Molding sand regeneration method and regenerating system

A regeneration system and molding sand technology, applied in chemical instruments and methods, machinery for cleaning/processing casting materials, casting molding equipment, etc., can solve the problem of low strength of chemical bonding binders, weak magnetism, and castings Calcination defects and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the best mode for carrying out the present invention will be described.

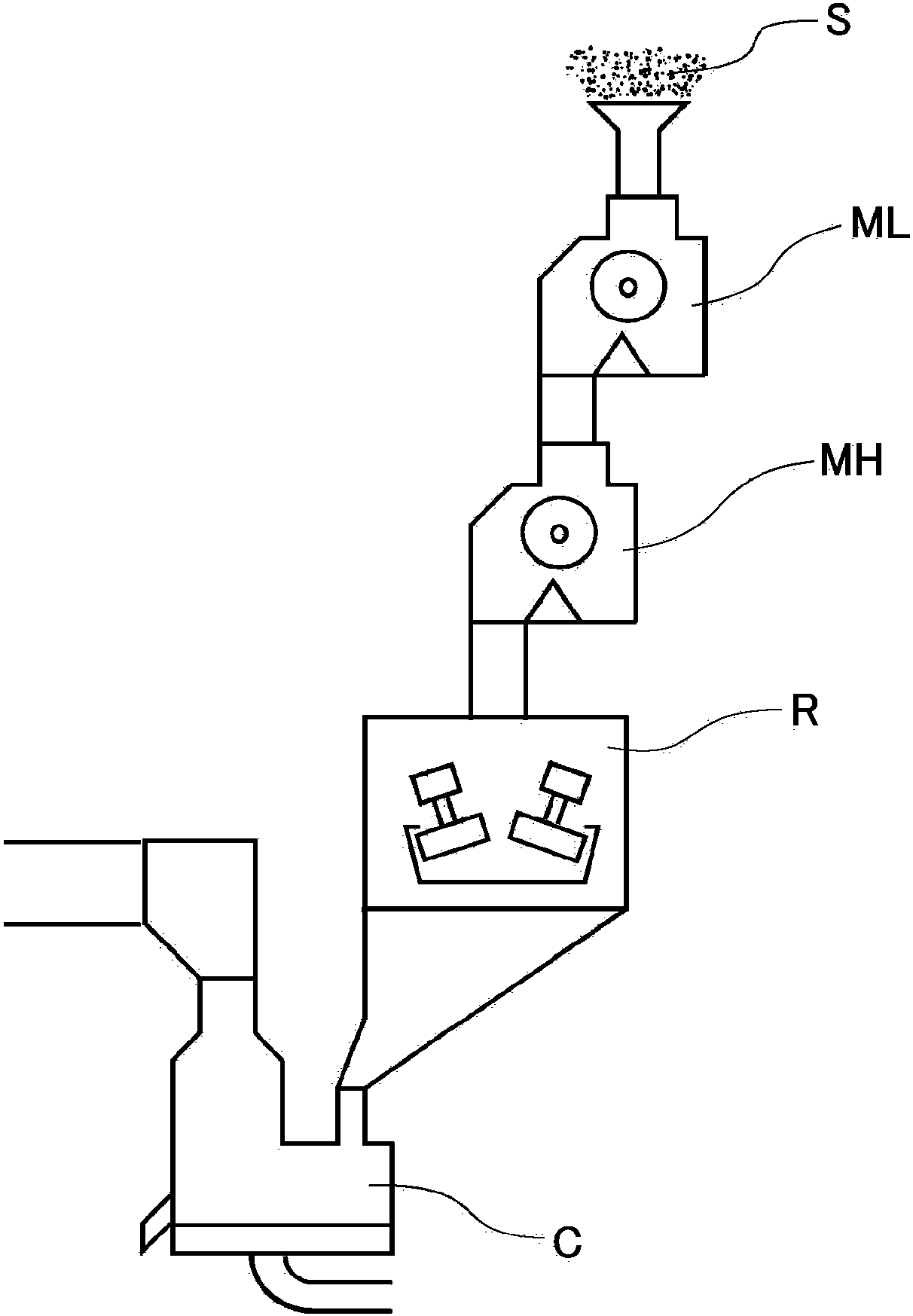

