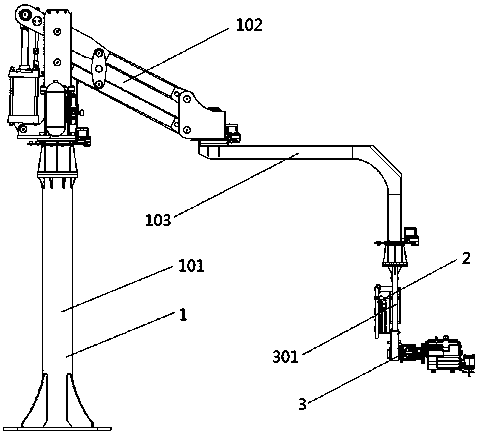

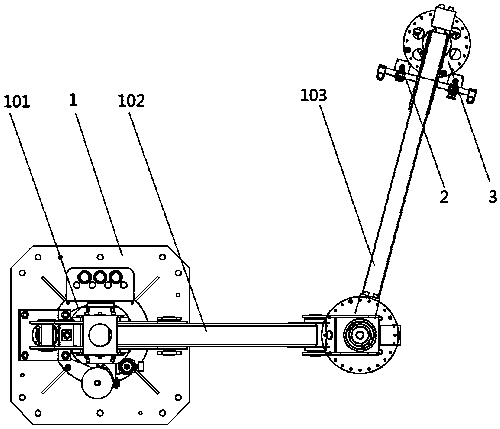

Pure pneumatic power-assisted mechanical arm device

A robotic arm, pure gas technology, applied in the directions of manipulators, claw arms, conveyor objects, etc., can solve the problems of high labor intensity, low safety factor, low turnover efficiency of workers, etc., to achieve good promotion and application prospects, reduce labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

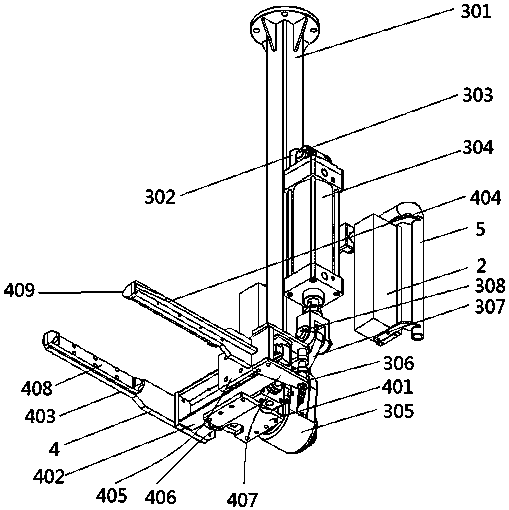

[0023] Embodiment 2, a purely pneumatic power-assisted mechanical arm device, the pneumatic clamp 4 includes a clamp connecting plate 401 fixedly arranged on the turning shaft 311, a slide rail 402 is fixedly arranged on the clamp connecting plate 401, and one end of the slide rail 402 is fixed A first claw 403 is provided, and a second claw 404 is movably provided at the other end. The second claw 404 is fixedly arranged on a sliding frame 405 slidingly matched with the slide rail 402 . The frame 405 is a clamping cylinder 406 that slides in the slide rail 313 , and the control unit 2 also includes a clamping control valve 202 that controls the action of the clamping cylinder 406 . The clamping cylinder 406 drives the second jaw 404 to move while the first jaw 403 is fixed, not only can clamping and unfolding of the fixture be achieved, but also only one jaw has a simple and compact structure and is convenient for production.

[0024] Other structures of this embodiment are t...

Embodiment 3

[0025] Embodiment 3, a purely pneumatic power-assisted mechanical arm device, the turning link 307 is arc-shaped, the transmission gear 306 is a sector gear, and the arc-shaped turning link 307 and the sector gear are integrated. The turning connecting rod 307 is arranged in an arc shape, which can evenly push the transmission gear 306 to rotate with the action of the turning cylinder 304, and then make the turning shaft 311 evenly rotate, and can accurately stop at different positions to facilitate processing of workpieces.

[0026] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 4

[0027] Embodiment 4, a purely pneumatic power-assisted mechanical arm device, the limit structure includes two bolt seats 701 arranged on the outside of the turning shaft seat 305, and the two bolt seats 701 are arranged in the same horizontal plane and are left and right symmetrical. Limiting bolts 702 are arranged in the bolt seats 701, the shaft end of the turning shaft 311 is fixedly provided with a connecting flange 703, the connecting flange 703 is fixedly connected with the fixture connecting plate 401, and one side of the connecting flange 703 is provided with a limiting bolt. 702 blocks the limit block 704 that cooperates. The setting of the connecting flange 703 can fully ensure the reliability of the connection between the fixture connecting plate 401 and the turning shaft 311; the limit structure is designed as a form of cooperation between the limit bolt 702 and the limit block 704, which can not only realize the rotation of the turning shaft 311 Limit, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com