Platinum-based oxidation catalyst for diesel vehicles and preparation method thereof

A technology for catalysts and diesel vehicles, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of aging catalyst performance degradation, high content of precious metals in coatings, poor low temperature performance, etc., to improve competition simple preparation method, good low temperature light-off activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

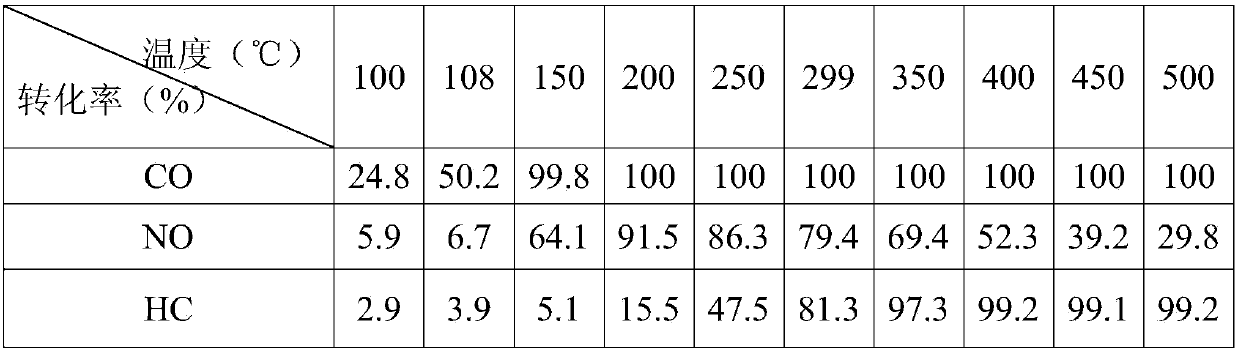

Embodiment 1

[0030] Embodiment one: the preparation method of platinum-based oxidation catalyst for diesel vehicles comprises the following steps:

[0031] Contact layer slurry preparation and coating

[0032] (1) Preparation of contact layer slurry: Al 2 o 3 1. Zirconium acetate is added to deionized water at a weight ratio of 0.96:0.04, fully stirred evenly, and nitric acid is added to adjust the pH of the slurry to 4.45;

[0033] (2) Contact layer slurry ball milling: the slurry is ground by a planetary ball mill, the speed of the planetary ball mill is 250 rpm, the running time is 6h, and the particle size of the slurry is 15.3um to D90;

[0034] (3) Determination of the solid content in the contact layer slurry: Take 10 g of the slurry in a dry pot, place the dry pot in a muffle furnace at 550 ° C for 20 minutes, cool to room temperature, weigh the powder mass as 2.81 g, and use the The mass is divided by 10g, and the solid content of the slurry is 28.1%;

[0035] (4) Contact laye...

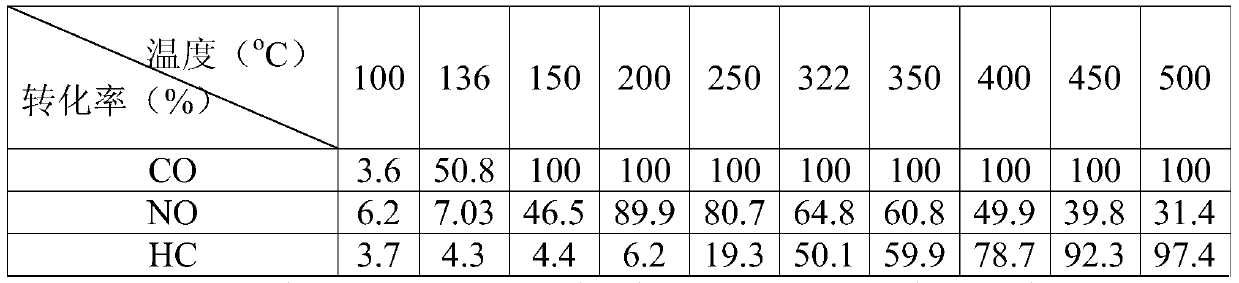

Embodiment 2

[0048] Embodiment two: the preparation method of diesel vehicle platinum-based oxidation catalyst, comprises the following steps:

[0049] Contact layer slurry preparation and coating

[0050] (1) Preparation of contact layer slurry: Al 2 o 3 1. Add zirconium acetate to deionized water, the weight ratio is 0.93:0.07, stir well, add nitric acid to adjust the pH of the slurry to 4.43;

[0051] (2) Contact layer slurry ball milling: the slurry is ground by a planetary ball mill, the speed of the planetary ball mill is 320 rpm, the running time is 4h, and the particle size of the slurry is 12.3um to D90;

[0052] (3) Determination of the solid content in the contact layer slurry: take 10 g of the slurry in a dry pot, place the dry pot in a muffle furnace at 580 ° C for 20 minutes, cool to room temperature, weigh the powder mass as 2.78 g, and use the The mass is divided by 10g, and the solid content of the slurry is 27.8%;

[0053] (4) Contact layer coating: Coating with a qua...

Embodiment 3

[0066] Embodiment three: the preparation method of diesel vehicle platinum-based oxidation catalyst, comprises the steps:

[0067] Contact layer slurry preparation and coating

[0068] (1) Preparation of contact layer slurry: Proportionally mix Al 2 o 3 1. Add zirconium acetate to deionized water, the weight ratio is 0.9:0.1, stir well, add nitric acid to adjust the pH of the slurry to 4.38;

[0069] (2) Contact layer slurry ball milling: the slurry is ground by a planetary ball mill, the rotation speed of the planetary ball mill is 380 rpm, the running time is 3h, and the particle size of the slurry reaches D90 of 11.4um;

[0070] (3) Determination of solid content in contact layer slurry: Take 10g of slurry in a dry pot, place the dry pot in a muffle furnace at 600°C for 10 minutes, cool to room temperature, weigh the powder mass as 2.69, use the mass Divided by 10g, the solid content of the slurry is 26.9%;

[0071] (4) Contact layer coating: Coating with a quantitative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com