Forming method of aluminum-copper composite material shaped charge cover

A composite material and drug-type cover technology, applied in the field of composite material manufacturing, can solve the problems of non-dense material, low strength, high brittleness, etc., and achieve the effect of improving interface bonding force, ensuring tissue properties, and high ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for forming an aluminum-copper composite drug-type cover, using the following steps:

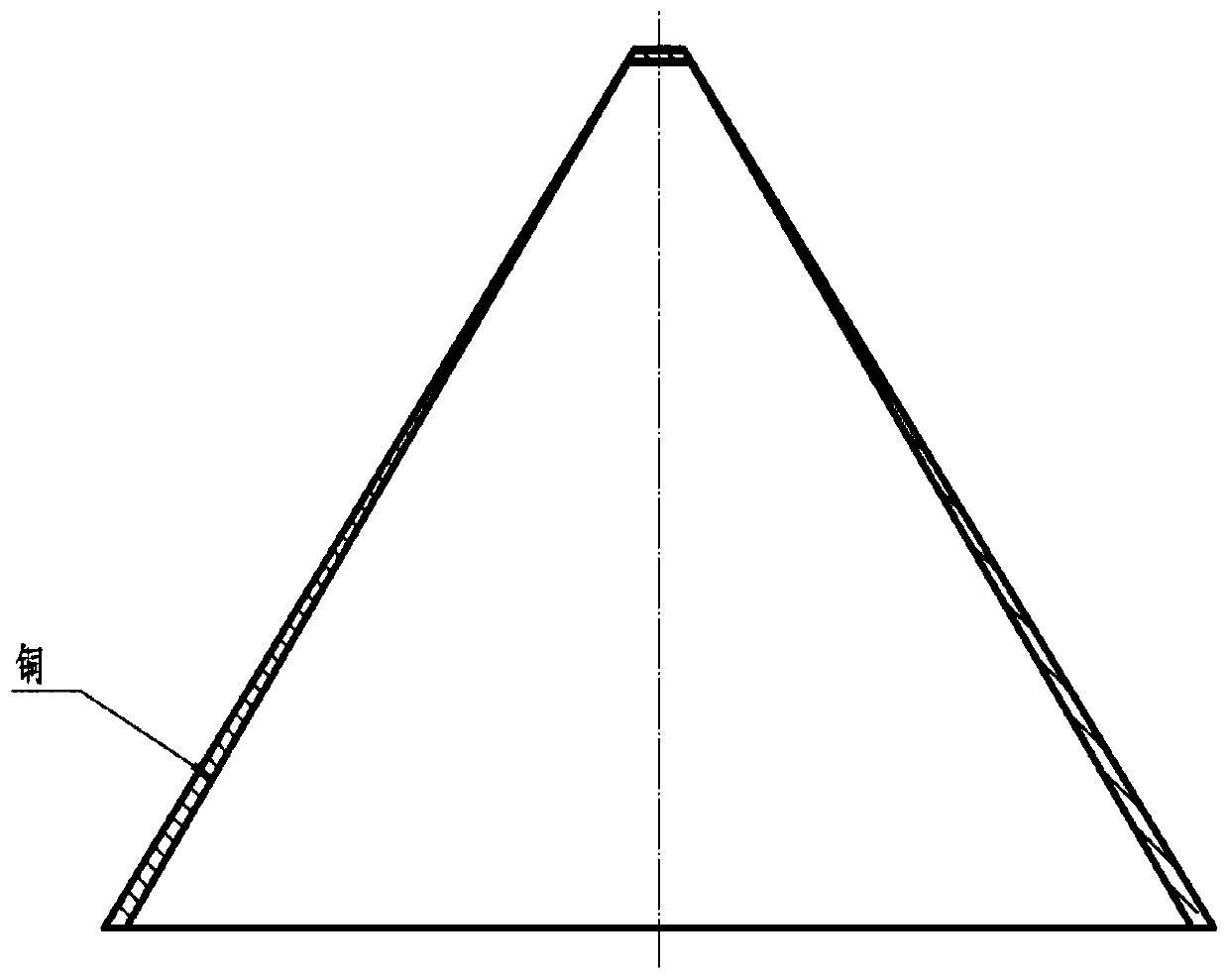

[0035] (1) The cold-extruded pure copper drug-shape blank (TU1) is subjected to recrystallization heat treatment at 320°C for 60 minutes, and the measured average grain size is (10-15) μm; on, follow figure 1 The shape and structure are processed by cutting. Taking 5 products as samples, the angle deviation of the outer taper is -1.2'~0.7', and the surface roughness is (0.42~0.68)μm.

