Wide-range and high-precision rolling angle measuring device and measuring method

A roll angle measurement, high-precision technology, applied in the field of photoelectric measurement of roll angle, can solve the problems of small measurement range, difficulty in meeting large-scale roll angle measurement, and large volume of the measurement device, so as to improve the range, improve the system measurement range, Measuring Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

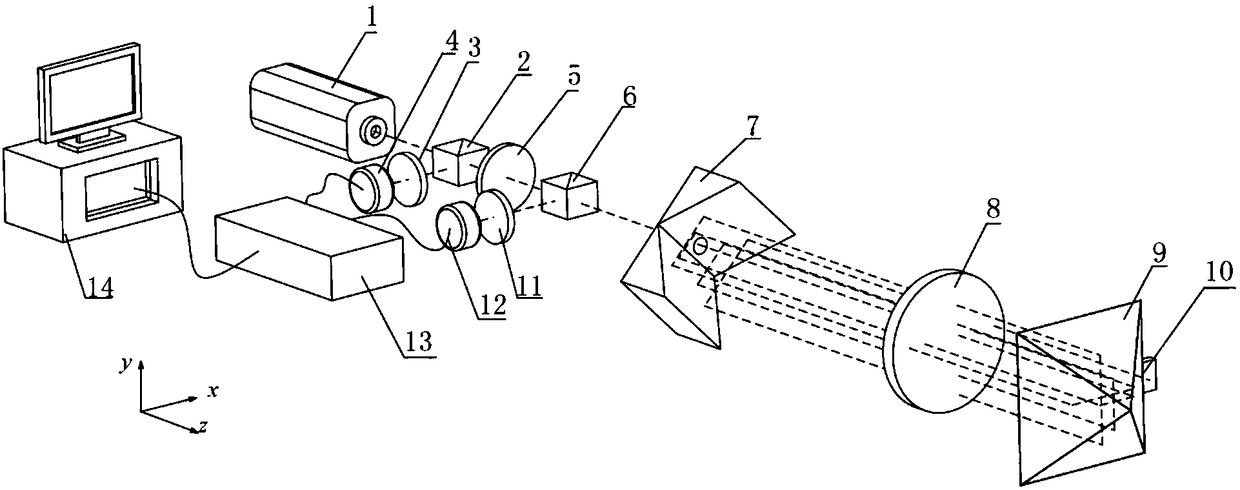

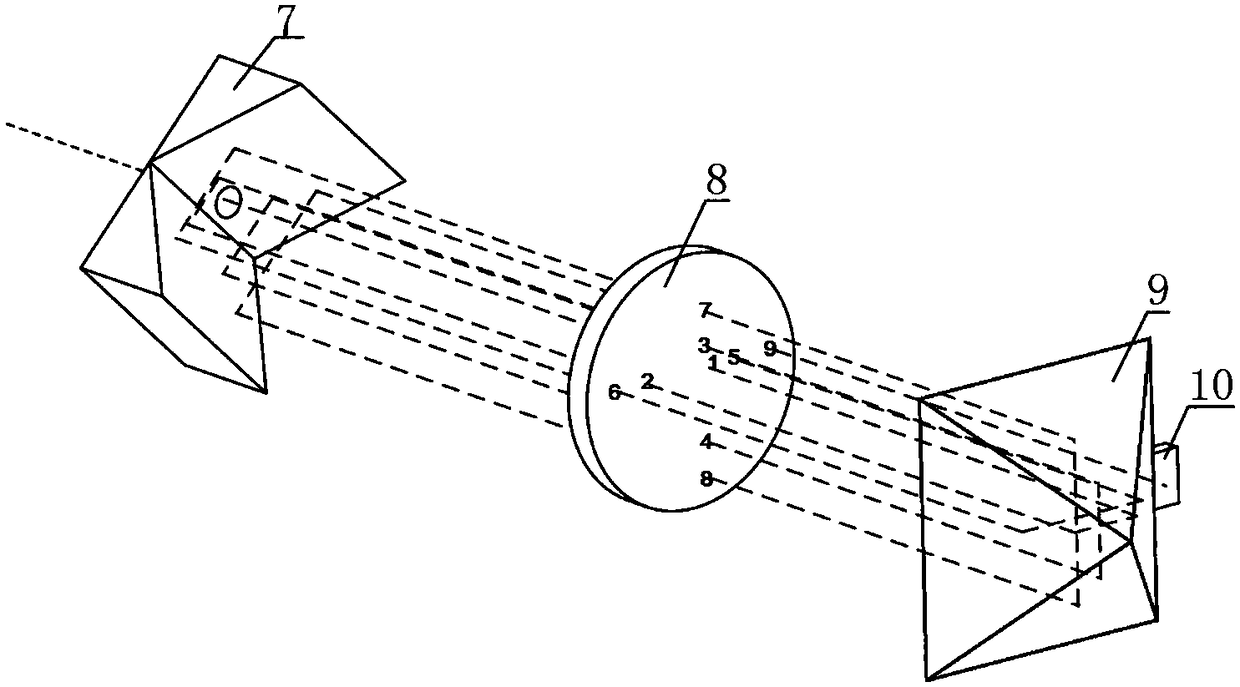

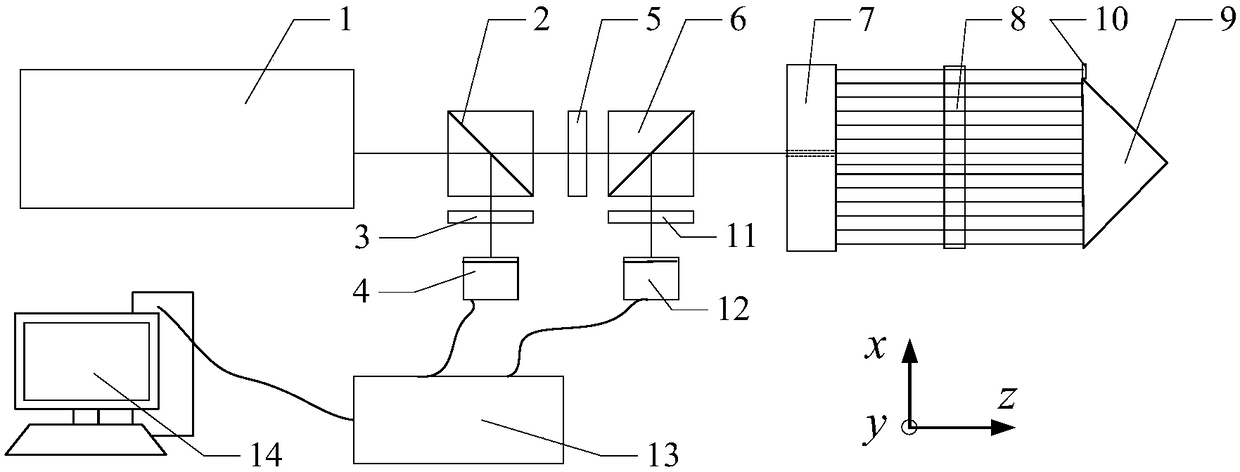

[0033] like Figure 1-7 Shown, a kind of large-scale and high-precision roll angle measuring device is characterized in that, comprises dual-frequency laser 1, beam-splitting prism 2, phase meter 13 and computer 14; The optical axis front end of dual-frequency laser 1 is provided with beam-splitting prism 2, A first polarizer 3 and a first photodetector 4 are sequentially arranged on the reflective optical axis of the beam-splitting prism 2; a quarter-wave plate 5 and a depolarization beam-splitting prism 6 are sequentially arranged on the transmission axis of the beam-splitting prism 2; The transmission optical axis direction of dichroic prism 6 is provided with backward prism reflector 7, 1 / 2 wave plate 8 and quadrangular pyramid reflector 9 successively; The plane reflection mirror 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com