Pelletized seeds suitable for rice direct sowing and pelletizing method of pelletized seeds

A rice seed pelletization technology, which is applied in the direction of seed coating/seed dressing, etc., can solve the problems of poor hardness of pelletized seeds, unfavorable germination and emergence, and small drug load, and achieve reasonable compounding and general Good water and aeration effect, and the effect of reducing planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

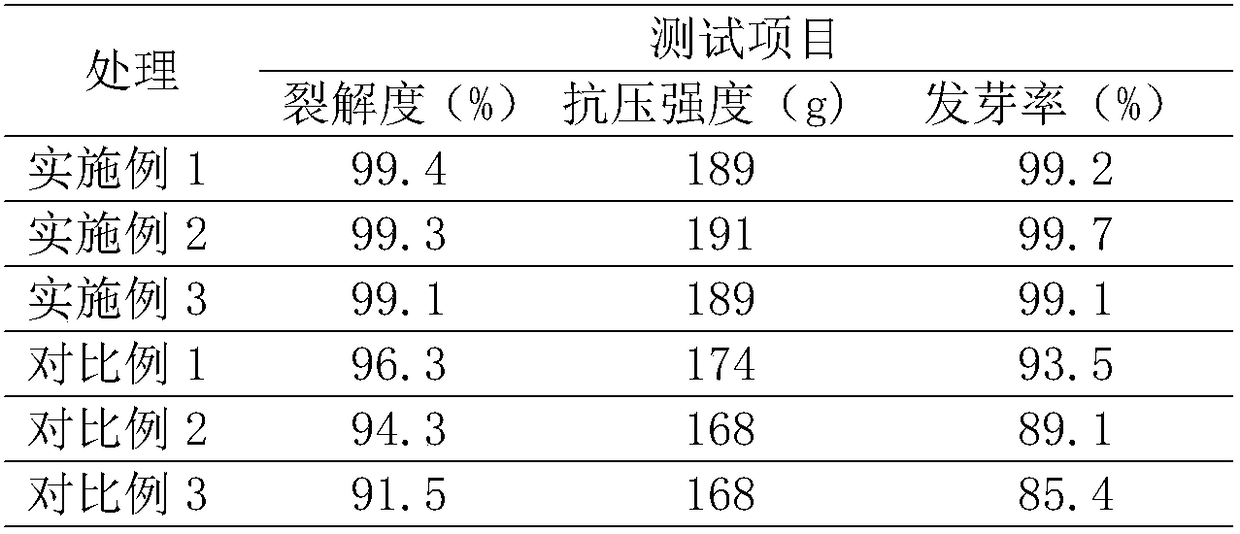

Examples

Embodiment 1

[0031] A kind of preparation of paddy rice pelletized seed, comprises the steps:

[0032] A. Select rice seeds: purify the rice seeds to be pelletized to remove sand and sundries in the seeds;

[0033] B. Put the seeds into the coating container, spray the seeds with a liquid composition containing a binder (calcium peroxide: carboxymethyl cellulose 1:1) while the container is rotating, and then put in a coating containing silicon dioxide and bentonite a coating composition to bind the seed;

[0034] C. Pour the granulated seeds obtained in step B into the coating container, continue to repeat step B, carry out the above operation every 40 seconds, repeat three times, and obtain pelletized seeds;

[0035] D. Suspending and drying the pelleted seeds obtained in step C to obtain uniform pelleted seeds.

Embodiment 2

[0037] A kind of preparation of paddy rice pelletized seed, comprises the steps:

[0038] A. Select rice seeds: purify the rice seeds to be pelletized to remove sand and sundries in the seeds;

[0039] B. Put the seeds into the coating container, spray the seeds with a liquid composition containing a binder (calcium peroxide: polyvinyl alcohol weight ratio 1:3) while the container is rotating, and then put in a coating containing silicon dioxide and bentonite a coating composition to bind the seed;

[0040] C. Pour the granulated seeds obtained in step B into the coating container, continue to repeat step B, carry out the above operation every 60 seconds, repeat three times, and obtain pelletized seeds;

[0041] D. Suspending and drying the pelleted seeds obtained in step C to obtain uniform pelleted seeds.

Embodiment 3

[0043] A kind of preparation of paddy rice pelletized seed, comprises the steps:

[0044] A. Select rice seeds: purify the rice seeds to be pelletized to remove sand and sundries in the seeds;

[0045] B. Put the seeds into the coating container, spray the seeds with a liquid composition containing a binder (calcium peroxide: cellulose weight ratio 1:5) while the container is rotating, and then drop into the coating containing silicon dioxide and bentonite. a coating composition to bind the seed;

[0046] C. Pour the granulated seeds obtained in step B into the coating container, continue to repeat step B, carry out the above operation every 50 seconds, repeat three times, and obtain pelletized seeds;

[0047] D. Suspending and drying the pelleted seeds obtained in step C to obtain uniform pelleted seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com