Environment-friendly energy-saving efficient smokeless barbecue oven utilization method

An environment-friendly, energy-saving, barbecue stove technology, applied in the field of barbecue stoves, can solve problems such as the influence of smoke and dust on operators, difficulty in ignition, heat loss, etc., and achieve the effects of convenient and simple ignition of charcoal, improved barbecue comfort, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

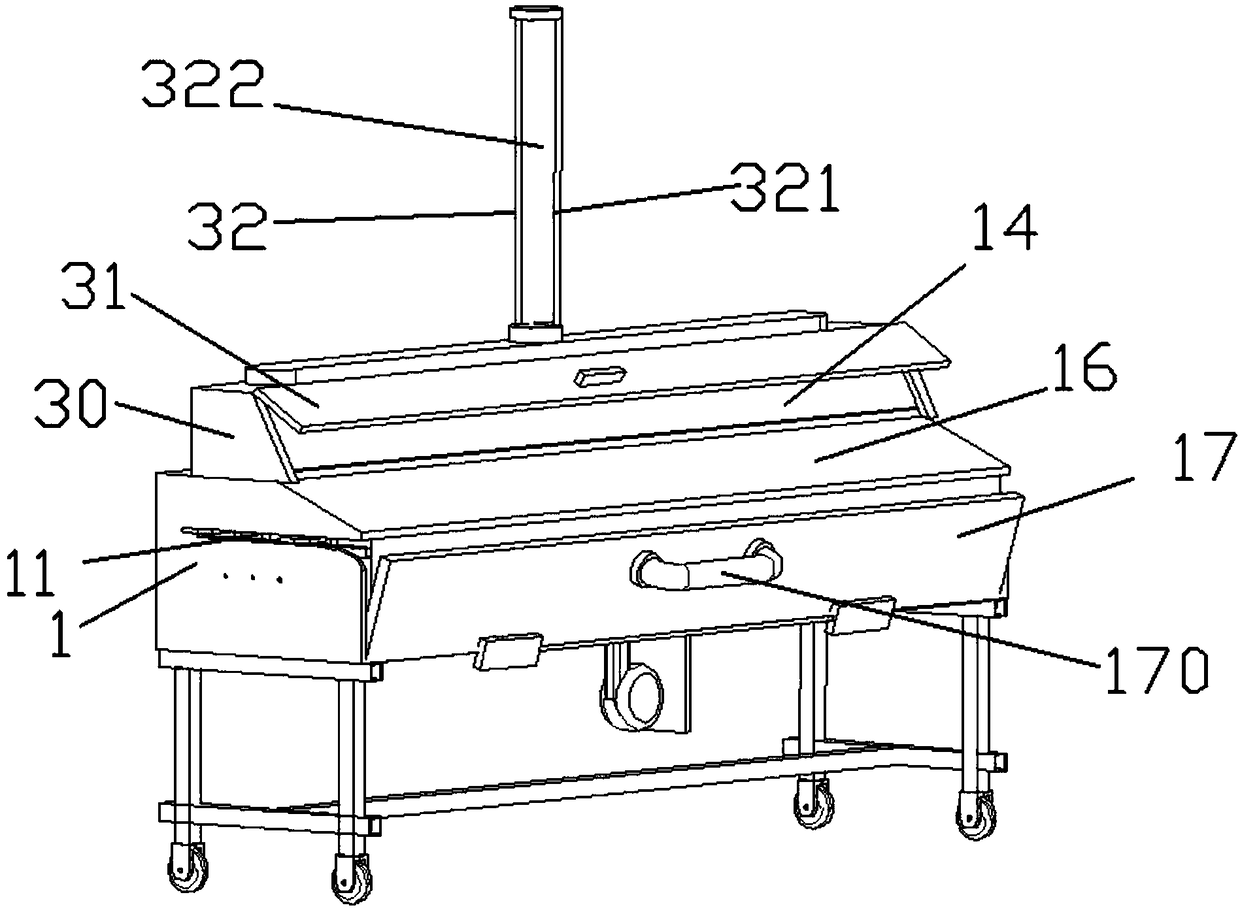

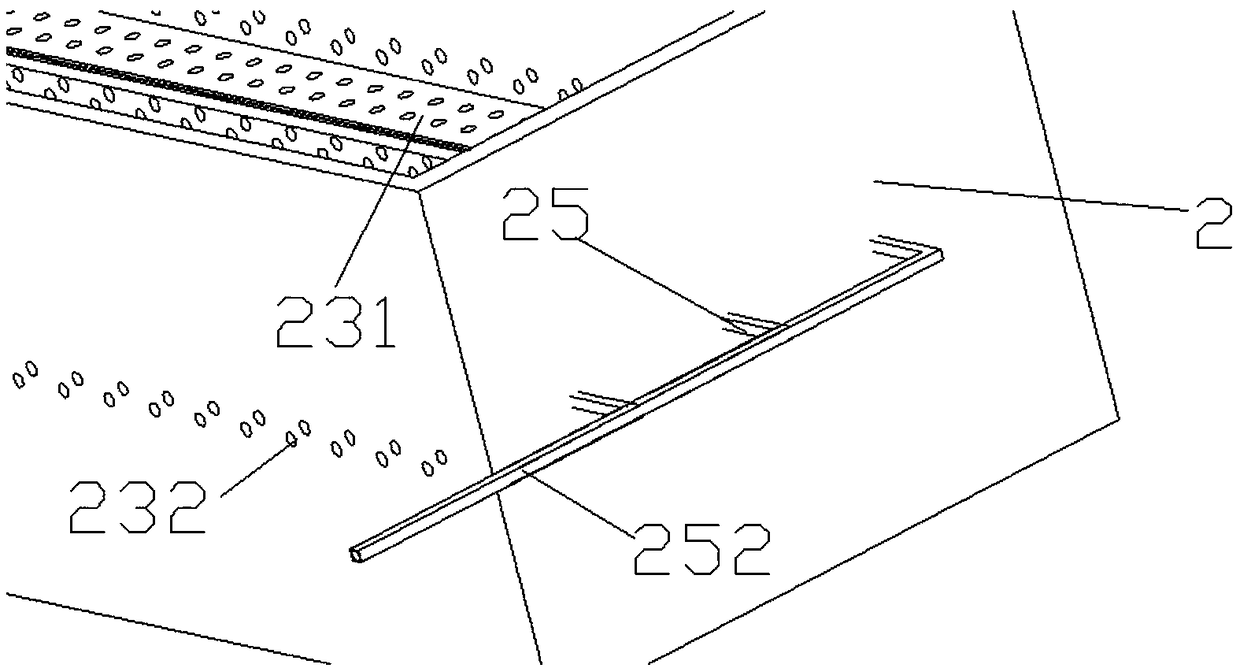

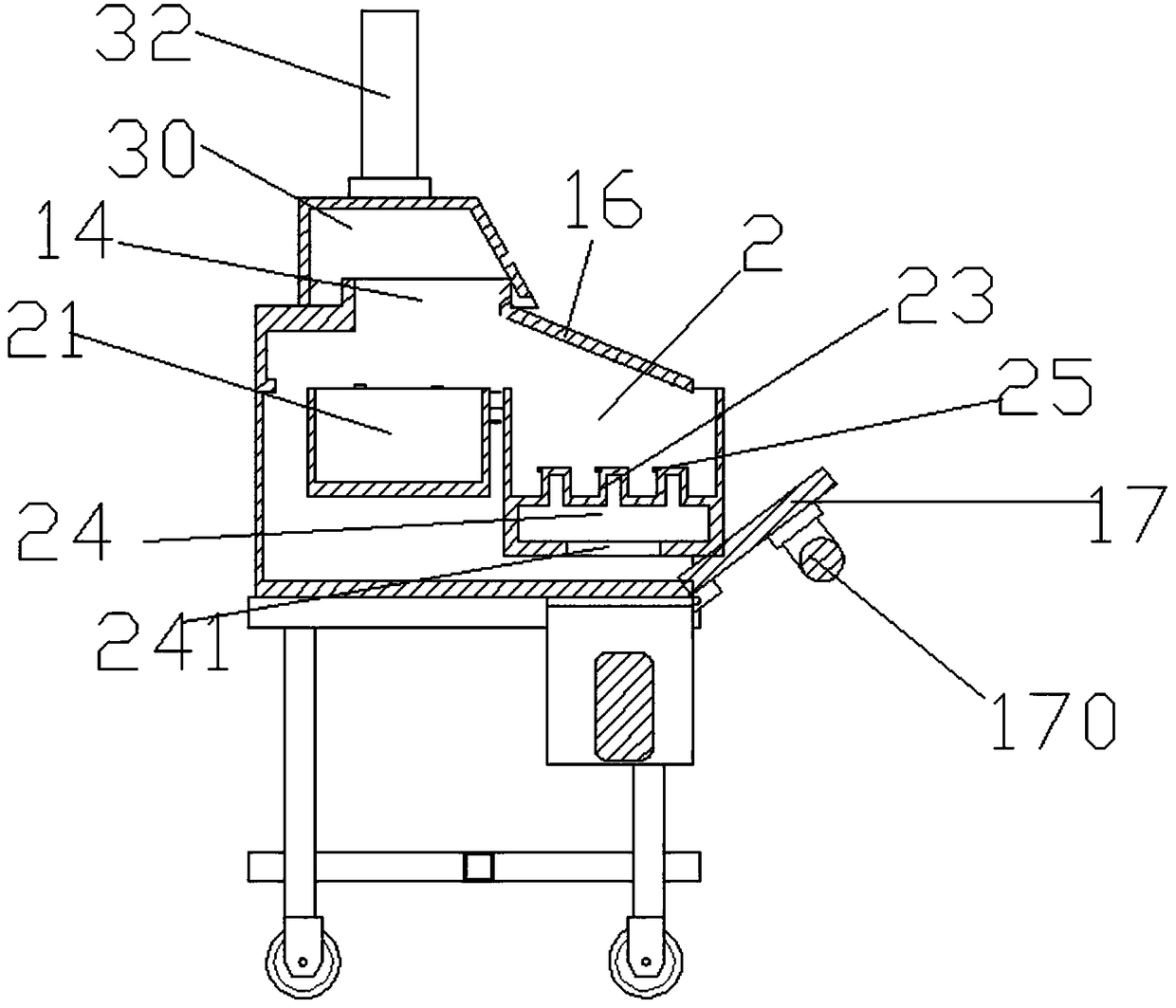

[0040] The smokeless grill with high efficiency, environmental protection and energy saving includes a box body 1, a box body cover 17, a retractable chimney 32, a charcoal tank 2, an oil receiving tank 21, an air duct 24, a gas pipe 25 and a blower.

[0041] The inner side of the oven box 1 is pasted with an insulating layer, the surface of the insulating layer is covered with refractory materials, and the inner refractory material of the oven is refractory bricks. Both sides of the upper part of the box body 1 are provided with elongated openings 11, and one end of the elongated opening 11 is provided with an arc section 110, and the inner side of the box body below the elongated opening 11 is provided with a slide rail 12, Two elongated concave brackets 13 are arranged on the inside of the slide rail 12 front and back. The groove bottom of the elongated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com