Method for repairing partial layering of titanium-steel explosion cladding plate

A technology of explosive clad plate and repair method, which is applied in the repair field of partial delamination of titanium-steel explosive clad plate, which can solve the problems that the steel cannot be directly welded and the plate is scrapped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

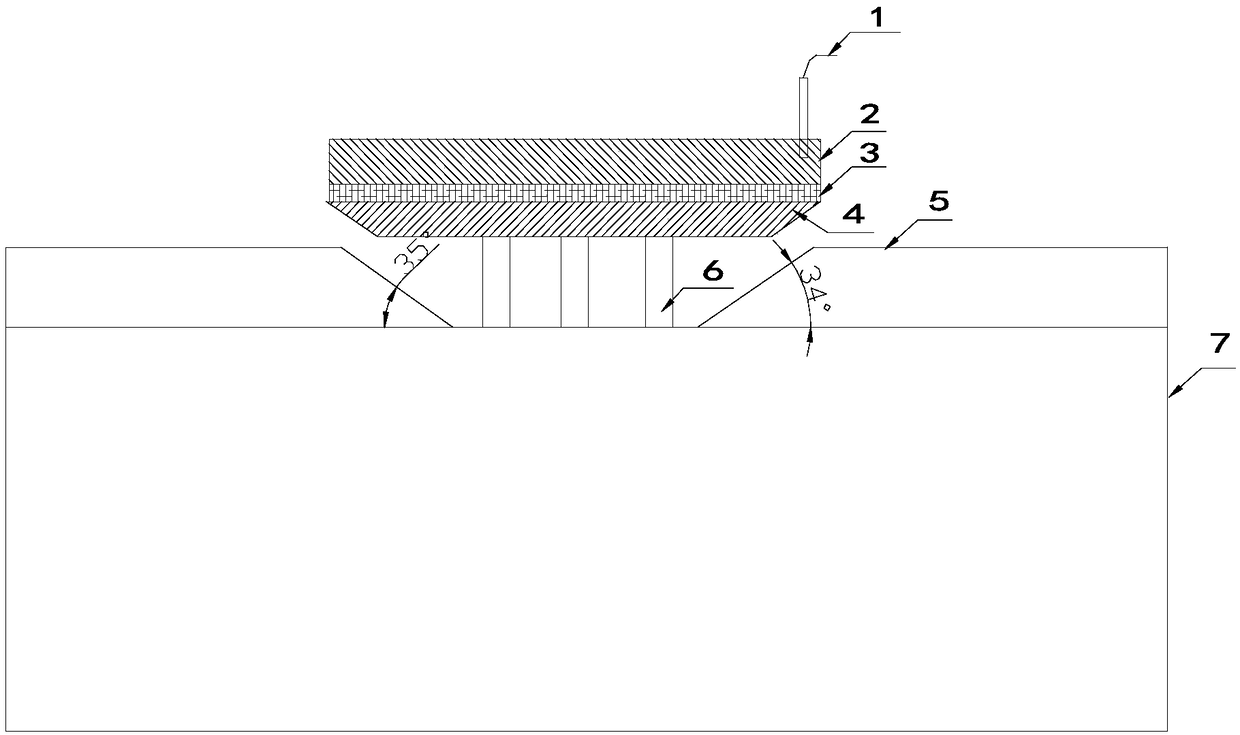

[0024] According to the analysis, the delamination area of the titanium-steel explosive clad plate mainly appears at the initiation point or the poorly bonded area. In order to repair the above-mentioned titanium-steel explosive clad plate, the following steps were adopted:

[0025] 1. Ultrasonic testing is performed on the layered area to confirm its size, and then the titanium layer in the layered area is removed. When removing, it is necessary to cut off the connection with the titanium layer in the layered area from the area with a good bonding layer. This process is In order to prevent the removal of the titanium layer in the delamination area from causing the titanium layer in other areas to lift off.

[0026] 2. Then lift the titanium layer in the delamination area to separate it from the steel plate.

[0027] 3. Grind the layered area with a grinder to remove the texture of the joint surface, and grind the surrounding original titanium layer 5 of the composite plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com