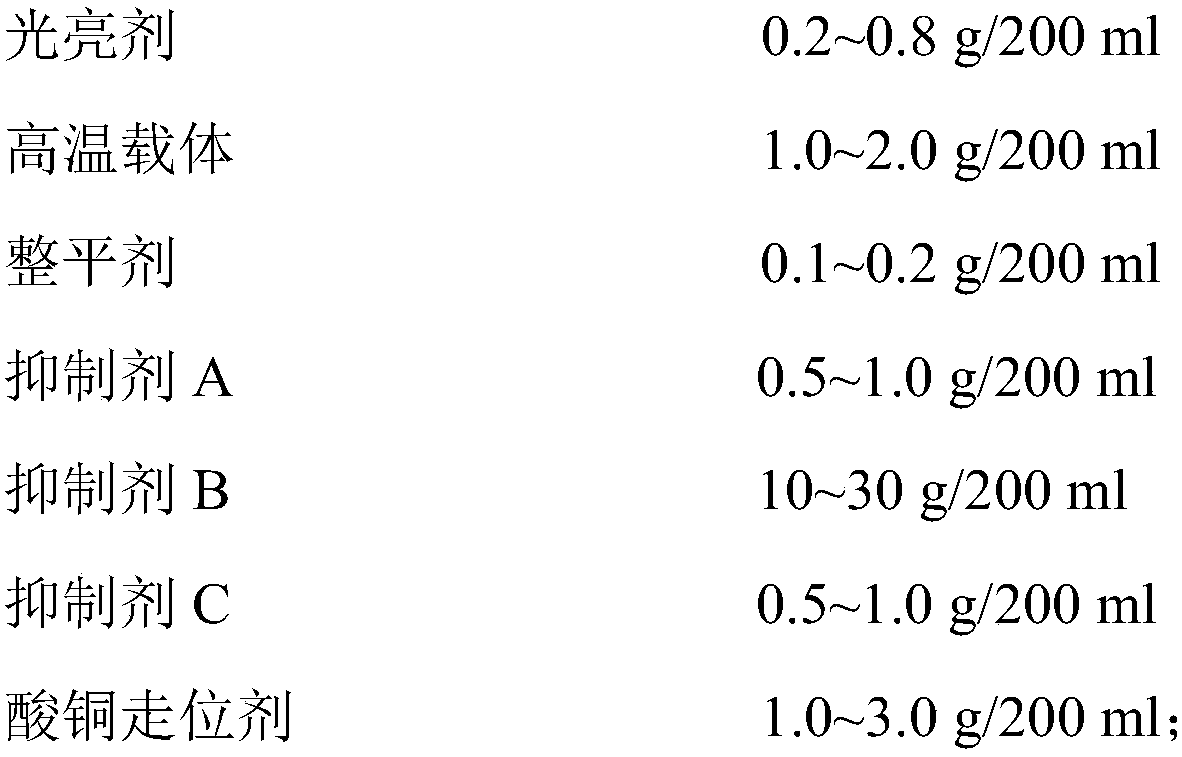

[0035] A kind of vertical continuous electroplating (VCP) high TP value acid copper plating gloss agent, comprises the component of following content:

[0036]

[0037]According to the above formula, weigh 0.5 g of sodium thiazoline-based dithiopropane sulfonate, 1.5 g of polyethyleneimine alkyl salt, 0.5 g of fatty amine polyoxyethylene ether, polyethylene oxide polypropylene oxide monobutyl ether 20g, fatty amine ethoxy sulfonate 1.0g, displacer SLP 2.0g, nitro blue tetrazolium chloride 0.2g, dissolve each raw material component in an appropriate amount of deionized water and mix well, then add deionized Water is adjusted to 200ml, promptly obtains described vertical continuous electroplating (VCP) high TP value acidic copper plating gloss agent, is a kind of brown transparent liquid.

Embodiment 2

[0039] A kind of vertical continuous electroplating (VCP) high TP value acid copper plating gloss agent, comprises the component of following content:

[0040]

[0041]

[0042] The preparation steps are the same as in Example 1. The obtained product is a brown transparent liquid.

Embodiment 3

[0044] A kind of vertical continuous electroplating (VCP) high TP value acid copper plating gloss agent, comprises the component of following content:

[0045]

[0046] The preparation steps are the same as in Example 1. The obtained product is a brown transparent liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com