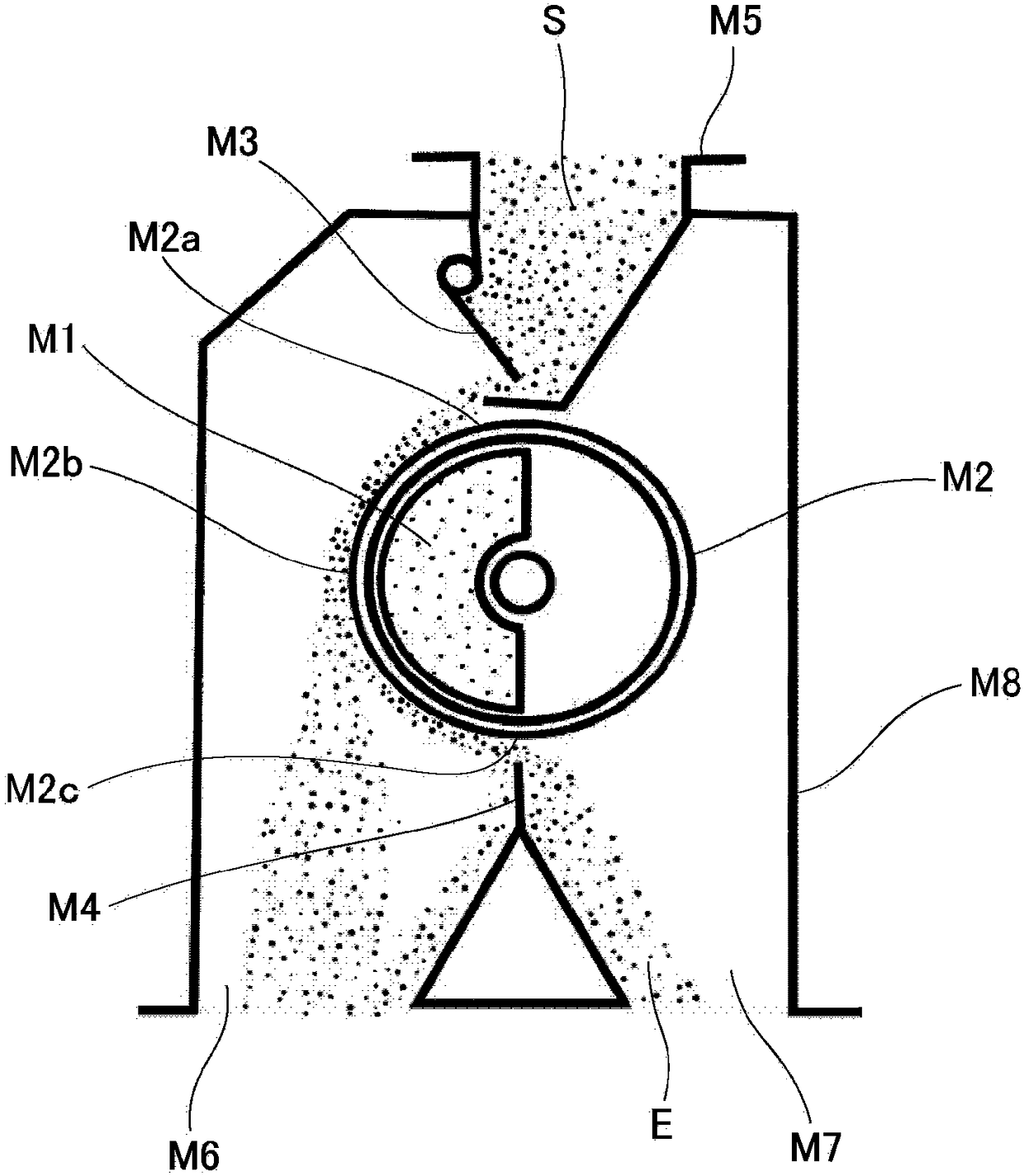

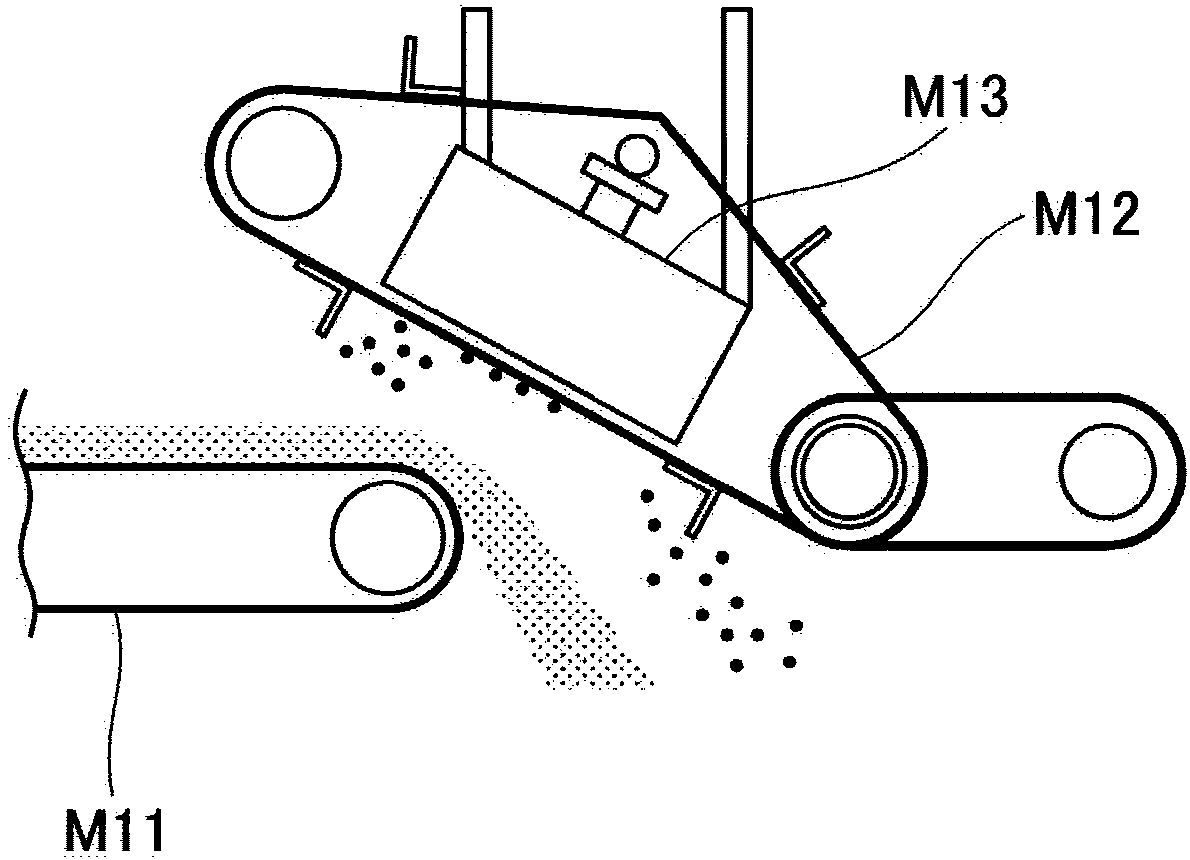

[0039] First, a method for regenerating molding sand will be described. The method for regenerating mold sand is characterized in that it includes: using the mold sand separated from the casting by shot blasting as an object, using magnetic separation with a first magnetic flux density to remove metal powder and metal flakes, and using the above-mentioned first magnetic flux density Magnetic separation with a higher second magnetic flux density removes magnetized substances; and dry mechanical regeneration removes carbide-containing substances adhering to the surface from the above-mentioned mold sand.

[0040] The above-mentioned substances containing carbides refer to: in the green sand method, carbides containing porous layers called oolitics produced by sintering bentonite and additives such as coal powder or starch, etc. In the knotting process, carbides and reaction products of the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com