Organic film cmp slurry composition and polishing method using same

A technology of organic membranes and components, applied in chemical instruments and methods, other chemical processes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

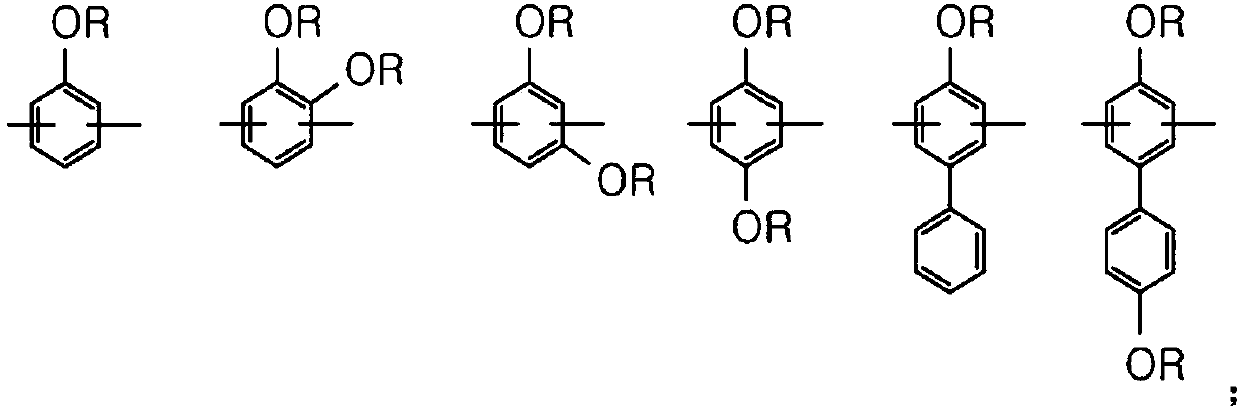

[0182] Preparation of organic film composition

[0183] A 2,000 ml 3-neck flask including a thermometer, condenser, mechanical stirrer and dropping funnel was immersed in an oil bath at 140°C. Heating and stirring were performed on a hot plate by a magnet, and the temperature of cooling water in the condenser was set to 40°C. 220 grams of 1.0 moles of 1-methoxypyrene and 138 grams of 1.0 moles of 1,4-bismethoxymethylbenzene were added to the reactor, and then dissolved in 656 grams of propylene glycol monomethyl ether acetate. Thereafter, 4.6 grams of 0.03 molar diethyl sulfate were added to the reactor. The temperature of the reactor was maintained at 130°C. The reaction completion point is determined by measuring the molecular weight of the reaction product at regular time intervals during the polymerization. Here, a sample for measuring the molecular weight was prepared by quenching 1 g of the reaction product to room temperature, and then diluting 0.02 g of the reacti...