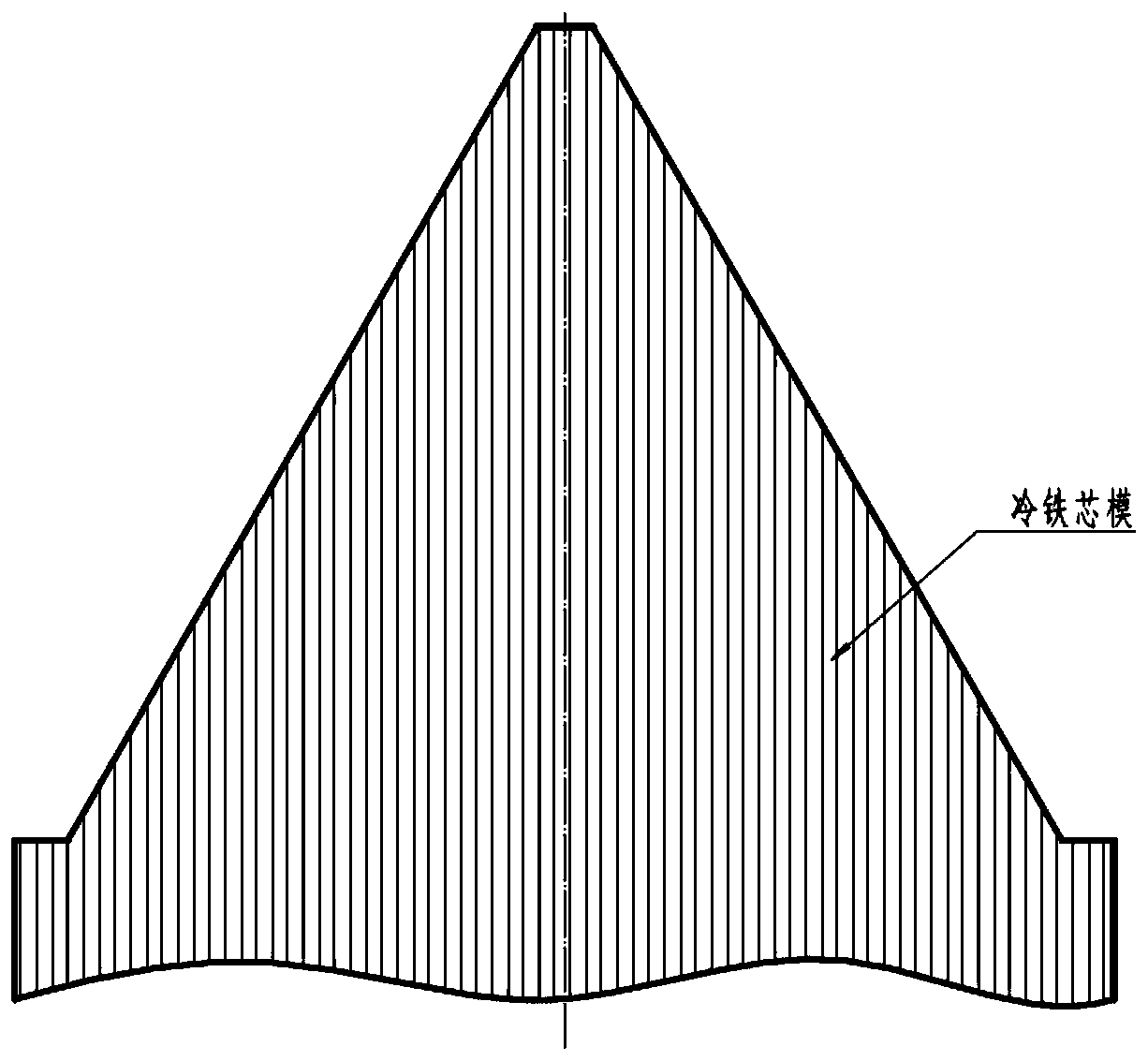

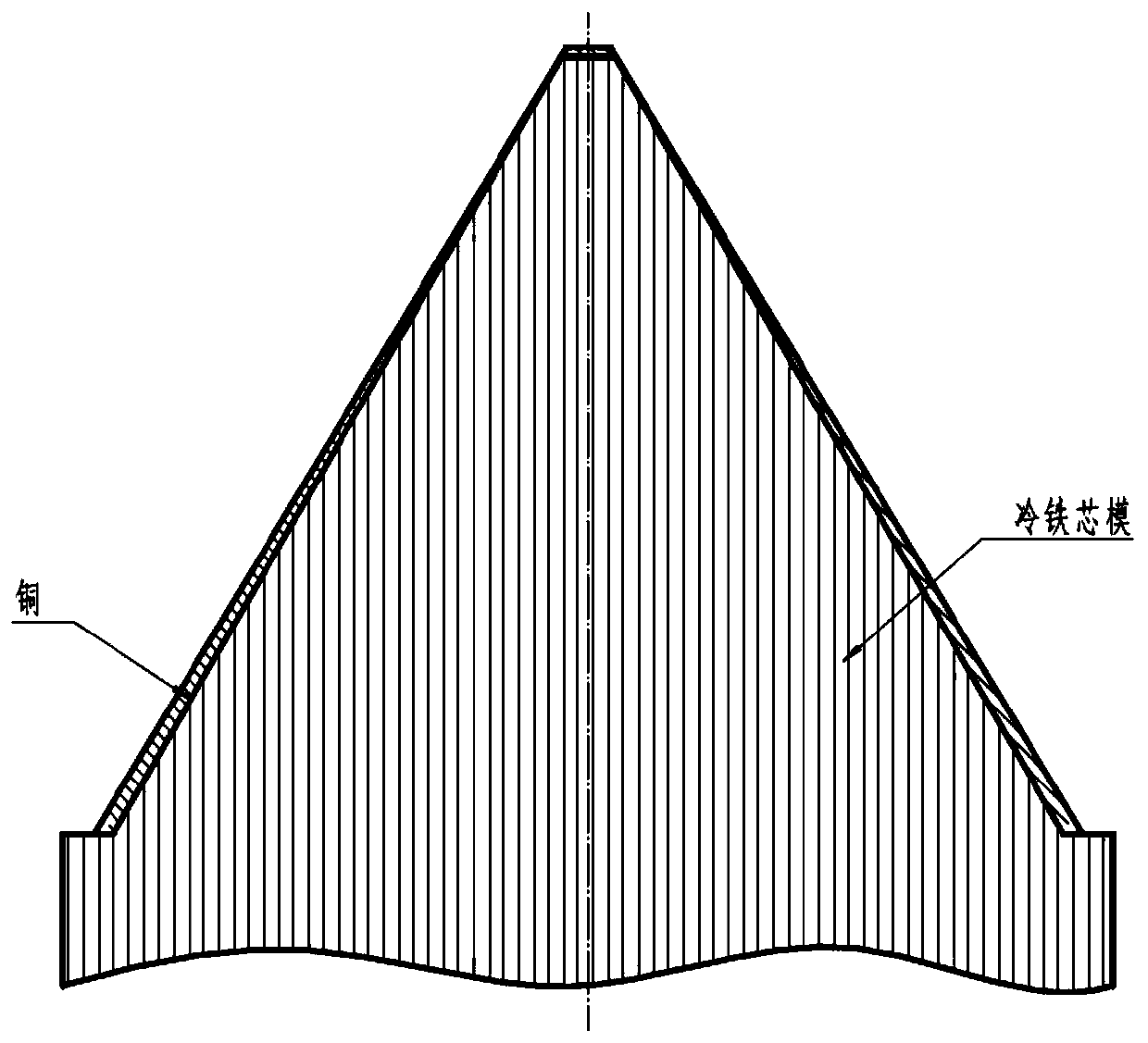

[0036] (2) According to the inner size of the pure aluminum-copper composite drug-type cover, the copper rod is processed into a matching cold iron core mold ( figure 2 ), the surface roughness is 0.4μm, and the angle deviation is 0.2′, and it is assembled with the copper cone shell obtained in (1), and the bonding rate of the cone surface is 85% to 90% ( image 3 ).

[0037] (3) After melting the paraffin, pour out the shape and structure of the pure aluminum outer layer of the aluminum-co...

Embodiment 2

[0045] A method for forming an aluminum-copper composite drug-type cover, using the following steps:

[0046] (1) The cold-extruded pure copper drug-mold blank (T2) is subjected to recrystallization heat treatment at 350°C for 60 minutes, and the measured average grain size is (5-8) μm; in the CNC processing equipment on, follow figure 1 The shape and structure are cut and processed, taking 5 products as samples, the angle deviation of the outer taper is -0.9'~1', and the surface roughness is (0.34~0.52)μm.

[0047] (2) According to the inner size of the pure aluminum-copper composite drug-type cover, the copper rod is processed into a matching chilled iron mandrel with a surface roughness of 0.4 μm and an angle deviation of 0.2′, and (1) is obtained The copper cone shell is assembled, and the bonding rate of the two cone surfaces is 80% to 85%.

[0048] (3) After melting the paraffin, pour out the shape and structure of the pure aluminum outer layer of the aluminum-copper c...

Embodiment 3

[0056] A method for forming an aluminum-copper composite drug-type cover, using the following steps:

[0057] (1) The cold-extruded pure copper drug-mold blank (TU1) is subjected to recrystallization heat treatment at 300°C for 75 minutes, and the measured average grain size is (5-8) μm; on, follow figure 1 The shape and structure are processed by cutting. Taking 5 products as samples, the angle deviation of the outer taper is -1.2'~0.3', and the surface roughness is (0.52~0.73)μm.

[0058] (2) According to the inner size of the pure aluminum-copper composite drug-type cover, the copper rod is processed into a matching chilled iron mandrel with a surface roughness of 0.4 μm and an angle deviation of 0.2′, and (1) is obtained The copper cone shell is assembled, and the bonding rate of the two cone surfaces is 88% to 92%.

[0059] (3) After melting the paraffin, pour out the shape and structure of the pure aluminum outer layer of the aluminum-copper composite drug-type cover, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com