Returned mine sintering process and system

A technology of returning ore and process, applied in the field of ore sintering process and system, can solve the problems of the limit of the maximum usage of quicklime, the decrease of the added value of the ball-forming effect, and the increase of equipment specifications, etc. The effect of improving breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a sintering process for returning ore, including: sintering material preparation, intercalation material acquisition and mixing process;

[0037] The preparation of the sintered material includes a sintered material mixing process and a sintered material granulation process; wherein,

[0038] The sinter mixing process: adding powdered fuel and flux to the iron ore powder, mixing the iron ore powder, fuel and flux to form a mixture;

[0039] The sintered material granulation process: adding water to the mixed material, using steam to preheat the mixed material, and preparing the mixed material into granular sintered material;

[0040] The acquisition of the embedded material includes a pellet screening process and an embedded material storage process; wherein,

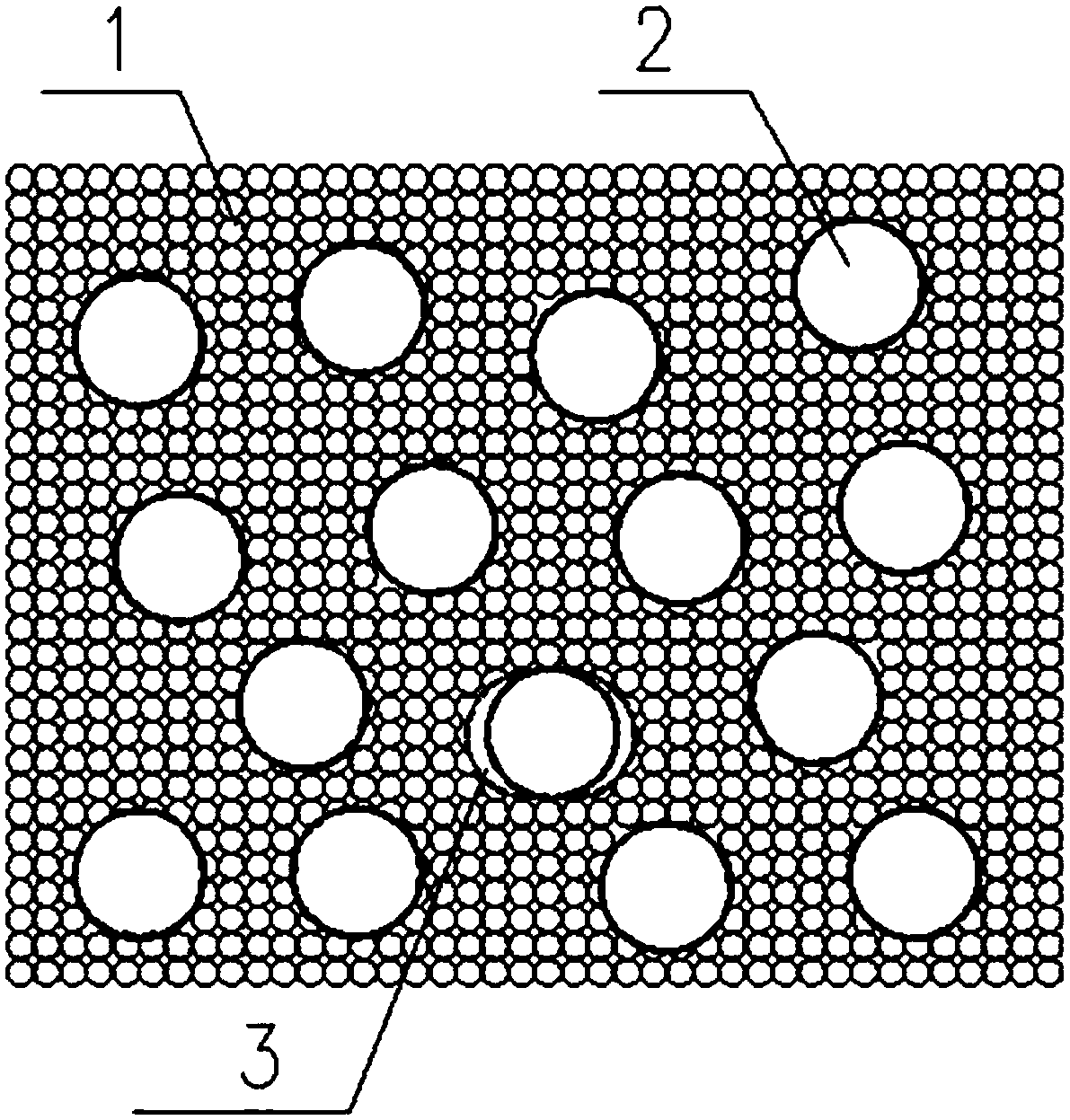

[0041] The pellet material screening process: firstly adjust the sieve hole, adjust the sieve hole diameter to 5mm, sieve the iron and steel metallurgical pellets or the pellets under th...

