Processes and systems for purification of 1,3-butadiene

A technology of butadiene and butene, applied in the field of purifying 1,3-butadiene, which can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The following non-limiting examples are included purely by way of illustration of the presently disclosed subject matter. The following example is using ASPEN Results of steady-state computer simulations performed for versions 2006.5 and V8.2.

[0042] Example 1 - Parameters within an exemplary system

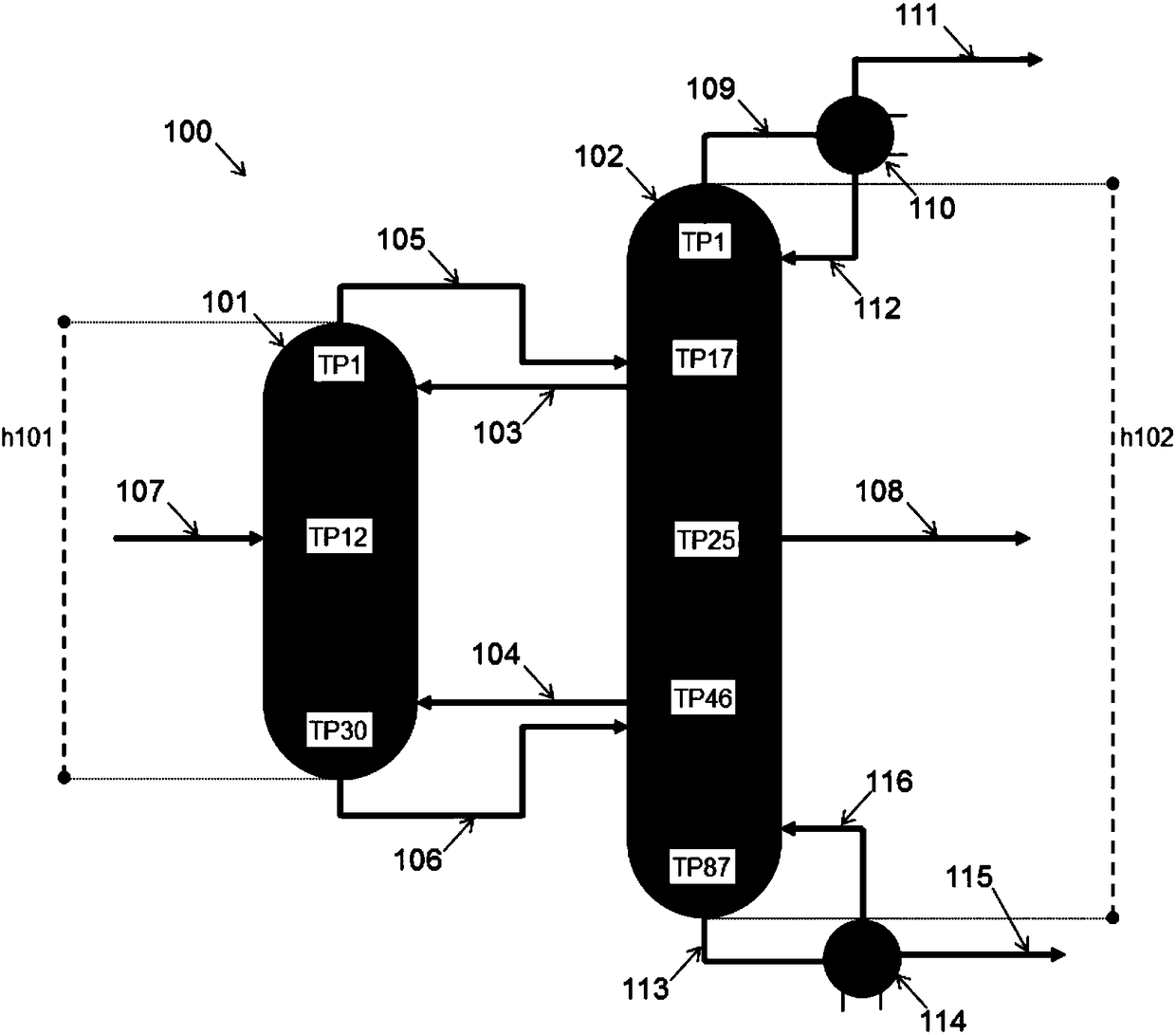

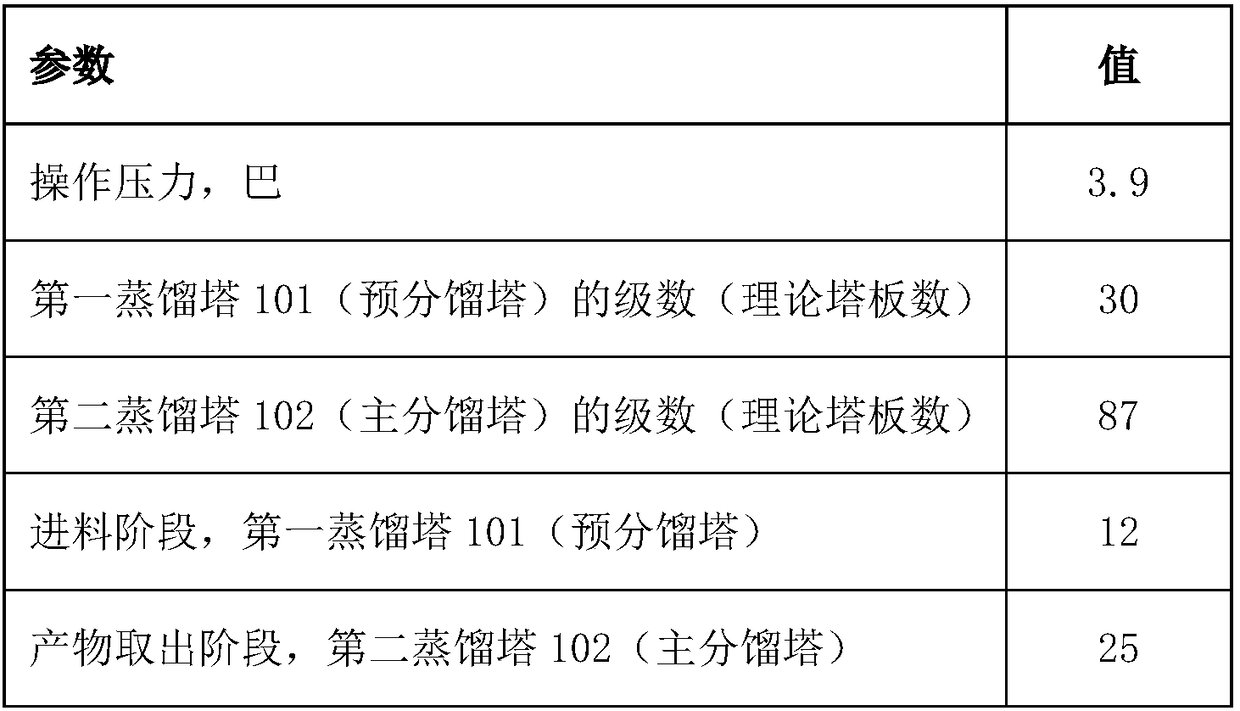

[0043] provided the basis figure 1 system 100 . The parameters of the system 100 are shown in Table 1.

[0044] Table 1

[0045]

[0046]

[0047] The reboiler duty and condenser duty values in Table 1 measure the energy input to the second distillation column 102 (main distillation column). These values demonstrate that systems and methods in accordance with the presently disclosed subject matter can be energy efficient.

Embodiment 2

[0048] Embodiment 2 - the method for purifying 1,3-butadiene

[0049] according to figure 1 A crude 1,3-butadiene stream of 15750 kg / h is fed into the system 100 . The crude 1,3-butadiene stream had the composition shown in Table 2.

[0050] Table 2

[0051]

[0052]

[0053] Crude 1,3-butadiene was supplied in liquid form to the twelfth theoretical plate of the first distillation column 101 having 30 theoretical plates via the 1,3-butadiene feed line 107 . The top vapor stream of the first distillation column 101 is fed into the seventeenth theoretical stage of the second distillation column 102 via the third interconnection 105 . The bottoms stream of the first distillation column 101 is fed into the forty-sixth theoretical plate of the second distillation column 102 via the fourth interconnection 106 . A part of the liquid reflux from the second distillation column 102 is taken from the seventeenth theoretical stage and fed to the first theoretical stage of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com