A fuel tank production process and inflation device

A production process and oil tank technology, applied in the direction of providing/removing protective gas devices, manufacturing tools, metal processing equipment, etc., can solve problems such as fuel tank failures and splash failures, and meet the requirements of ensuring cleanliness, reducing splashes, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

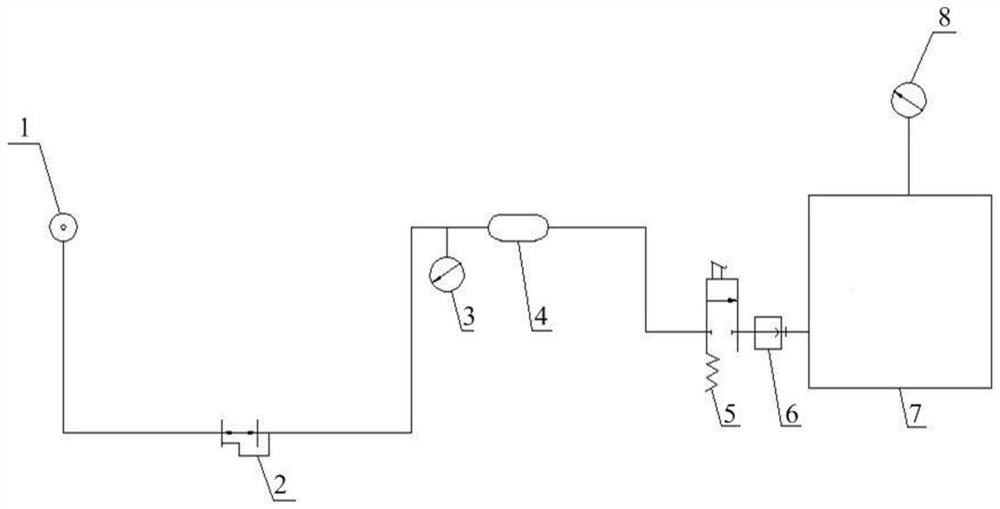

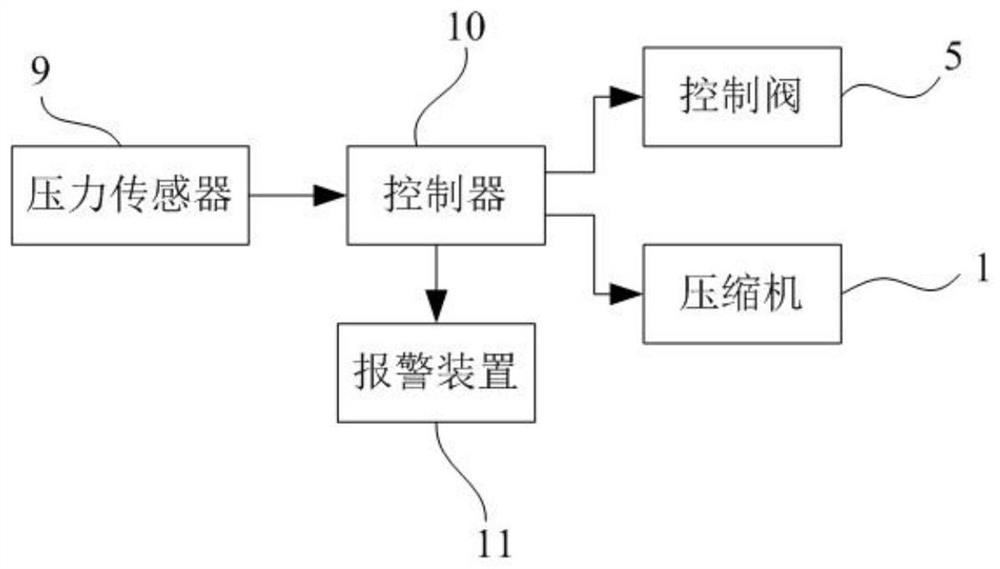

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0031] This embodiment discloses a fuel tank production process, including the following steps:

[0032] Assemble boxes for processed plates before welding;

[0033] The hole on the fuel tank 7 to be welded is sealed;

[0034] Since the plate of the fuel tank 7 to be welded has holes connecting the fuel tank with other parts, all the holes are sealed before welding. The specific sealing method is to cover the holes with a cover plate and lock them with bolts. In order to enhance the sealing performance , There is a sealing ring between the cover plate and the edge of the hole to ensure that there is no air leakage at the opening. It can not only reduce air leakage for the subsequent inflation process, but also prevent spatter from entering the interior of the fuel tank through the opening to cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com