Embodiment 2

[0048] On the basis of the above-mentioned embodiment, the average rate of inputting the returning ore material to the described anti-mine bin in the described embedded material storage process is the input rate, and the output rate of the returning ore material from the described returning ore bin during the mixing process is The rate is the output rate, the input rate is equal to the output rate.

[0049] In this embodiment, the consumption rate of the returned ore material is controlled to be the same as the growth rate. Minerals are added.

Embodiment 3

[0051] On the basis of the above embodiments, the mixing process also includes a retrieving process; the retrieving process: take out the sintered material and the returned ore material at a uniform rate, and control the returned ore material to be evenly added to the sintered material .

[0052]In this embodiment, the sintered material and the returned ore material are taken out at a uniform rate, and then the returned ore material is evenly added to the sintered material. In this way, the returned ore material and the sintered material can be basically in a state of The state of uniform mixing can reduce the working time of mixing equipment and improve production efficiency.

[0053] Example 1

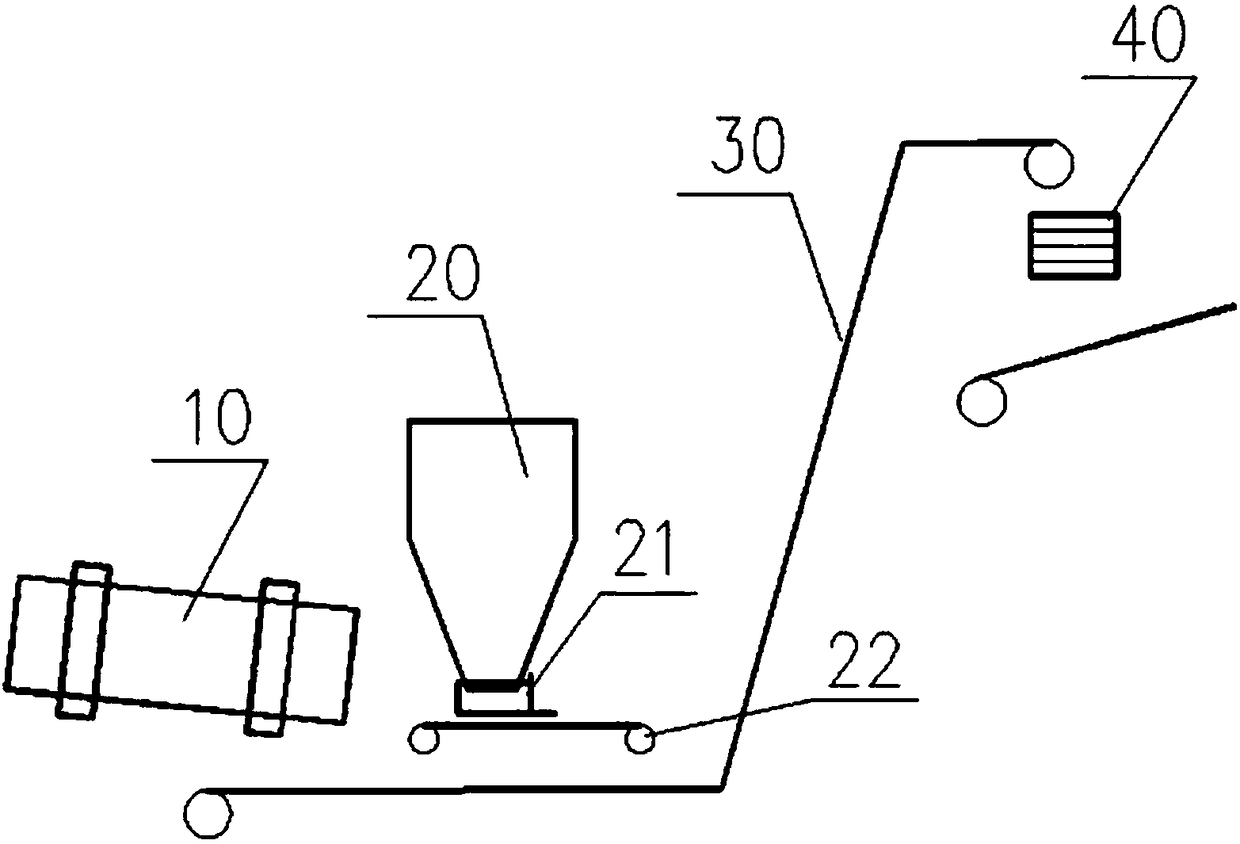

[0054] Such as figure 2 As shown, this embodiment provides a return ore sintering system, including sintering material preparation equipment, intercalation material obtaining equipment and mixing equipment 40; wherein,

[0055] The sinter preparation equipment includes a primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com