Low-temperature fluorine-resistant leaching bacteria and its bioleaching process for fluorine-containing uranium ore

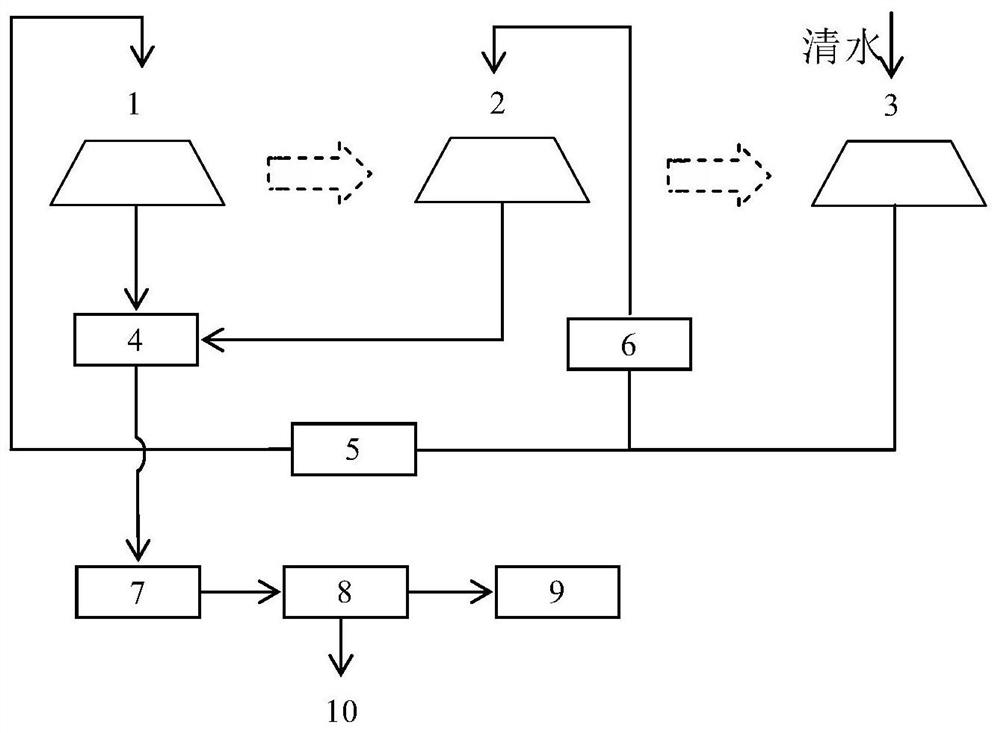

A technology of leaching bacteria and low temperature, which is applied in the bioleaching process of high-efficiency extraction of uranium, and in the field of bacterial strains grown in a low-temperature and high-fluorine environment, which can solve the problems of low uranium concentration, difficulty in passing standards, and reduced uranium leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Domestication and cultivation of low-temperature fluorine-resistant leaching bacteria

[0045] 1) Collection:

[0046] The ore-leaching bacteria solution was collected from the pit water of a fluorine-containing mine in Jiangxi, and the ore-leaching bacteria solution was inoculated in 9K medium, the inoculation solution accounted for 20%, and the pH value was adjusted to 2.0. 15°C, shaker rotation speed 160rpm. Microscopic counting of bacterial growth to the logarithmic phase, Fe in the culture solution 2+ When the concentration is lower than 0.2g / L, concentrate the leaching bacteria solution, and then inoculate it into a new 9K medium for cultivation. Do this until the growth period of the ore-leaching bacteria is shortened to within 2 days and tends to be stable.

[0047] The cultured ore-leaching bacteria solution was centrifuged to collect the bacteria, and then the bacteria were acclimated to fluorine resistance.

[0048] 2) Acclimatization under l...

Embodiment 2

[0055] Embodiment 2: Bioleaching of certain fluorine-containing uranium ore

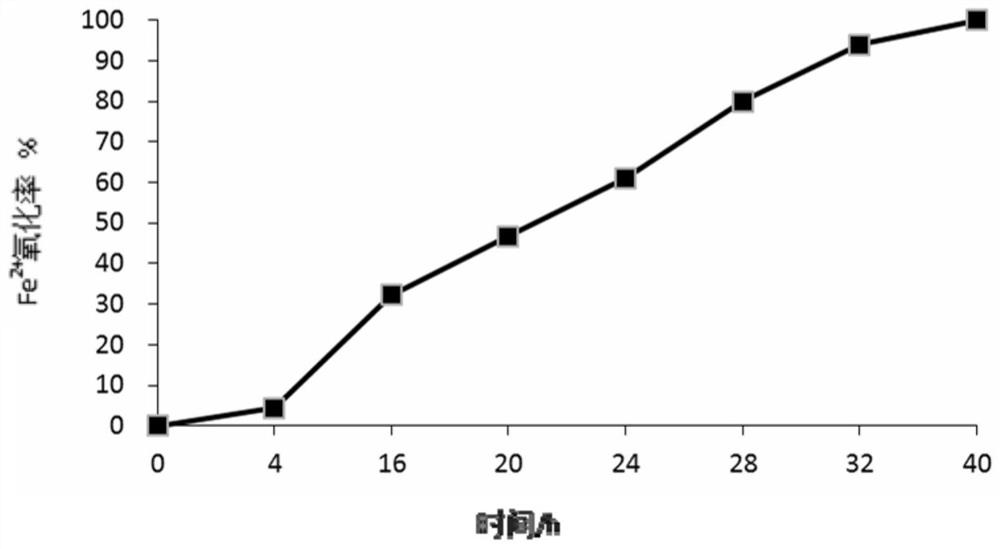

[0056] The semi-quantitative fluorescence (XRF) analysis results of fluorine-containing uranium ores in a certain place in Jiangxi are shown in Table 1. Chemical analysis of reduced uranium (U 4+ ) is 0.251%, oxidized uranium (U 6+ ) is 0.062%, so the uranium ore is difficult to achieve a higher leaching rate by general acid leaching process. The chemical analysis shows that the fluorine content in the ore is 0.726%. Although the fluorine content in the raw ore is not very high, after the ore is leached, the fluorine will gradually accumulate with the recycling of the tailing liquid, and the fluorine concentration will reach several grams. The low-temperature fluorine-resistant leaching bacteria Acidithiobacillus ferrooxidans Retech KF-Ⅳ (CGMCC No.13018) domesticated in Example 1 was used as the oxidized Fe 2+ strains, to obtain the strains and Fe 3+ of the immersion solution.

[0057] Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com