Catalyst based on volatile organic pollutant purification and preparation method

A volatile organic and pollutant technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of removal of unfavorable organic pollutants, high ignition temperature, catalytic oxidation of unfavorable organic pollutants, etc. , to achieve the effect of improving competitiveness, low CO light-off temperature, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

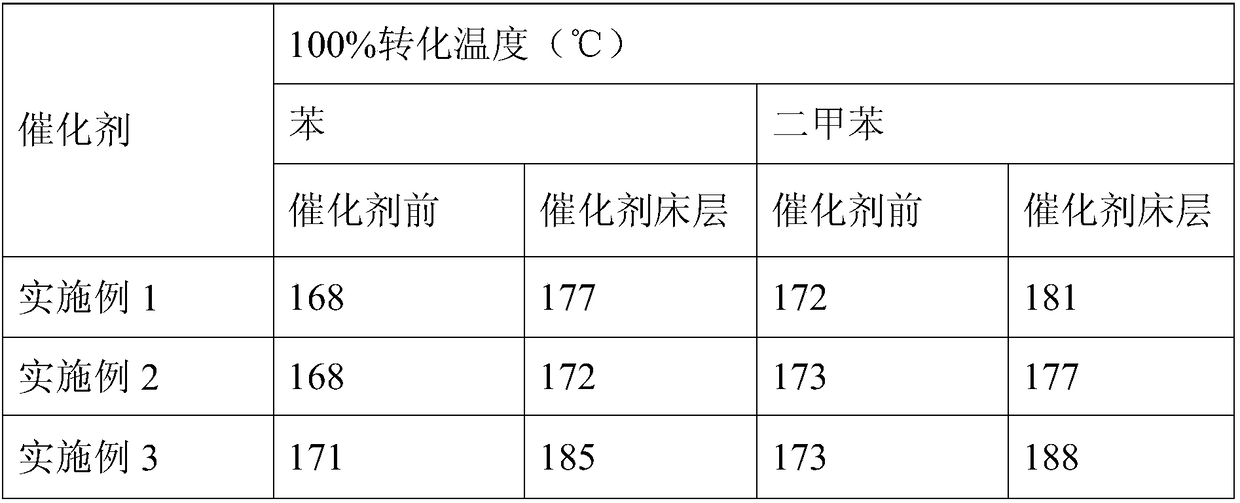

Embodiment 1

[0026] Embodiment one: a kind of preparation method of organic pollutant catalytic oxidation catalyst, comprises the steps:

[0027] Precious metal loading steps:

[0028] (1) Weighing of materials: Weigh silicon Al according to the weight ratio of 0.76:0.2:0.04 2 o 3 , ZSM-5 molecular sieve, ZrO 2 (Zr(NO 3 ) 4 ·5H 2 O cured product), the total weight of the powder is 1000g, which is converted into Zr(NO 3 ) 4 ·5H 2 The weight of O is 121.2g;

[0029] (2) Weighing of precious metals: the amount of precious metals is 90g / ft 3 , the mass ratio of precious metal Pt and Pd is 3:2, and the coating amount is 80g / l;

[0030] (3) Loading of precious metal Pt: Zr(NO 3 ) 4 ·5H 2 O dissolves in the noble metal Pt(NO 3 ) 2 Add ethanol to the solution and dilute to 171g (90% of the water absorption of ZSM-5 molecular sieve), impregnate it on the ZSM-5 molecular sieve for incipient wetness, and age for 12h;

[0031] (4) Treatment of precious metal Pt materials: drying and ro...

Embodiment 2

[0040] Embodiment two: a kind of preparation method of catalytic oxidation catalyst of organic pollutants, comprises the following steps:

[0041] Precious metal loading steps:

[0042] (1) Weighing of materials: Weigh silicon Al according to the weight ratio of 0.67:0.3:0.03 2 o 3 , ZSM-5 molecular sieve, ZrO 2 (Zr(NO 3 ) 4 ·5H 2 O cured product), the total weight of the powder is 1000g, which is converted into Zr(NO 3 ) 4 ·5H 2 The weight of O is 90.0g;

[0043] (2) Weighing of precious metals: the amount of precious metals is 90g / ft 3 , the mass ratio of precious metal Pt and Pd is 3:2, and the coating amount is 80g / l;

[0044] (3) Loading of precious metal Pt: Zr(NO 3 ) 4 ·5H 2 O dissolves in the noble metal Pt(NO 3 ) 2 Add ethanol to the solution and dilute to 256.5g (90% of the water absorption of ZSM-5 molecular sieve) incipient wetness impregnation on ZSM-5 molecular sieve, aging for 12h;

[0045] (4) Treatment of precious metal Pt materials: drying and...

Embodiment 3

[0054] Embodiment three: a kind of preparation method of catalytic oxidation catalyst of organic pollutants, comprises the following steps:

[0055] Precious metal loading steps:

[0056] (1) Weighing of materials: Weigh silicon Al according to the weight ratio of 0.57:0.4:0.03 2 o 3 , ZSM-5 molecular sieve, ZrO 2 (Zr(NO 3 ) 4 ·5H 2 O cured product), the total weight of the powder is 1000g, which is converted into Zr(NO 3 ) 4 ·5H 2 The weight of O is 90.9g;

[0057] (2) Weighing of precious metals: the amount of precious metals is 60g / ft 3 , the mass ratio of precious metal Pt and Pd is 2:1, and the coating amount is 120g / l;

[0058] (3) Loading of precious metal Pt: Zr(NO 3 ) 4 ·5H 2 O dissolves in the noble metal Pt(NO 3 ) 2 Add ethanol to the solution and dilute to 342g (90% of the water absorption of ZSM-5 molecular sieve), impregnate it on the ZSM-5 molecular sieve for incipient wetness, and age for 12h;

[0059] (4) Treatment of precious metal Pt material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com