example 1 to example 2 and comparative example 1 to comparative example 4

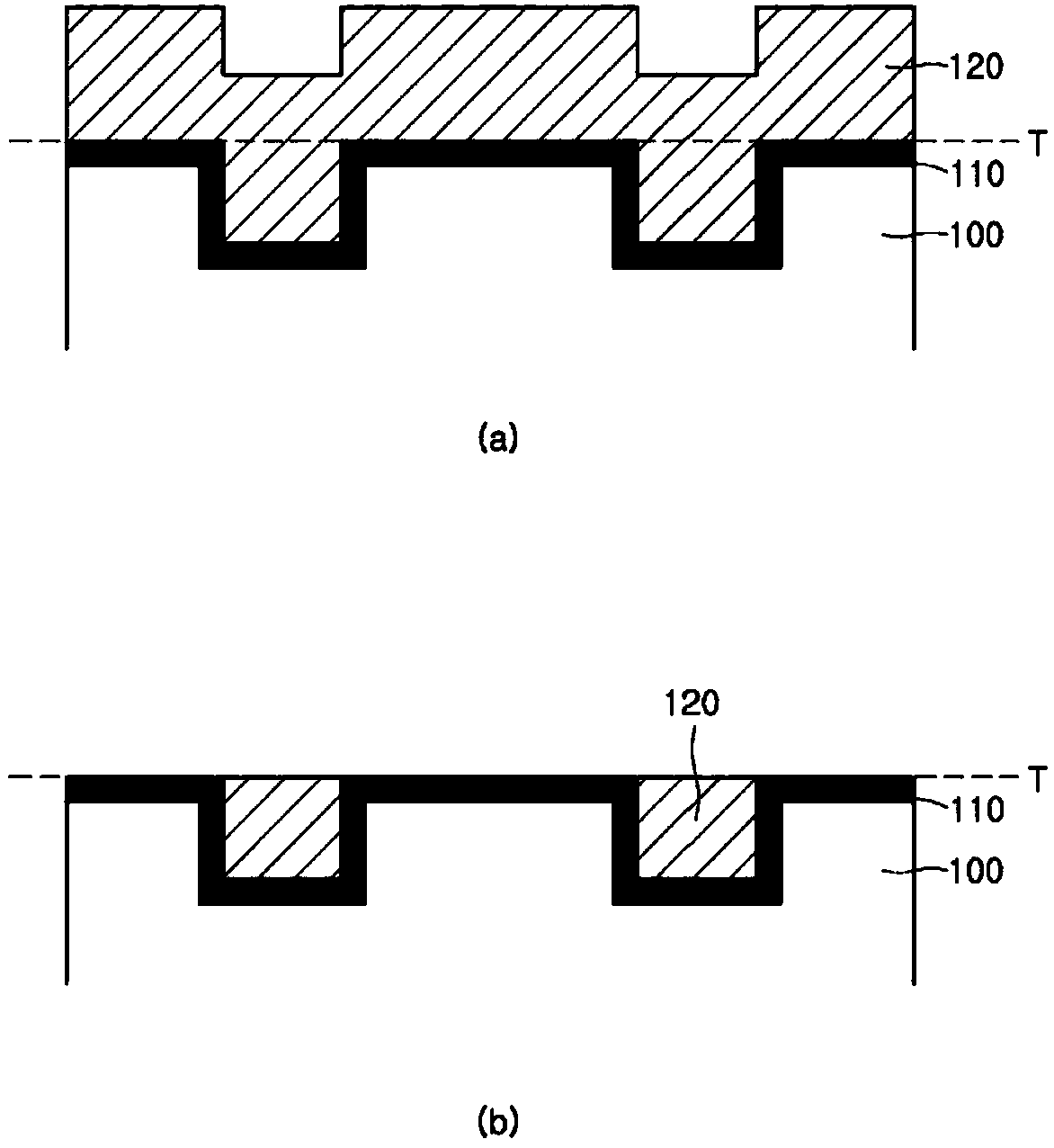

[0193] A CMP slurry composition (unit: weight % based on the total amount of the composition) comprising the components listed in Table 1 was prepared, and the patterned crystal comprising a silicon oxide layer and an organic film was prepared under the following conditions: circle for grinding.

[0194] (1) Details of the components of the CMP slurry composition

[0195] (A) abrasive

[0196] (a1) Colloidal cerium oxide (SOLVAY Co., Ltd.) having an average particle diameter of 60 nm was used.

[0197] (a2) Colloidal cerium oxide (FUSO Co., Ltd.) having an average particle diameter of 30 nm was used.

[0198] (B) reducing agent

[0199] (b1) Cerium nitrate (Aldrich Co., Ltd.) was used.

[0200] (b2) Titanium trichloride (KANTO Co., Ltd.) was used.

[0201] (C) pH adjuster: nitric acid (Samchun Chemical Co., Ltd.) was used.

[0202] (2) Grinding conditions and measurement of grinding rate and selectivity ratio

[0203] As a polishing pad, an H0800CMP pad (FUJIBO Co.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com