Making method of baijiu

A technology of liquor and distiller's yeast, which is applied in the field of wine brewing, can solve the problems of shortening fermentation time, long fermentation time, and low brewing efficiency, and achieve the effects of shortening fermentation time, promoting anaerobic respiration, and accelerating reproduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A brewing method of white wine, comprising the following steps:

[0032] 1) Raw material crushing, 50 parts by weight of the grain is crushed to 20-22 mesh to obtain the raw material, the raw material is a mixture of sorghum, corn and barley.

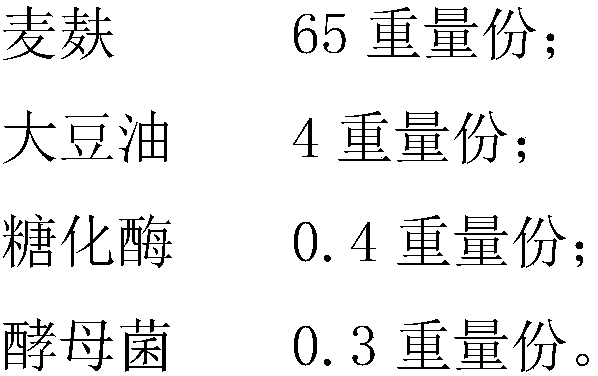

[0033] 1) Measure distiller's yeast, measure the distiller's yeast of 0.5 weight part, described distiller's yeast comprises bacterial classification, wheat bran and soybean oil, and described bacterial classification comprises the specific proportioning of each component of described distiller's yeast described in glucoamylase and yeast as follows:

[0034]

[0035] 2) batching, the raw material and the koji are placed in a closed container and mixed, then 105 parts by weight of water and 4 parts by weight of soybean powder are added, and the starch concentration is adjusted to 14% by adding auxiliary materials in the closed container, and the pH The value is 4.5. The auxiliary materials are rice husk, rice bran and corn cob...

Embodiment 2

[0047] A brewing method of white wine, comprising the following steps:

[0048] 1) Raw material crushing, 55 parts by weight of the grain is crushed to 22-23 mesh to obtain the raw material, the raw material is a mixture of barley, sweet potato, cassava;

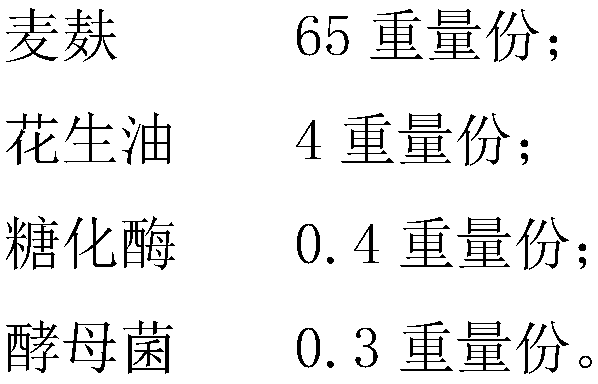

[0049] 1) measure distiller's yeast, measure the distiller's yeast of 0.7 weight part, described distiller's yeast comprises bacterial classification, wheat bran and soybean oil, and described bacterial classification comprises the specific proportioning of each component of described distiller's yeast described in glucoamylase and yeast as follows:

[0050]

[0051] 2) batching, the raw material and the koji are placed in a closed container and mixed, then 110 parts by weight of water and 6 parts by weight of soybean powder are added, and the starch concentration is adjusted to 15% by adding auxiliary materials in the closed container, and the pH The value is 4.7. The auxiliary material is a mixture of rice husk, rice b...

Embodiment 3

[0063] A brewing method of white wine, comprising the following steps:

[0064] 1) The raw material is pulverized, and the grain of 58 parts by weight is pulverized to 24 orders to obtain the raw material, and the raw material is a mixture of sugarcane and sugar beet;

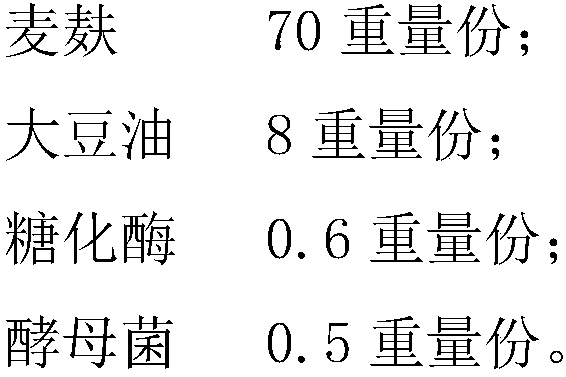

[0065] 1) Measure distiller's yeast, measure the distiller's yeast of 0.8 weight part, described distiller's yeast comprises bacterial classification, wheat bran and soybean oil, and described bacterial classification comprises the specific proportioning of each component of described distiller's yeast described in glucoamylase and yeast as follows:

[0066]

[0067]

[0068] 2) Ingredients, the raw material and the koji are placed in a closed container and mixed, then 120 parts by weight of water and 7 parts by weight of soybean powder are added, and the starch concentration is adjusted to 15% by adding auxiliary materials in the closed container, and the pH The value is 4.9. The auxiliary material is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com